Insulated wire and cable

A technology for insulating wires and cables, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of decreased mechanical properties, decreased melt fluidity, limited molding machine, etc., and achieves the effect of preventing mold slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

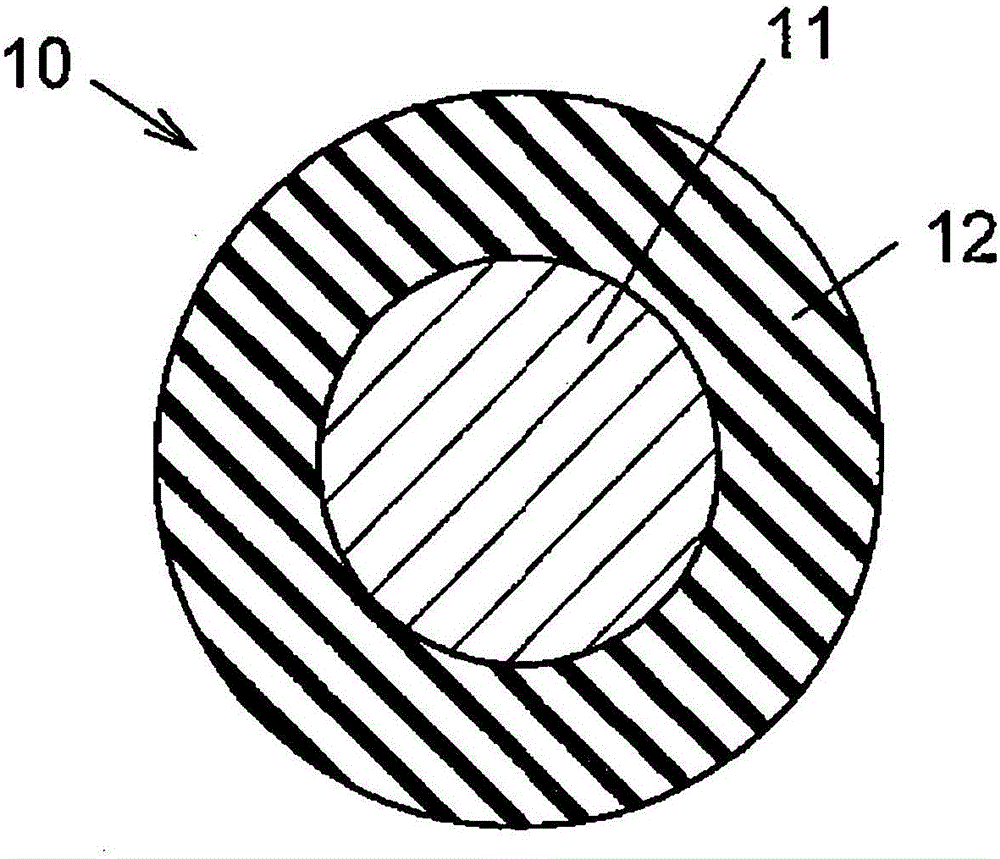

Image

Examples

Embodiment 1~5 and comparative example 1~6

[0079] Examples 1 to 5, Comparative Examples 1 to 6, and Conventional Examples

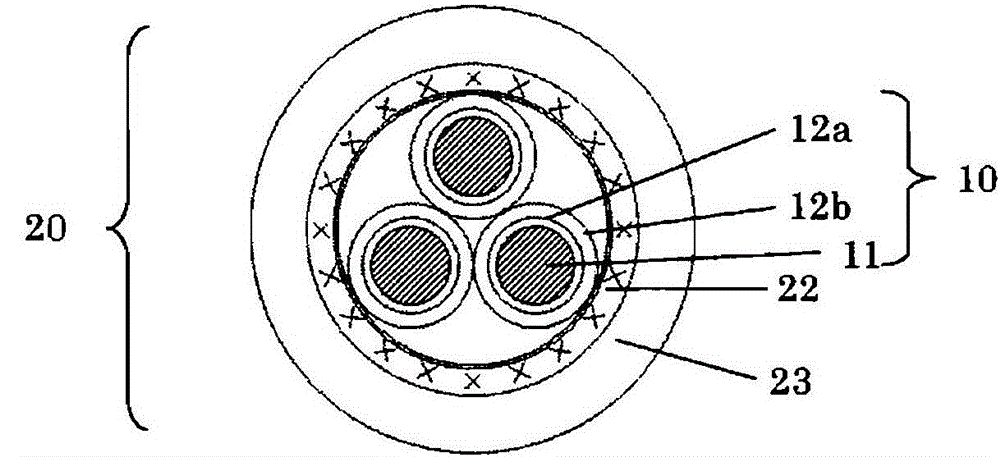

[0080] made by figure 2 cables shown.

[0081] (1) On the outer circumference of the conductor twisted by 19 bare wires of 0.18mm, as an insulating layer, use a 65mm extruder at 150°C to extrude 0.1mm of coated polyethylene as the inner layer, and extrude the coated polyethylene naphthalene 0.15 mm of butylene glycol formate was used as the outer layer, and then cross-linked by irradiation with electron beams of 10 Mrad to obtain an insulated wire. Three obtained insulated electric wires were twisted to prepare a three-core twisted wire.

[0082] (2) Prepare the various components shown in Table 1, knead them with a pressurized kneader at a starting temperature of 40°C and an ending temperature of 20°C, and then make them into granules (granulation) as a sheath material .

[0083] (3) The obtained cables were evaluated by various evaluation tests shown below. The evaluation results are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com