Cleaning, de-rusting and cutting automatic conversion all-in-one machine for offshore oil platform

An offshore oil, automatic conversion technology, applied in abrasive jet machine tools, cleaning methods and utensils, cleaning methods using liquids, etc. problem, to achieve the effect of light weight, saving fresh water and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

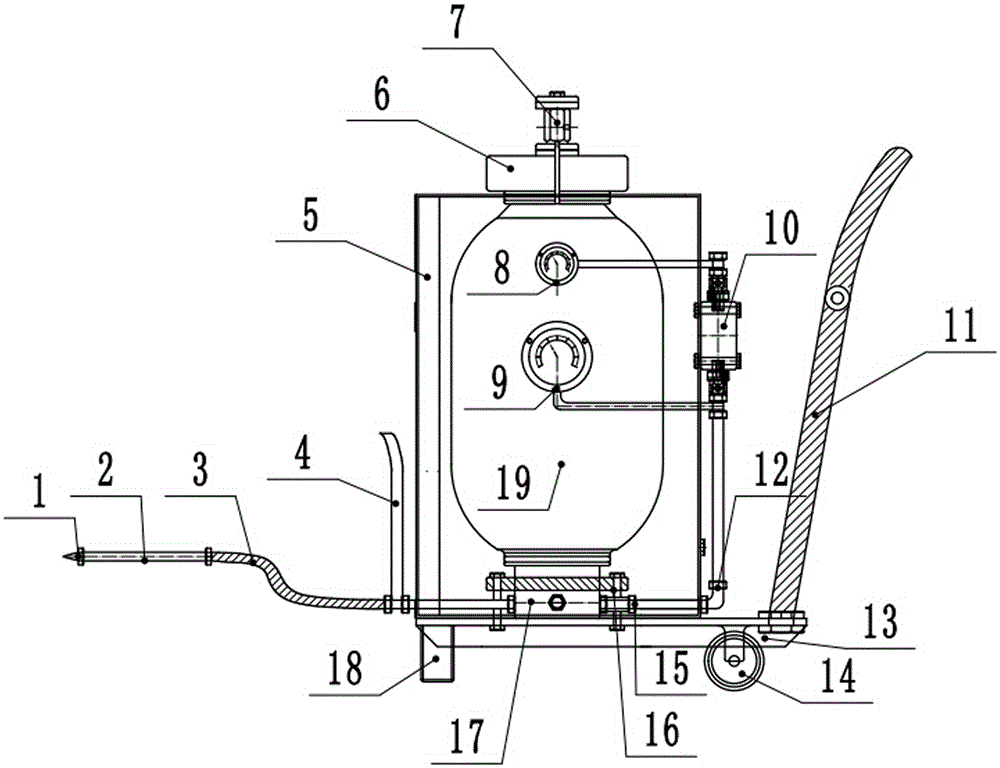

[0016] Such as figure 1 As shown, the offshore oil platform cleaning, derusting, and cutting automatic conversion integrated machine described in the embodiment of the present invention includes (1) jewel nozzle, (2) spray gun handle, (3) high-pressure rubber hose, (4) sand amount adjustment handle, (5) Protective cover, (6) End cap, (7) Pressure relief valve, (8) Inlet pressure gauge, (9) Working pressure gauge, (10) Pressure flow control valve, (11) Push handle, (12) High-pressure liquid inlet pipe, (13) base, (14) casters, (15) one-way valve, (16) balance water adjustment knob, (17) mixing valve assembly, (18) leg, (19) abrasive tank; It is characterized in that: the pressure and flow control valve (10), the liquid inlet pressure gauge (8), and the working pressure gauge (9) are sequentially installed on the protective cover (5); the pressure relief valve (7) is screwed on the end cover (6); the end cover, the mixing valve assembly (17) and the abrasive tank (19) are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com