Application of magnesium material as oral cavity GTR or GBR membrane material

A membrane material, magnesium alloy technology, applied in the field of oral GTR or GBR membrane materials, can solve the problems of acidic environment, easy to cause inflammatory reaction, poor mechanical strength, fast degradation rate, etc., to ensure biological safety and improve the physical barrier effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

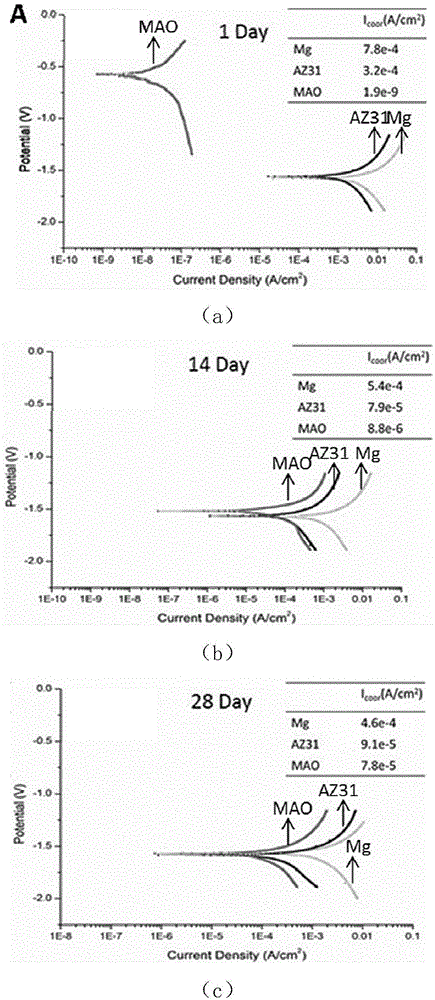

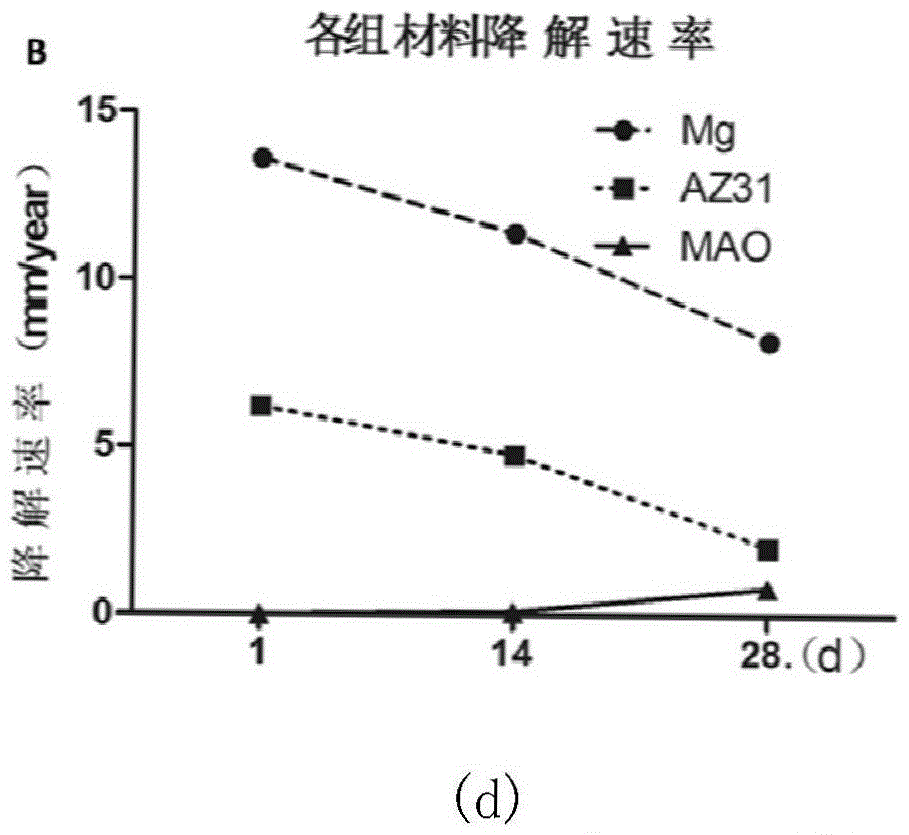

[0029] 1) Use pure magnesium and AZ31 magnesium alloy to make a 0.1mm thick film;

[0030] 2) Step 1) After the surface polishing of the three membrane materials, they were ultrasonically cleaned with acetone, absolute ethanol and deionized water for 30 minutes in sequence, and dried;

[0031] 3) Preparation of micro-arc oxidation electrolyte: deionized water is used as solvent, prepared as 0.8g / L NaOH, 3.5g / L (NaPO 3 ) 6 and 8g / L KF mixture;

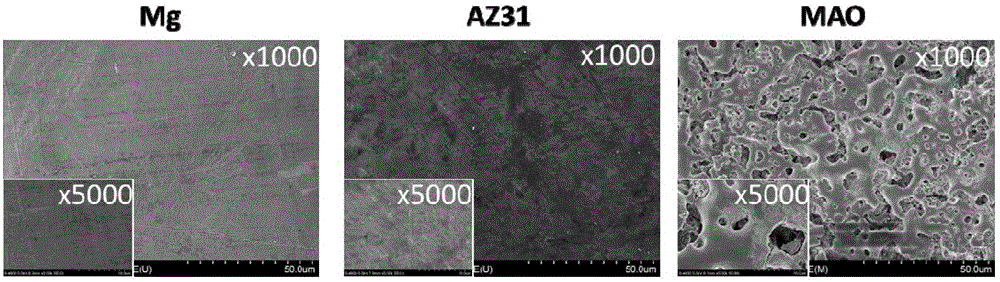

[0032] 4) Preparation of micro-nano porous coating by micro-arc oxidation method: AZ31 magnesium alloy film is used as the anode, stainless steel is used as the cathode, a composite pulsed micro-arc oxidation bipolar power supply with a power of 2kW is selected, the set voltage is 360V, the working frequency is 1000Hz, the intensity 40%, the processing time is 5 minutes;

[0033] 5) After the preparation is completed, ultrasonically clean with acetone, absolute ethanol and deionized water for 30 minutes in sequence, and dry;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com