Activated carbon fiber composite material and preparation method thereof as well as activated carbon fiber composite filter element

A technology of activated carbon fibers and composite materials, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It is not resistant to high temperature and other problems, and achieves the effect of overcoming poor strength, large adsorption capacity and uniform microporous structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of activated carbon fiber composite material, comprises the following steps:

[0049] After weighing activated carbon fiber chopped strands and / or activated carbon fiber powder, powdered activated carbon, short fibers, modified cellulose and auxiliary agents to obtain a mixed raw material, the mixed raw material is mixed with water evenly, and is prepared on a paper machine at one time. The net is shaped to form an activated carbon fiber composite material.

[0050] The present invention first weighs the activated carbon fiber chopped strands and / or activated carbon fiber powder, powdered activated carbon, short fiber, modified cellulose and auxiliary agents to obtain the mixed raw material, and then mixes the mixed raw material with water to obtain the mixed slurry material. Wherein, the mass ratio of the mixed raw material to water is preferably 1: (10-20), and in some specific embodiments of the presen...

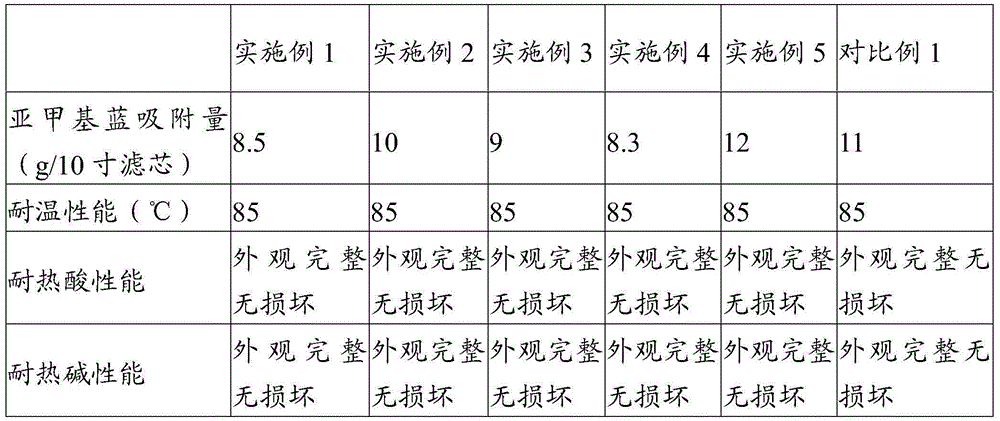

Embodiment 1

[0073] 1. Raw material formula of activated carbon fiber composite material:

[0074] 20wt% activated carbon fiber, purchased from Ningxia Baoda Carbon Fiber Co., Ltd., iodine value 1500mg / g;

[0075]30wt% coconut shell activated carbon with an iodine value of 800mg / g;

[0076] 35wt% wood pulp;

[0077] 10wt% carboxymethyl cellulose;

[0078] 5 wt% polyamide epichlorohydrin.

[0079] 2. Weigh the above materials according to the weight ratio, mix them with water at a ratio of 1:20, and form a net on a paper machine to obtain an activated carbon fiber composite material.

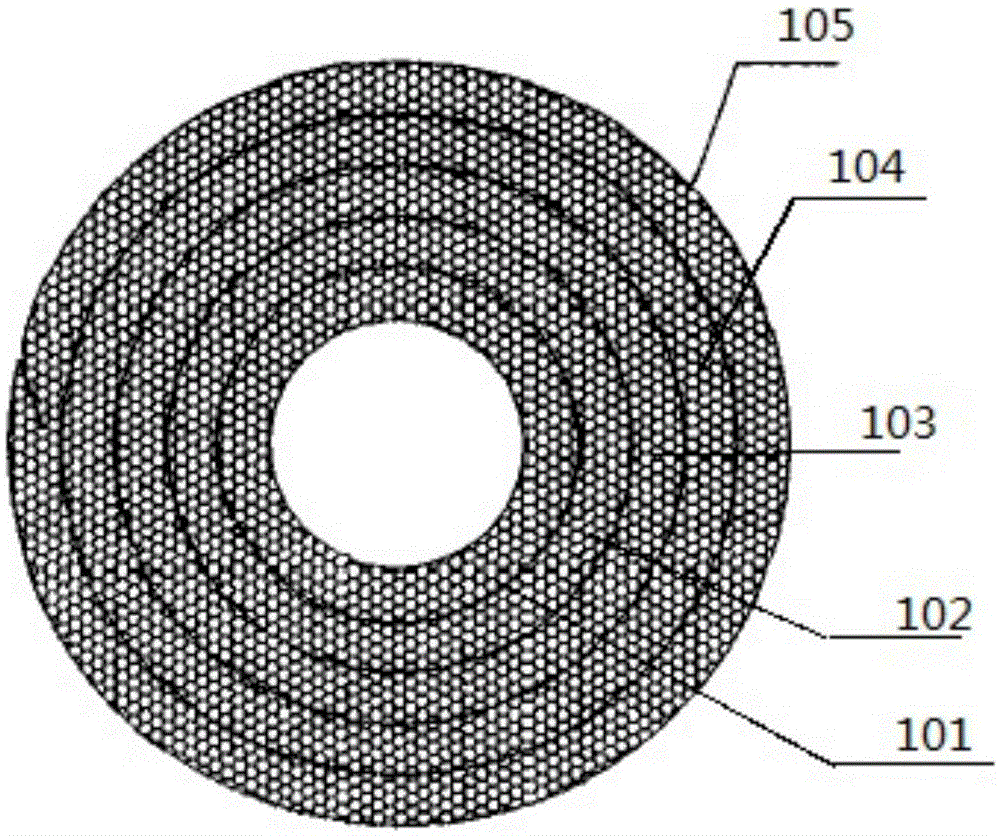

[0080] 3. Cut the activated carbon fiber composite material into a width of 254mm with a circular knife slitting machine, and then cut it into a length of 1200mm, and wind it on a 254mm long hollow cylindrical plastic skeleton covered with polypropylene microfiber cloth. The ethylene protective net and the upper and lower end caps are fixed to make a 10-inch activated carbon fiber composite filter element...

Embodiment 2

[0082] 1. Raw material formula of activated carbon fiber composite material:

[0083] 30wt% activated carbon fiber, purchased from Ningxia Baoda Carbon Fiber Co., Ltd., with an iodine value of 1500mg / g;

[0084] 20wt% coconut shell activated carbon with an iodine value of 800mg / g;

[0085] 35wt% wood pulp;

[0086] 10wt% carboxymethyl cellulose;

[0087] 5 wt% polyamide epichlorohydrin.

[0088] 2. Weigh the above materials according to the weight ratio, mix them with water at a ratio of 1:20, and form a net on a paper machine to obtain an activated carbon fiber composite material.

[0089] 3. Cut the activated carbon fiber composite material into a width of 254mm with a circular knife slitting machine, and then cut it into a length of 1200mm, and wind it on a 254mm long hollow cylindrical plastic skeleton covered with polypropylene microfiber cloth. The ethylene protective net and the upper and lower end caps are fixed to make a 10-inch activated carbon fiber composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com