Method for distinguishing geometrical characteristic changes generated before and after integral panel part engineering is changed

A technology of integral siding and geometric features, applied in special data processing applications, instruments, electrical and digital data processing, etc. The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

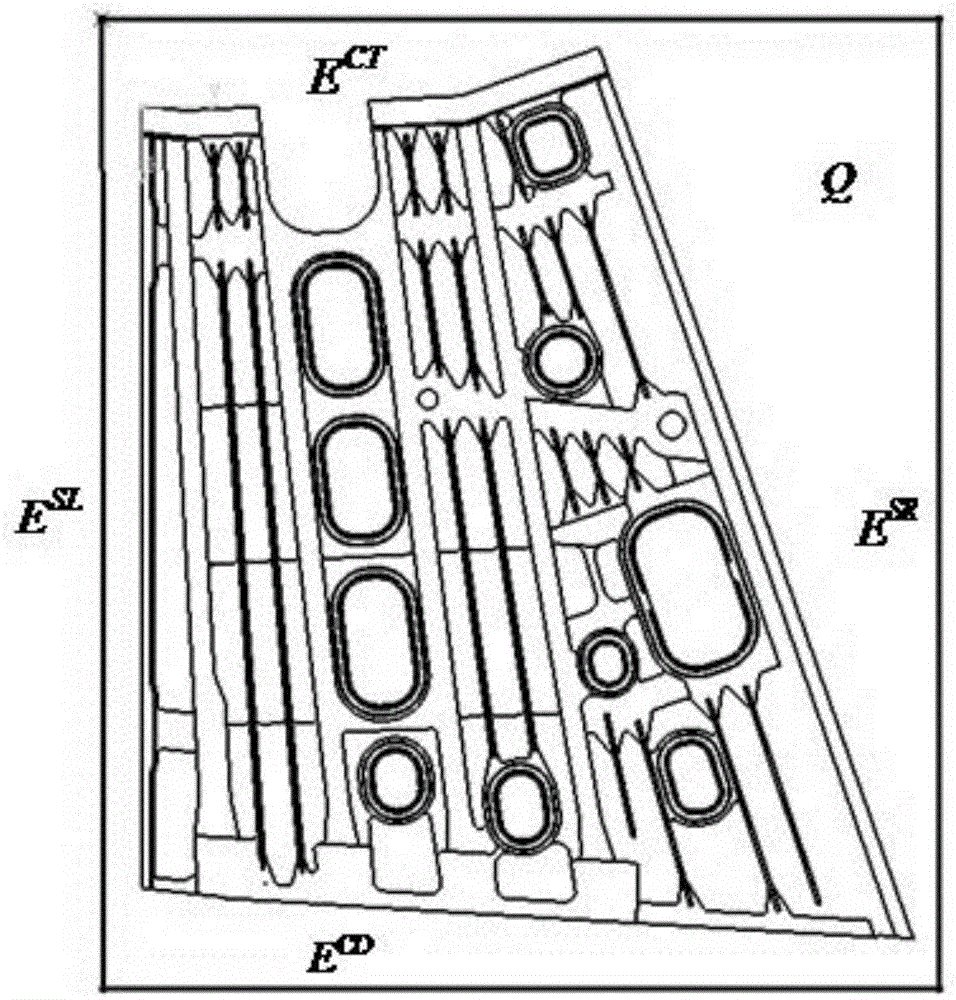

[0027] The present invention is further illustrated below in conjunction with the accompanying drawings and examples.

