Chlorosilane-containing waste gas recovery treatment apparatus

A technology for recycling and processing chlorosilanes, which is applied in the direction of halosilanes, silicon halide compounds, lighting and heating equipment, etc., can solve the problems of non-recyclable, corrosive, and large amount of eluent, and improve the recycling rate , reduce processing costs, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

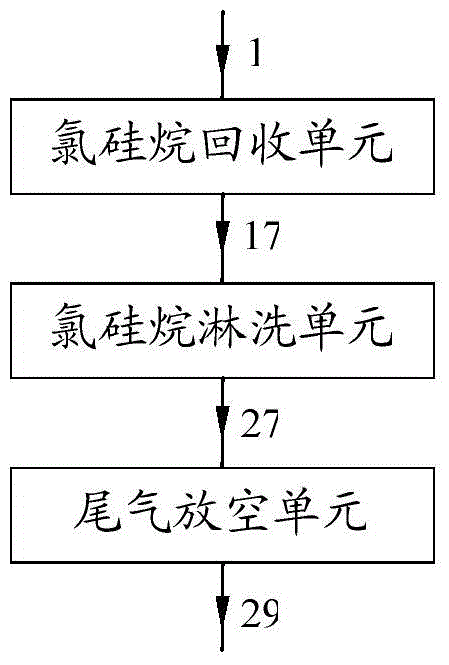

[0030] Such as figure 1 As shown, this embodiment provides a recovery and treatment device for chlorosilane-containing waste gas, including: a chlorosilane recovery unit, a chlorosilane washing unit and a tail gas venting unit.

[0031] Wherein, the chlorosilane waste gas includes nitrogen, hydrogen, hydrogen chloride gas, chlorosilane gas and impurities such as B and P, and the impurities such as B and P include: PCl 3 (phosphorus trichloride), PCl 5 (phosphorus pentachloride), BCl 5 (boron pentachloride) and PH 3(phosphine), and chlorides of B (boron), P (phosphorus); chlorosilane (chlorosilane) is silane (SiH 4 ) in which hydrogen atoms are replaced by chlorine atoms, which is a gas when the chlorine content is low, and a liquid when the chlorine content is high, and the general formula is SiH n Cl 4-n , n=0,1,2,3.

[0032] The chlorosilane recovery unit is connected with the chlorosilane washing unit, and is used for recovering part of the chlorosilane gas in the chl...

Embodiment 2

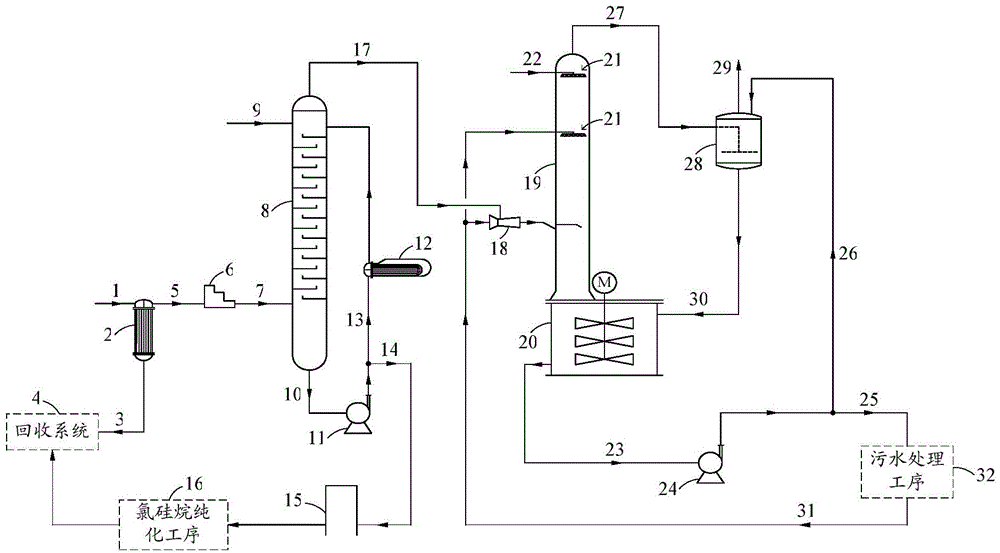

[0055] Such as figure 2 As shown, this embodiment provides a recycling and processing device for chlorosilane-containing waste gas, including: a frozen brine precooler 2, a booster 6, an absorption tower 8, a circulation pump 11, a deep cooler 12, a resin adsorption column 15, Mixing subunit 18, rinsing tower 19, stirring subunit 20, spray head 21, booster pump 24, water seal tank 28.

[0056] The working principle of the recovery treatment device is:

[0057] After the chlorosilane waste gas 1 enters the frozen brine precooler 2, part of the chlorosilane gas forms a chlorosilane condensate 3, and is delivered to the recovery system 4, while the remaining chlorosilane waste gas 5 (i.e. not described in Example 1) The chlorine-containing silane exhaust gas that forms condensate) enters the booster 6, and after being pressurized by the booster 6 to 0.05MPaG-0.2MPaG, it becomes a high-pressure exhaust gas 7. After the high-pressure exhaust gas 7 enters the absorption tower 8, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com