Ceiling structure with double underneath type parallel radiant tubes and construction method of ceiling structure

A construction method and radiant tube technology, applied in building components, heating methods, building structures, etc., can solve the problems of inconvenient maintenance of radiant tube 2', large distance from radiation to the room, loss of radiant tube 2', etc., and achieve enhanced Energy utilization efficiency, uniform distribution, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

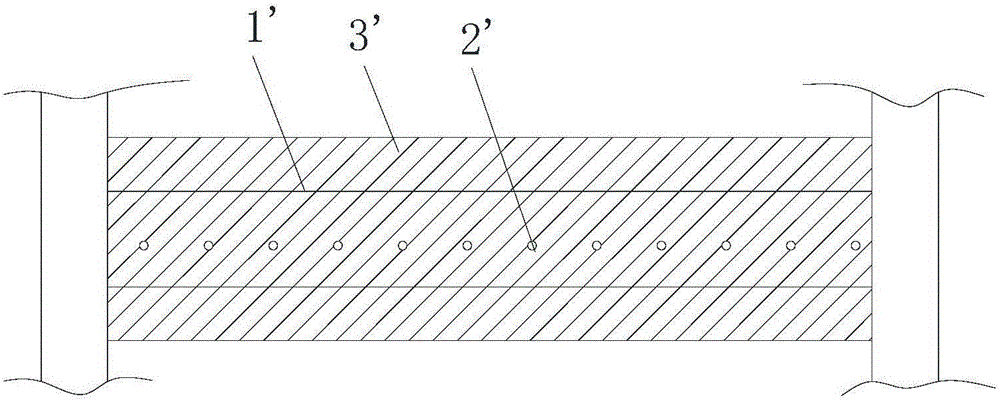

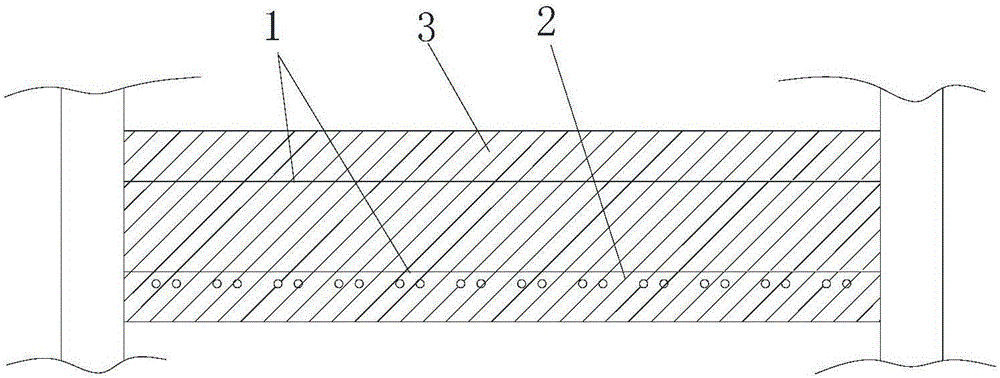

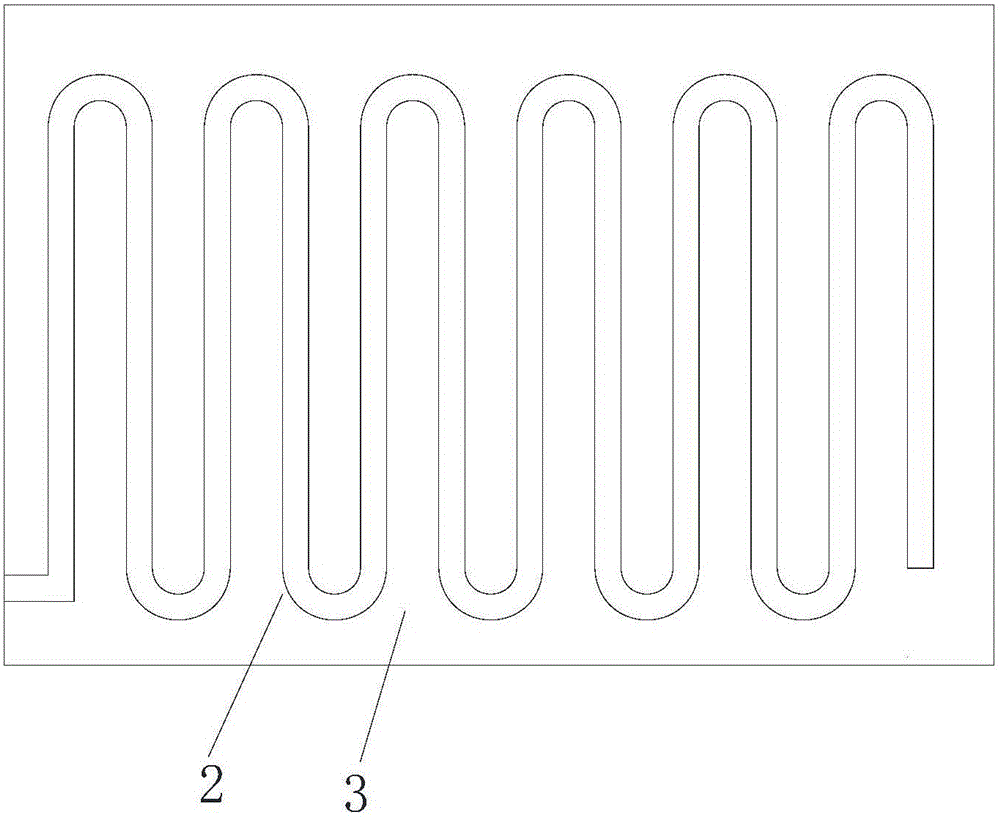

[0014] see figure 2 with image 3 As shown, according to the embodiment of the present invention, the double-parallel radiant tube under-mounted ceiling structure includes an integrally cast steel bar layer 1, radiant tube 2 and concrete layer 3, and the radiant tube 2 is located on the lower side of the steel bar layer 1, that is, close to the indoor On one side, the concrete layer 3 is covered outside the reinforcement layer 1 and the concrete layer 3, and the radiant tubes 2 are arranged in a double parallel structure.

[0015] In the double-parallel radiant tube under-mounted ceiling structure of the present invention, the radiant tube 2 is located on the lower side of the reinforcement layer 1, and is directly integrated with the concrete pouring in the process of forming the ceiling, which makes the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com