Device and method for replacing vibration motors

A technology of vibrating motors and moving trolleys, applied in electromechanical devices, manufacturing motor generators, lifting devices, etc., can solve the problems of increased safety risk factor, increased work-related injury rate, time waste, etc., to improve installation convenience and improve work efficiency , Easy and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

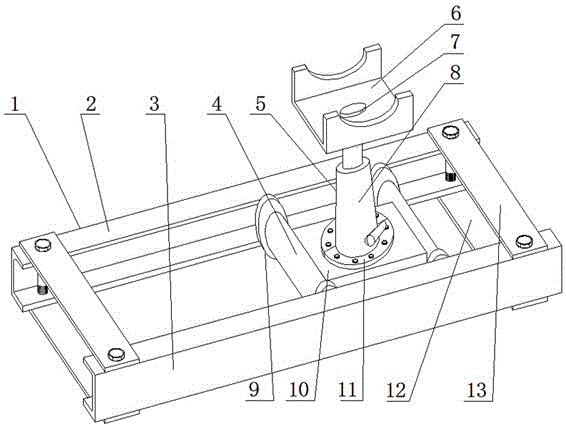

[0032] see figure 1 , including driving track 1, mobile trolley 4, lifting mechanism 5 and bracket 6, driving track 1 includes first channel steel 2 and second channel steel 3, the upper end faces of first channel steel 2 and second channel steel 3 both sides The upper baffle 13 and the lower baffle 12 are respectively fixedly connected. The upper baffle 13 is processed with two holes with a diameter of 22mm, and the lower baffle 12 is processed with two threads of M20mm corresponding to the upper baffle 13. Holes, the first channel steel 2 and the second channel steel 3 respectively correspond to the upper baffle plate 13 and the lower baffle plate 12 and are processed with a hole with a diameter of 22mm and a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com