Foam flooding evaluation device and evaluation method thereof

A technology of foam flooding and evaluation device, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as lack of basic and accurate and stable indoor simulation experimental devices, uncontrollable gas-liquid ratio, and inability to guarantee gas-liquid ratio. , to achieve the effect of good simulation effect, reliable working performance and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Example 1 (foam flooding evaluation device)

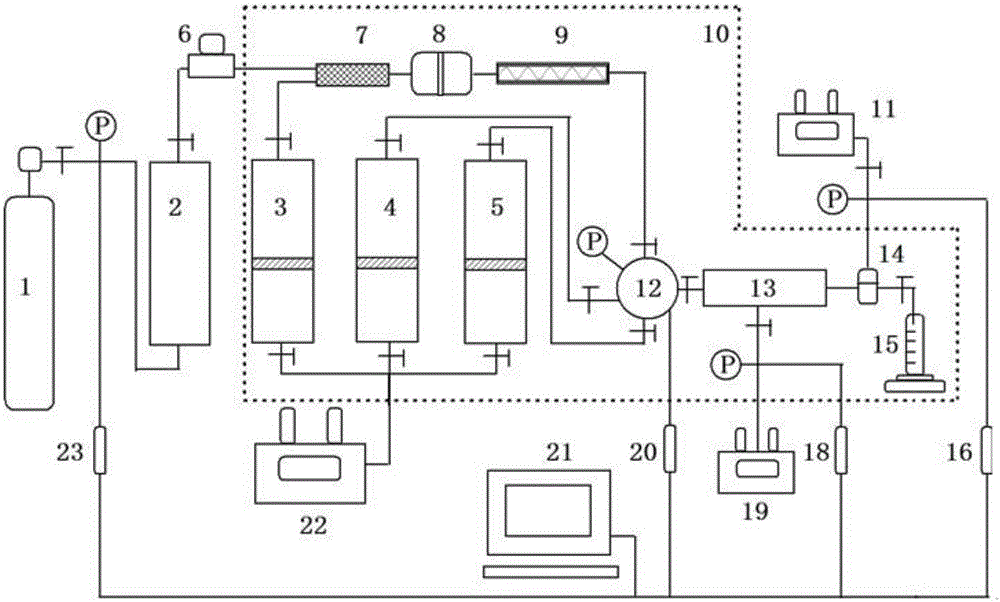

[0043] A foam flooding evaluation device, including a foam generating device, a liquid supply device, a core simulation device and a data acquisition system, wherein:

[0044] The foam generating device comprises a gas storage cylinder 1, a buffer gas cylinder 2, a gas flow controller 6, a foam generator 7, a foam storage tank 8 and a screw pump 9 which are sequentially communicated through a connecting pipeline;

[0045] The liquid supply device includes a piston container 3 for foaming liquid, a piston container 4 for formation water, a piston container 5 for crude oil, and a plunger pump 22. The plunger pump 22 is connected to the The inlet end of the piston container 3 for containing the foaming liquid, the piston container 4 for containing formation water, and the piston container 5 for containing crude oil are connected, and the outlet end of the piston container 3 for containing the foaming liquid is connected to the ...

example 2

[0053] Example 2 (optimization experiment of foam control injection parameters)

[0054] (1) Connect the experimental device: Connect the various components of the experimental device such as figure 1 Connect as shown, and check whether the airtightness of each pipeline and each valve is good, and whether the data acquisition system is working normally. The three-layer square core model with different permeability is fixed with a core holder. The size of the three-layer square core model with different permeability is 4.5cm×4.5cm×30cm. The three-layer core model is passed through conventional According to the rock gas permeability measurement method, the permeability of the three-layer core along the simulated liquid flow direction is 3012×10 -3 μm 2 , 986×10 -3 μm 2 and 153×10 -3 μm 2 , that is, the three-layer core model is used to simulate the heterogeneous reservoir conditions with high-permeability layers, medium-permeability layers and low-permeability layers respe...

