Loaded phthalocyanine cobalt sulfonate activated carbon desulfurization adsorbent and preparation method thereof

A technology of phthalocyanine cobalt sulfonate and activated carbon, which is applied in the direction of selective adsorption, separation method, adsorption purification/separation, etc., can solve the problems of low penetration sulfur capacity of desulfurizer and low sulfur removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

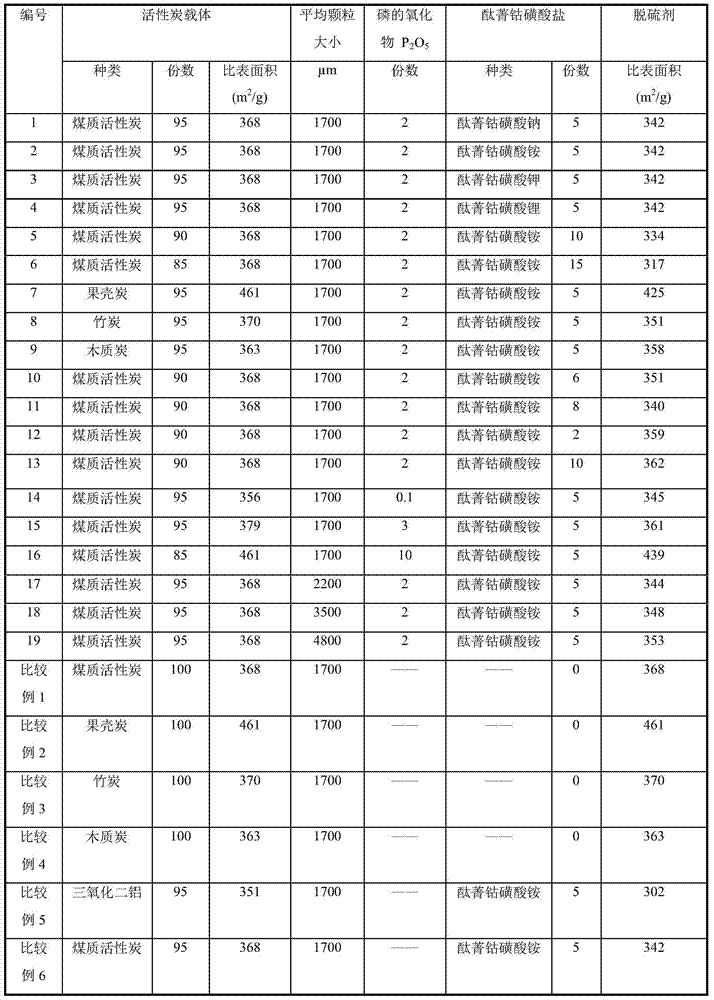

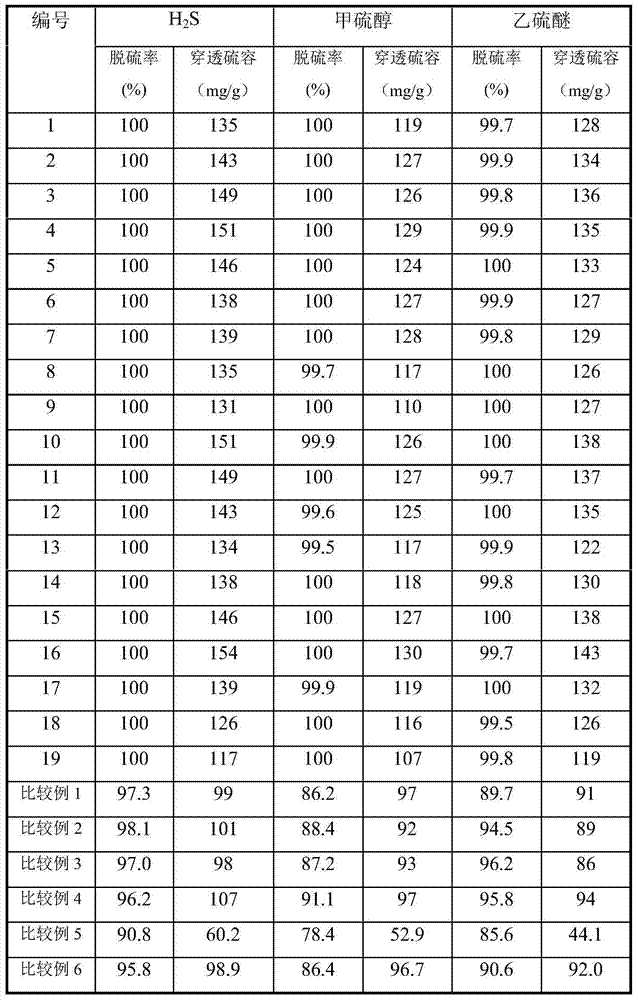

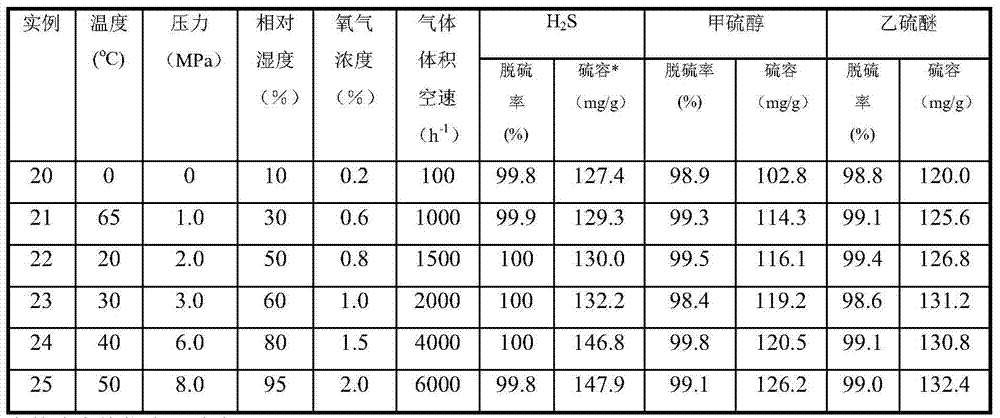

Examples

Embodiment 1

[0027] The impregnated modified activated carbon adsorbent loaded with sodium phthalocyanine cobalt sulfonate is prepared according to the same amount of impregnation as follows. First, weigh 11.4 g of sodium phthalocyanine cobalt sulfonate, add it into 80 ml of deionized water and dissolve it, and prepare solution I containing sodium phthalocyanine cobalt sulfonate. Add 2.3ml of 86% H in solution I 3 PO 4 . Then add 17.7ml of water to prepare sodium phthalocyanine cobalt sulfonate with a molar concentration of 0.2mol / L and PO 4 3- Solution II with a concentration of 0.20mol / L. Through preliminary experiments, the water absorption rate of activated carbon was measured to be 50%. Accurately weigh 100g of activated carbon, and according to the water absorption rate measured above, take 50ml of the above-prepared solution II, pour the solution into a container containing activated carbon, stir well, and mix evenly. After drying in the air, drying, roasting at 500°C for 8 ho...

Embodiment 2

