Method for machining omega weld joint groove in lower portion of CRDM of nuclear power plant and cutter

A CRDM, weld groove technology, applied in manufacturing tools, metal processing equipment, tools for lathes, etc., can solve the problems of affecting welding quality, low reliability, and difficult to guarantee dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

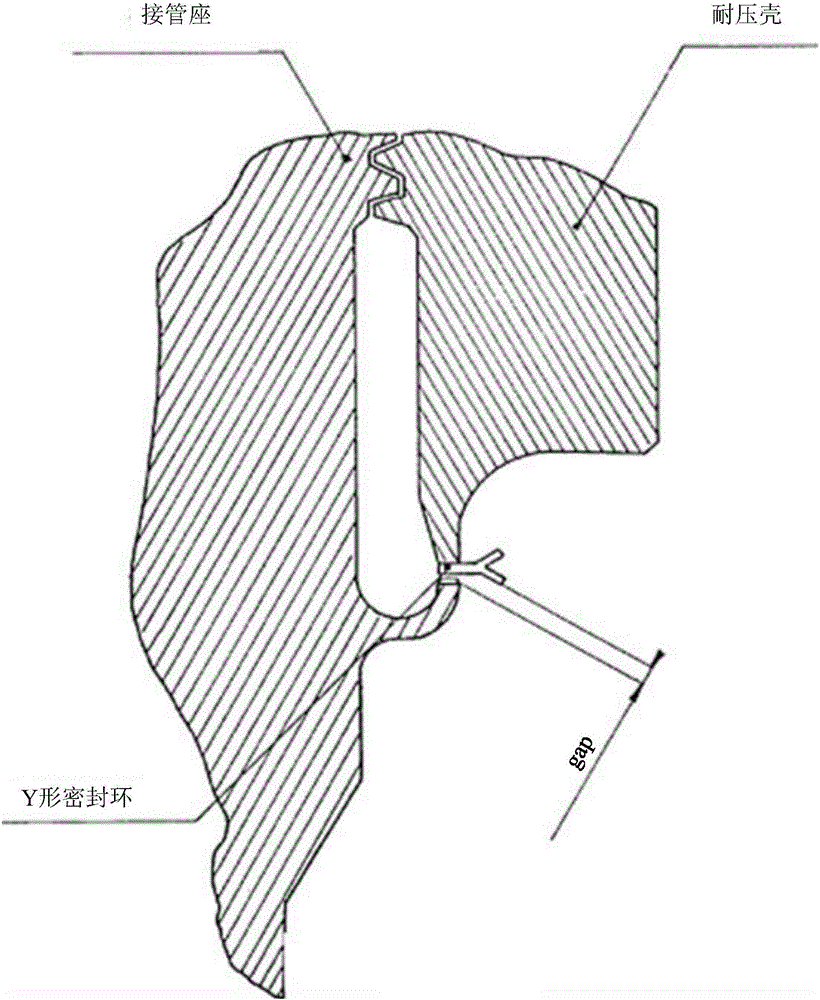

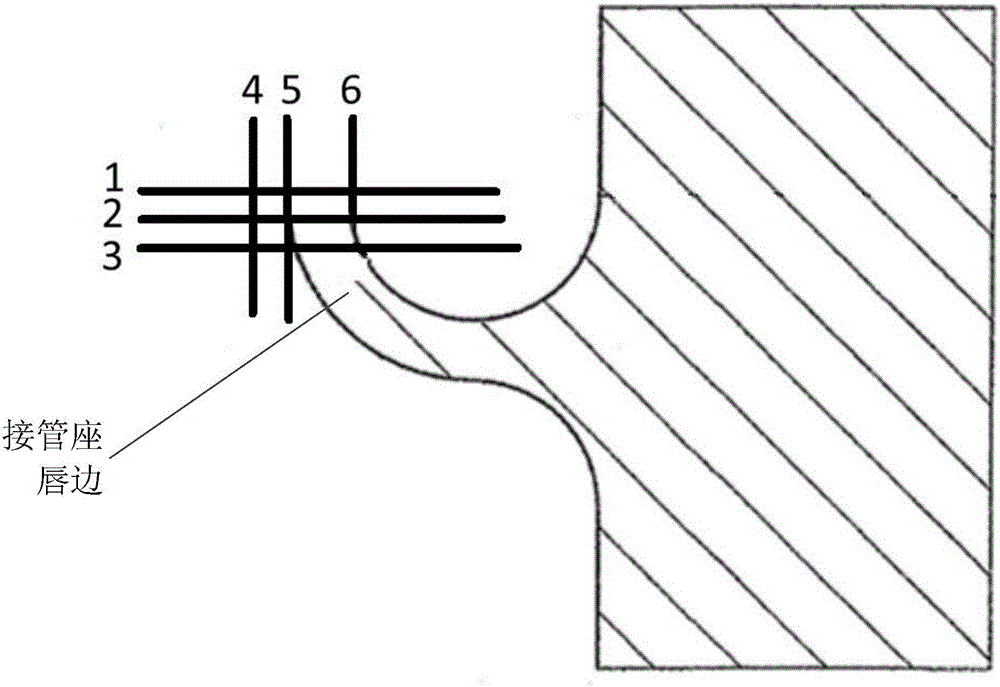

[0046] Please refer to Figure 4 and Figure 5 , the embodiment of the present invention provides a Ω weld bevel processing tool for the lower part of the CRDM of a nuclear power plant, the Ω weld B is a weld formed between the CRDM and the lip A of the reactor pressure vessel top cover through Ω seal welding, and the Ω weld B is formed by Ω seal welding. Knives include:

[0047] The cutting part 1 includes: a first machining knife surface 11 for cutting the weld residue on the inner side of the lip A of the socket, wherein the first machining knife surface 11 is arc-shaped; The second processing knife surface 12 for cutting the weld residue on the upper part of the lip A of the adapter seat; the third machining cutter surface 13 for cutting the weld residue on the outer side of the lip A of the adapter seat;

[0048] The clamping part 2 fixedly connected to the cutting part 1 is used to be fixedly connected to the rotary head of the tool driving device, and driven by the ro...

Embodiment 2

[0053] Based on the same invention concept, please refer to Figure 7 , the embodiment of the present invention also provides a method for processing the Ω weld bevel at the lower part of the CRDM of a nuclear power plant, which is applied to the tool drive equipment, and the Ω weld is CRDM and the reactor pressure vessel top cover connecting pipe seat lip A through Ω seal welding The formed weld seam, the tool driving device is used to drive the Ω weld bevel processing tool at the lower part of the CRDM of the nuclear power plant to cut the weld seam residue on the lip A of the socket. Processing cutter face 12 and the 3rd processing cutter face 13; Described groove processing method comprises the following steps:

[0054] S1. After the tool is fixedly clamped on the rotating machine head of the tool driving device, detect and adjust the concentricity between the tool driving device and the socket, so that the tool driving device and the socket The concentricity of the seat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com