example 3

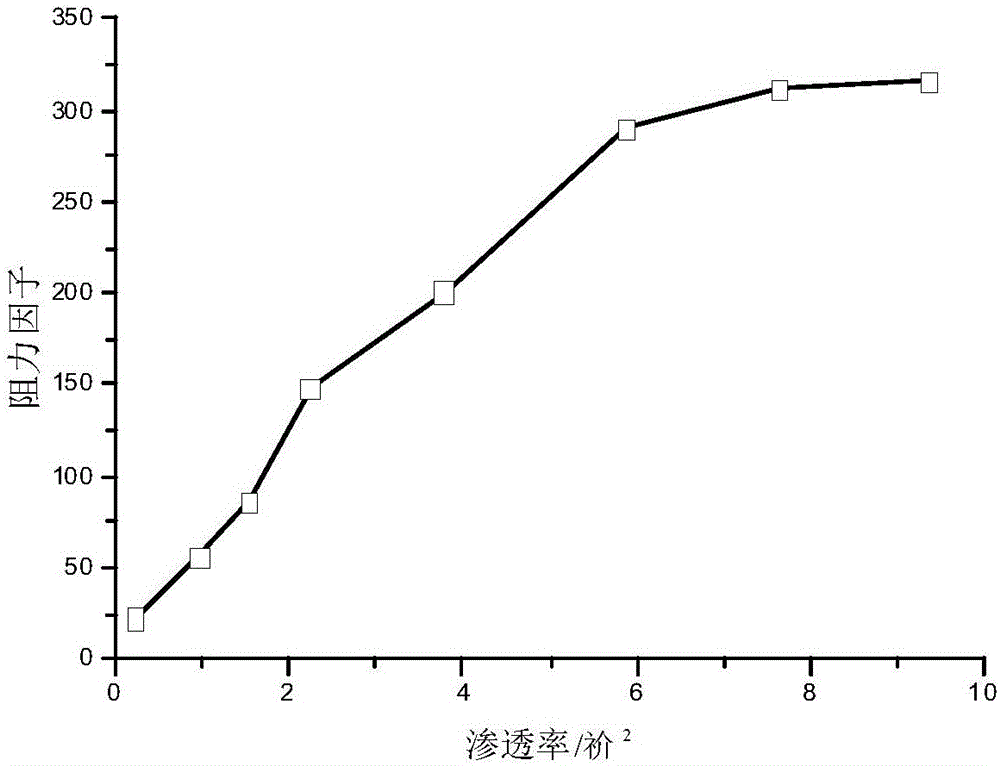

[0073] Example 3 (foam injection performance test)

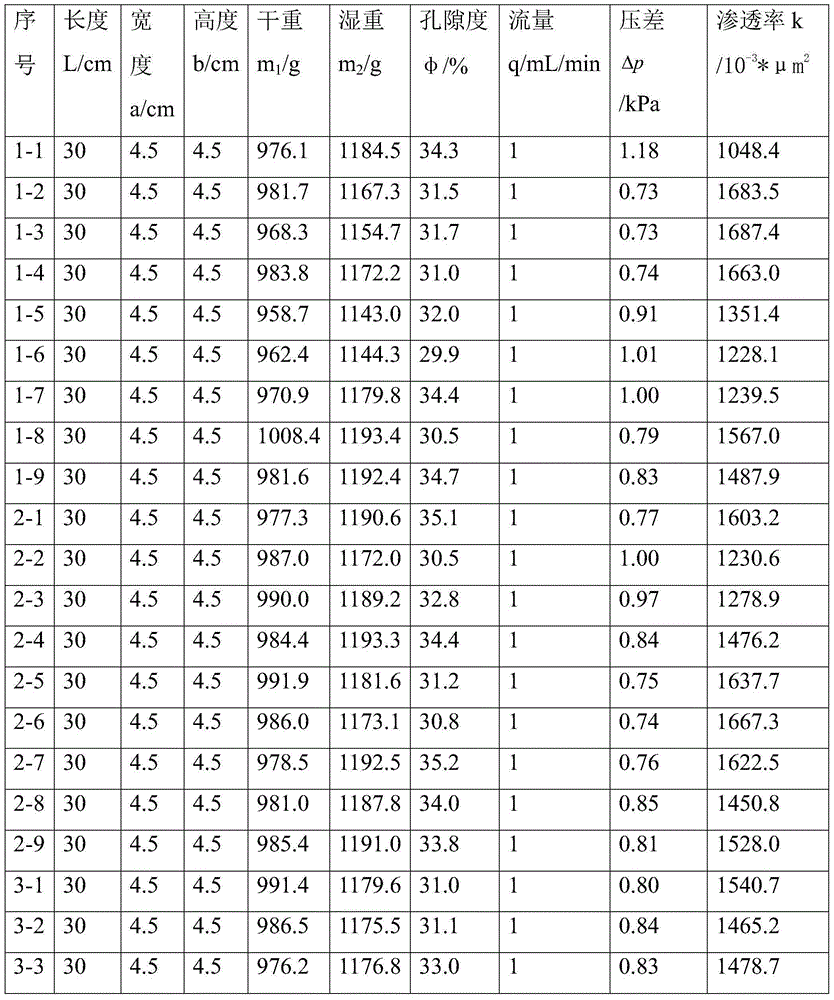

[0074] (1) Experimental device connection: according to the attached figure 1 Connect the experimental device, check the airtightness of pipelines and valves, check whether the data acquisition system is working normally, keep the valves closed, adjust the liquid level of the metering cylinder to 0, and select a single sand-filled pipe model with different permeability for the core model. See attached table 3 for the core parameters, and check the sealing state of the core model.

[0075] (2) Core model preprocessing:

[0076] (i) A single core model filled with 30-200 mesh quartz sand is used, and the dry weight is measured in m 1 , evacuate the sand-filled core model and keep it for 4-6 hours;

[0077] (ii) The core model is saturated with formation water: open the seventh valve, the ninth valve and the twelfth valve, open the fourth valve and start the plunger pump 22, inject formation water into the core model 13 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com