Control method of H2O (g) in sintering gas on high-proportion flue gas circulation condition

A technology of flue gas circulation and control method, which is applied in the direction of furnace components, energy efficiency improvement, process efficiency improvement, etc., and can solve problems such as slowing down of sintering speed, deterioration of sintering ore quality, reduction of sintering production efficiency and sintering ore quality, etc. Achieve the effect of reducing emissions, avoiding over-humidity, and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

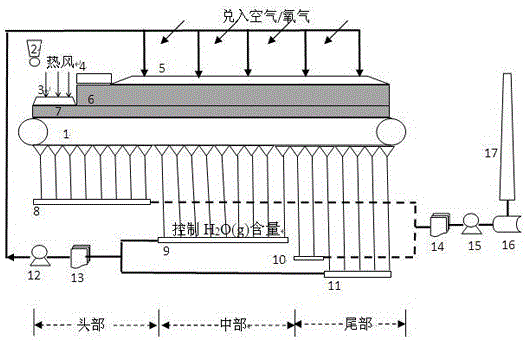

[0023] H in the sintering gas under the condition of a high proportion flue gas circulation of the present invention 2 The control method of O(g), its specific operation method is as follows:

[0024] The sintered material layer is divided into upper and lower layers by means of cloth (sintering raw material conditions: according to the mass ratio of mixed iron ore 61.22%, dolomite 5.01%, limestone 2.33%, quicklime 4.51%, sintered return ore 23.08%, coke powder 3.85% Ingredients (the main chemical components of the obtained sinter are: TFe57.7%, SiO 2 4.9%, R2.0, MgO1.8%)), the thickness of the lower material accounted for 20% of the thickness of the entire sintered material layer. Before the upper material is ignited, a sealed fume hood is added to introduce hot air to heat the lower material. The temperature of the hot air is 550°C. The length of the hot air hood accounts for 4% of the total length of the sintering machine. The method of high-proportion flue gas circulatio...

Embodiment 2

[0026] H in the sintering gas under the condition of a high proportion flue gas circulation of the present invention 2 The control method of O(g), its specific operation method is as follows:

[0027]The sintered material layer is divided into upper and lower layers by means of cloth (sintering raw material conditions: according to the mass ratio of mixed iron ore 61.41%, dolomite 5.61%, limestone 2.05%, quicklime 3.85%, sintered return ore 23.08%, coke powder 4.00% Ingredients (the main chemical composition of the obtained sinter is: TFe58.33%, SiO25.0%, R1.9, MgO2.3%)), the thickness of the lower layer of material accounts for 40% of the thickness of the entire sinter layer. Before the upper material is ignited, a sealed fume hood is added to introduce hot air to heat the lower material. The temperature of the hot air is 350°C. The length of the hot air hood accounts for 8% of the total length of the sintering machine. The method of high-proportion flue gas circulation is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com