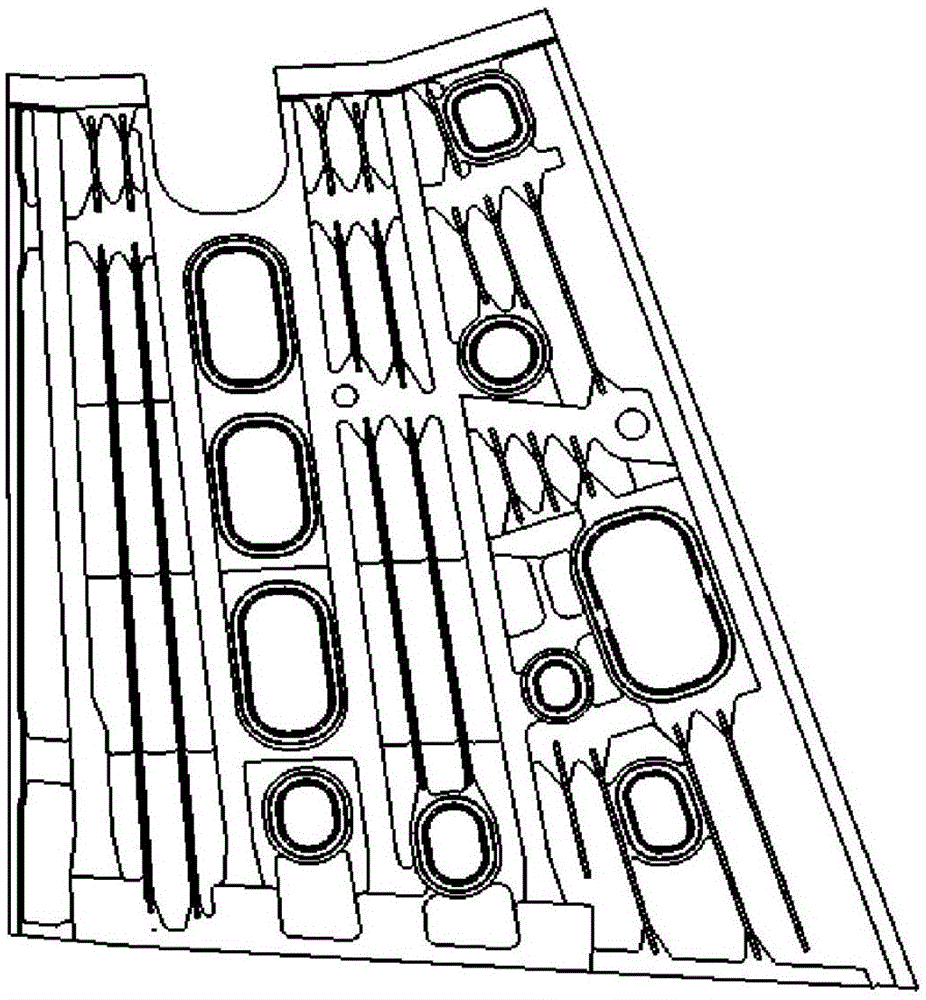

[0028] by figure 1 Taking the design model of integral wall panel part as an example, combined with the accompanying drawings, the specific implementation process of a method for discriminating the change of geometric characteristics before and after engineering modification of integral wall panel parts is described.

[0029] Use the thickness dimension of the model as a comparison element to compare the geometric shape of the design model before and after the change to judge the change position.

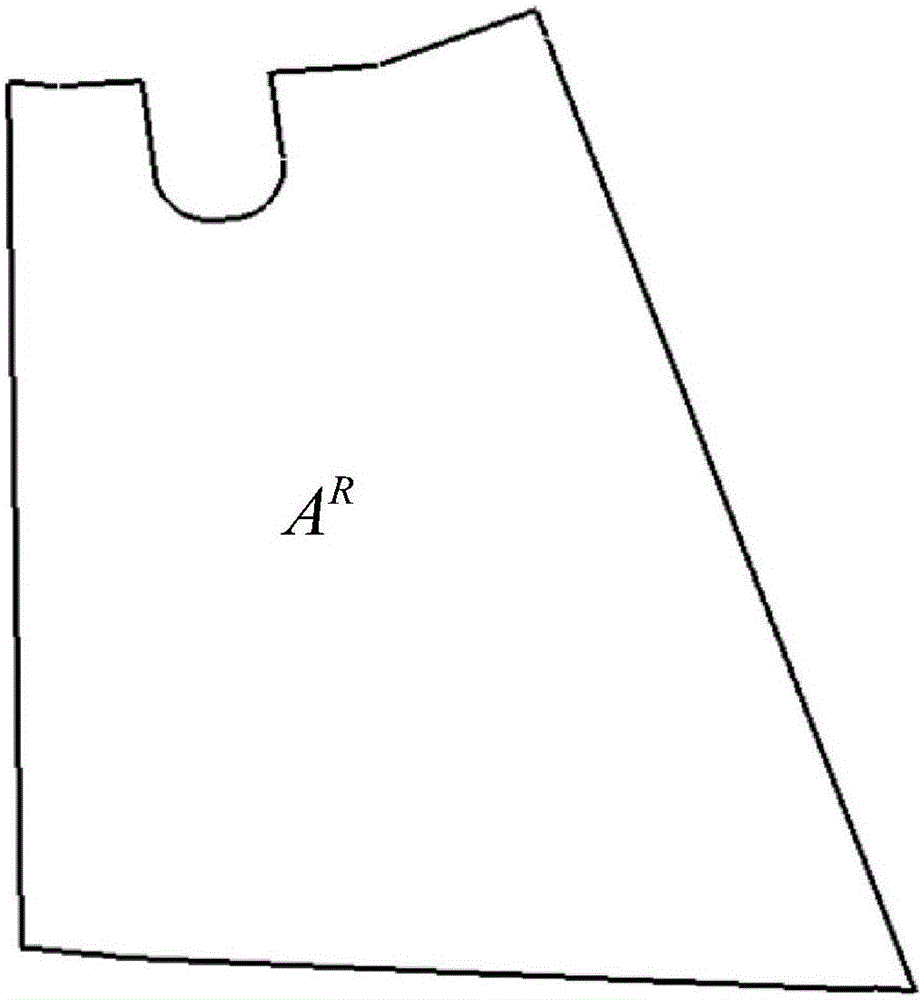

[0030] Step a: Properly extend the outer surface of model A so that it can simultaneously envelop the outer surface of model A and model B, as a discrete surface, denoted as A R ,Such as figure 2 shown;

[0031] Step b: Set the span direction vector that can envelop the outline of the model to be compared chord direction vector To intercept an envelope alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com