Nose prosthesis and manufacturing method thereof

A nasal prosthesis and nose bridge technology, applied in the field of nasal prosthesis, can solve the problems of nasal prosthesis movement, nose plastic deformation, etc., and achieve the effect of high hardness, low hardness and easy growth of the outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

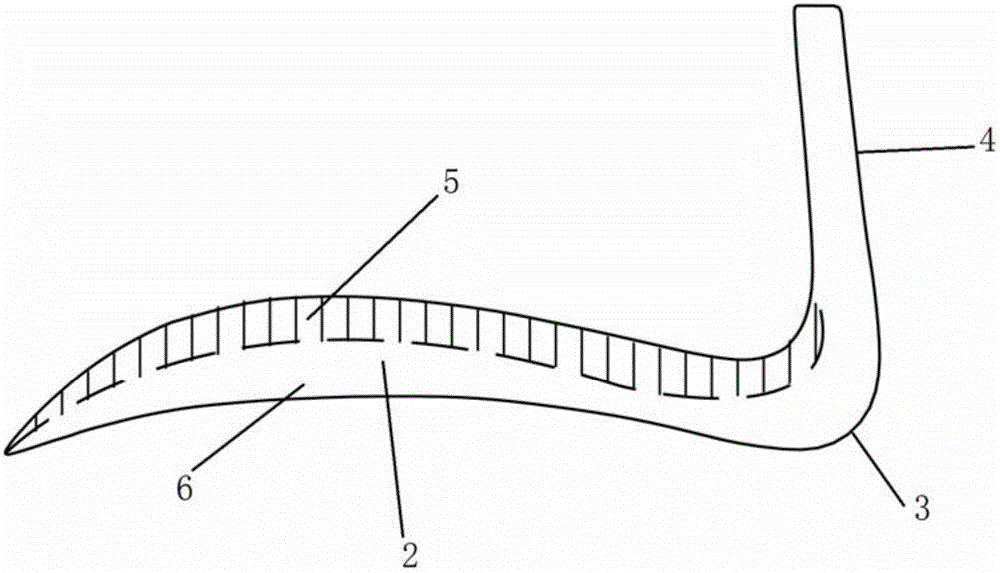

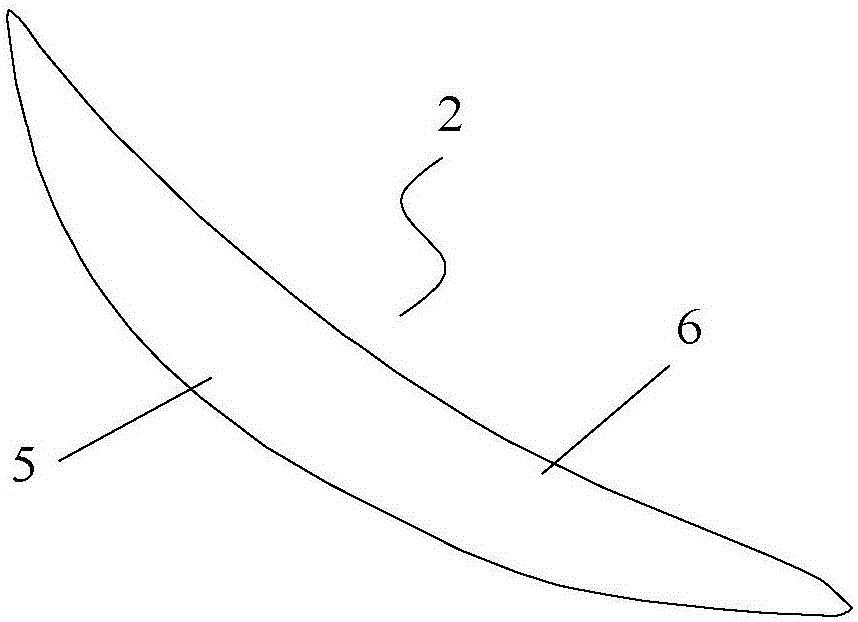

[0054] Such as Figure 5 As shown, the nasal prosthesis 1 of the present invention includes a bridge of the nose 2, a tip of the nose 3, and a columella 4. The bridge of the nose 2 is provided with a fixing structure, and the fixing structure is an array arranged along the fitting surface 5 of the bridge of the nose 2 toward the outer surface 6 of the bridge of the nose. Through hole 11.

[0055] Such as Figure 10 As shown, in this embodiment, the array through holes 11 are arranged along the entire bonding surface 5 . The advantage of adopting this arrangement method of the arrayed through holes 11 is that the bonding surface 5 and the outer surface 6 of the bridge of the nose 2 can be well combined with the muscular tissue of the bridge of the nose and the skin tissue of the bridge of the nose on the entire surface. Disadvantages: First, there are incomplete holes with sharp edges on the peripheral edge of the bridge of the nose. This part of the structure is fitted with ...

Embodiment 2

[0061] Such as Image 6 As shown, the fixing structure on the bridge of the nose of the nasal prosthesis in this embodiment is as follows: an array of through holes 11 is provided along the fitting surface 5 of the nose bridge to the outer surface 6 of the bridge of the nose, and an array of counterbores 12 is arranged on the side of the fitting surface 5 of the nose bridge. The holes of the counterbore 12 and the holes of the arrayed through holes 11 are alternately arranged at intervals.

[0062] In this embodiment, the arrayed counterbore 12 is arranged on the side of the nose bridge fitting surface 5. On the one hand, the hardness of the nose bridge fitting surface 5 is reduced to ensure that the nose bridge fitting surface 5 fits well with the musculature of the bridge of the nose of the human body, while ensuring that the outer surface of the bridge of the nose is relatively tight. The fitting surface has higher hardness and meets the shaping requirements; on the other h...

Embodiment 3

[0067] Such as Figure 7 As shown, the fixing structure on the bridge of the nose of the nasal prosthesis of this embodiment is: an array column 13 arranged on one side of the nose bridge fitting surface 5, and the top surface of the array column 13 constitutes the nose bridge patch on which the array column 13 is arranged. Part of surface 5.

[0068] Because the array column 13 is made of many independent columns, the end of each column is a free end, which is easy to deform, and the strength and hardness of each column can be adjusted by changing the lateral size and height of the column. The cross-sectional shape of the column Circular, square or polygonal, etc. can be used. The fixed structure adopts an array column 13 structure on one side of the nose bridge fitting surface 5, which can obtain a softer nose bridge fitting surface, ensure a good fit between the nose bridge fitting surface and the human nose bridge musculature, and ensure that the outer side of the nose br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com