Ordered Cu-doped nano-porous tin oxide sensing device

A technology of tin oxide sensor and nanopore, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve problems such as potential safety hazards, flammable gases that are easy to detonate, and increased energy consumption, so as to avoid Destroy, enhance the effect of the breadth of work use and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

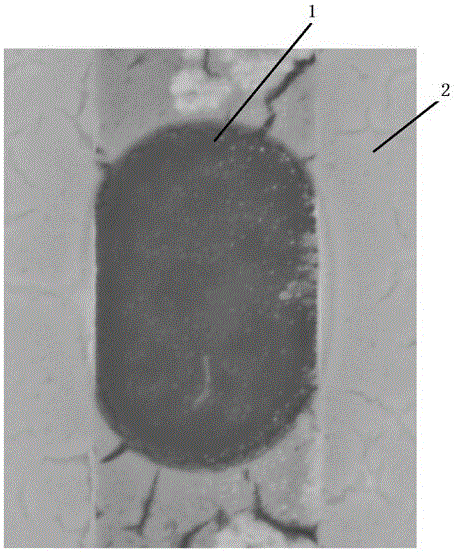

Image

Examples

Embodiment 1

[0025] 1. At room temperature, configure graphene oxide solution (solvent is deionized water) 1mg / ml, adjust the pH value to 9-10, start the homogenizer, take 100ul solution with a pipette, and control the speed of the homogenizer to 2000rpm , spin coating time is 30s.

[0026] 2. Dry the device (interdigitated gold electrode) coated with graphene oxide at 60°C. Weigh 0.04g of copper chloride and 1g of anhydrous tin tetrachloride, dissolve them in absolute ethanol, add 0.4g of surfactant F127, then add 1ml of concentrated hydrochloric acid, mix well to obtain a clear solution. Start the homogenizer, fix the graphene oxide-coated device in the chamber of the homogenizer, control the humidity of the chamber to 10%, spin-coat at a speed of 4000rpm, spin-coat for 30s, and repeat the spin-coating once. After drying the above-mentioned newly prepared sensor material device, put the device into a closed container, adjust the relative humidity in the container to 70%, and then put th...

Embodiment 2

[0033] 1. At room temperature, prepare a graphene oxide solution of 5 mg / ml, adjust the pH value to 9-10, start the homogenizer, take 100ul of the solution with a pipette, control the speed of the homogenizer to 2000rpm, and spin coating time to 45s.

[0034] 2. Dry the device coated with graphene oxide at 60°C. Weigh 0.08g of copper nitrate and 1.5g of tin tetranitrate, dissolve them in absolute ethanol, add 0.36g of surfactant P123, then add 1ml of concentrated hydrochloric acid, mix well to obtain a clear solution. Start the homogenizer, fix the graphene oxide-coated device in the chamber of the homogenizer, control the humidity of the chamber to 30%, spin-coating speed to 4000rpm, spin-coating time to 45s, and repeat the spin-coating 5 times. After drying the above-mentioned newly prepared sensor material device, put the device into a closed container, adjust the relative humidity in the container to 80%, and then put the container into a blast drying oven to adjust the te...

Embodiment 3

[0038]1. At room temperature, prepare a graphene oxide solution of 10mg / ml, adjust the pH value to 9-10, start the homogenizer, take 100ul solution with a pipette, control the speed of the homogenizer to 2000rpm, and spin coating time to 60s.

[0039] 2. Dry the device coated with graphene oxide at 60°C. Weigh 0.042g of copper sulfate and 1.3g of tin sulfate, dissolve them in absolute ethanol, add 0.36g of surfactant F127, then add 1ml of concentrated hydrochloric acid, mix well to obtain a clear solution. Start the homogenizer, fix the graphene oxide-coated device in the chamber of the homogenizer, control the humidity of the chamber to 50%, spin-coat at a speed of 4000rpm, spin-coat for 60s, and repeat the spin-coating 10 times. After drying the above-mentioned newly prepared sensing material device, put the device into an airtight container, adjust the relative humidity in the container to 95%, and then put the container into a blast drying oven to adjust the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com