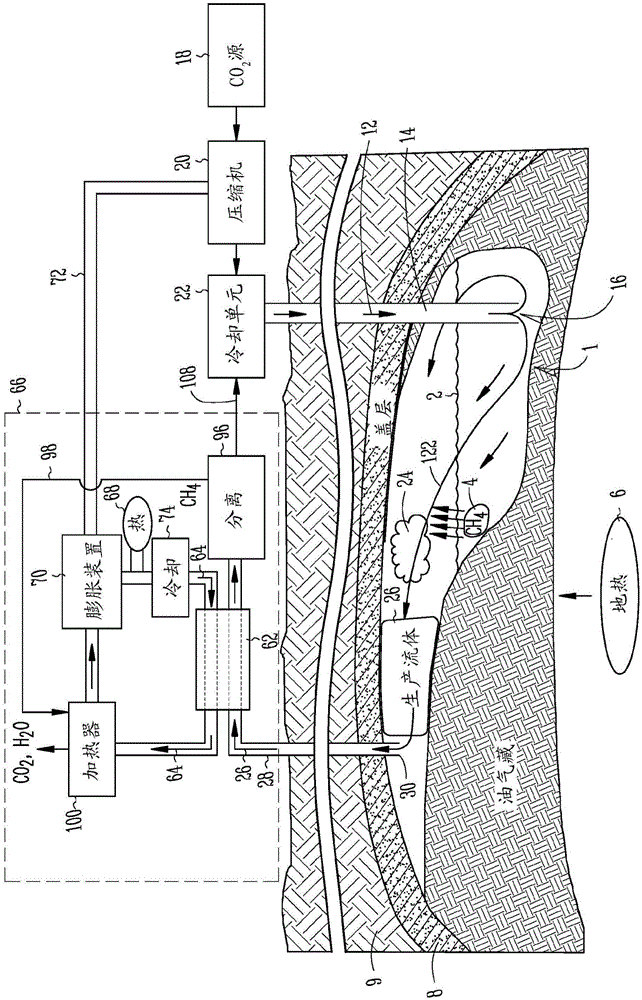

Enchanced carbon dioxide-based geothermal energy generation systems and methods

A carbon dioxide and energy technology, applied in the field of enhanced carbon dioxide base thermal energy generation systems and methods, can solve problems such as high cost and low overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0188] Figure 11A Shown is the electricity generated in megawatts (MW) depending on the wellhead temperature of the working fluid or production fluid once produced to the surface. Figure 11B The generated electricity is shown as a function of bottomhole temperature. Wellhead temperature ( Figure 11A ) and bottomhole temperature ( Figure 11B ) is due to Joule-Thompson cooling, which occurs when fluid pressure decreases during fluid ascent in a production well, so that the bottomhole temperature and pressure of the fluid are greater than the wellhead temperature and pressure. Considering that the Joule-Thompson behavior does not occur in the water-based thermal working fluid, the computationally generated Figure 11A and Figure 11B .

[0189] The modeling assumes a reservoir depth of 1500 meters and a production fluid flow rate of 200kg / s, where the production fluid is 99wt% CO 2 and 1 wt% methane, of which 2.0 kg / s methane is separated and combusted to increase the t...

Embodiment 2

[0194] relatively free of CO 2 Capture (data line 310) and ME-CPG systems with carbon dioxide capture (data line 312), CPG-only geothermal energy recovery (data line 314), and methane-only combustion without CO 2 capture (data line 316), and with CO 2 capture (data line 318), Figure 12A and Figure 12B shows that similar data are obtained, but at a reservoir depth of 2500 m rather than at Figure 11A and Figure 11B 1500 meters in.

Embodiment 3

[0196] Figure 13 The electricity generated in megawatts (MW) is shown as a function of the wellhead temperature of the production fluid. Figure 13 Includes data from methane-enhanced geothermal energy production for EOR applications, where geothermal energy is recovered from CO 2 The compressor is further supplemented by waste heat capture.

[0197] The modeling in this embodiment assumes a reservoir depth of 1500 meters and a production fluid flow rate of 100 kg / s. Assuming the production fluid is 20 wt% CO 2 , 1 wt% methane, and the rest are liquid hydrocarbons and brine. The flow rate of methane separated from the production fluid and combusted is assumed to be 0.5 kg / s. The energy recovery system for the EOR system is assumed to be a binary system with a second working fluid, making energy recovery less efficient than the direct turbine systems that can be used in Example 1 and Example 2. Therefore, it is assumed that the energy recovery system has a power system ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com