Powder mass flow rate measuring device and method based on electrostatic and capacitive sensor arrays

A technology of electrostatic sensor and capacitive sensor, which is applied in mass flow measurement devices, indirect mass flow meters, etc., can solve the problems of particle concentration, uneven flow velocity distribution, large measurement error, unfavorable safe and efficient operation of industrial production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

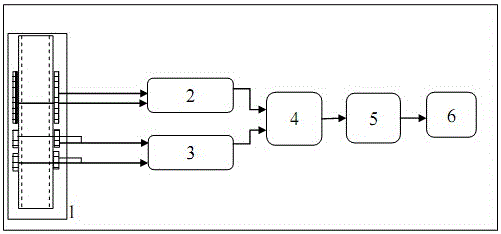

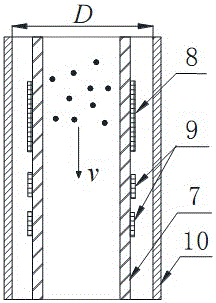

[0065] The working principle of the present invention is: according to the measured capacitance between the adjacent capacitor pole pieces of the capacitance sensor array, combined with the relationship between the output capacitance and the local concentration obtained through the experiment, the concentration distribution of the powder in the pipeline section is calculated. Using the electrostatic sensor array combined with the cross-correlation algorithm, the velocity distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com