[0030] The impregnated modified activated carbon adsorbent loaded with ammonium phthalocyanine cobalt sulfonate is prepared according to the same amount of impregnation as follows. First, 11.3 g of ammonium phthalocyanine cobalt sulfonate was weighed and dissolved in 80 ml of deionized water to prepare solution I containing ammonium phthalocyanine cobalt sulfonate. Add 2.3ml of 86% H in solution I 3 PO 4 . Then add 17.7ml of water to prepare ammonium phthalocyanine cobalt sulfonate with a molar concentration of 0.2mol / L and PO 4 3- Solution II with a concentration of 0.20mol / L. Through preliminary experiments, the water absorption rate of activated carbon was measured to be 50%. Accurately weigh 100g of activated carbon, and according to the water absorption rate measured above, take 50ml of the above-prepared solution II, pour the solution into a container containing activated carbon, stir well, and mix evenly. After drying in the air, drying, roasting at 500°C for 8 ho...

Embodiment 3

[0033] The impregnated modified activated carbon adsorbent loaded with potassium phthalocyanine cobalt sulfonate is prepared according to the same amount of impregnation as follows. First, weigh 11.7 g of potassium phthalocyanine cobalt sulfonate, add it into 80 ml of deionized water and dissolve it, and prepare solution I containing potassium phthalocyanine cobalt sulfonate. Add 2.3ml of 86% H in solution I 3 PO 4 . Then add 17.7ml of water to prepare potassium phthalocyanine cobalt sulfonate with a molar concentration of 0.2mol / L and PO 4 3- Solution II with a concentration of 0.20mol / L. Through preliminary experiments, the water absorption rate of activated carbon was measured to be 50%. Accurately weigh 100g of activated carbon, and according to the water absorption rate measured above, take 50ml of the above-prepared solution II, pour the solution into a container containing activated carbon, stir well, and mix evenly. After drying in the air, after drying, roasting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| breakthrough sulfur capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com