Preparation method and system for green carbon containing biomass

A technology of biomass and biomass particles, applied in the field of clean energy, can solve the problems of low efficiency and achieve high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

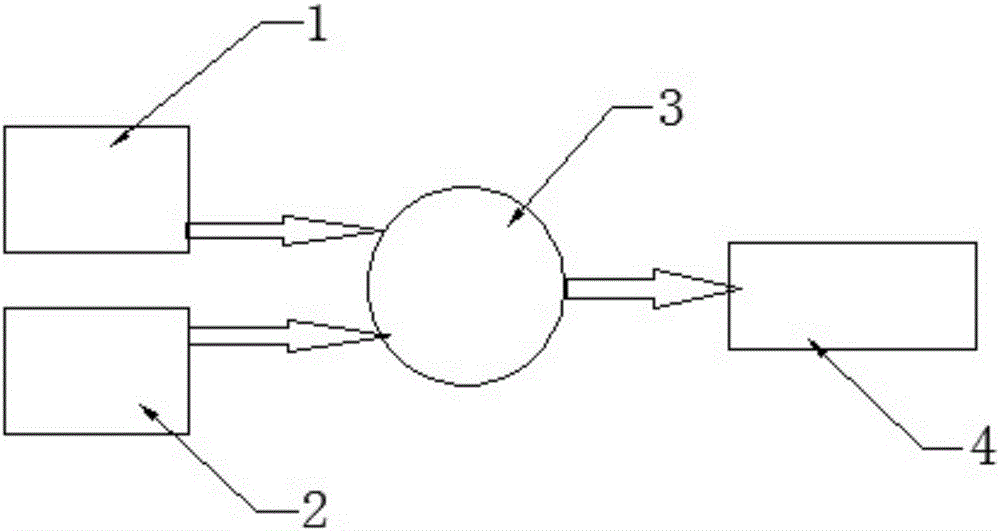

[0028] Such as figure 1 As shown, a system for preparing green carbon containing biomass includes: a biomass granulator, a coal granulator, a mixer, and a screw extruder. The biomass granulator is a mechanical device used to process biomass raw materials such as straws, grain husks, and bean husks into biomass granules. And the particle size of the required particles can be adjusted according to the demand. The coal pellet machine is a mechanical device used to process coke, semi-coke or machine-made charcoal into charcoal pellets. And the particle size of the required particles can be adjusted according to the demand. The screw extruder is a mechanical device used to process the mixture of charcoal particles, biomass particles, binder and water into green carbon rods. The main performance parameters of the screw extrusion molding machine are: the axial compression force is greater than 600kN, and the moving speed of the briquetting block is 1500-2500mm / min. The screw extr...

Embodiment 2

[0034] Utilize the method that the system described in embodiment one prepares the green charcoal that contains biomass, comprises the following steps:

[0035] (1) Processing one or more mixtures of coke, semi-coke or machine-made carbon into charcoal particles with a particle size of 15 mm; processing biomass materials into biomass particles with a particle size of 15 mm;

[0036] (2) After the charcoal granules, biomass granules, binder clay and water obtained in step (1) are fully mixed according to the mass ratio of 60:30:10:15, extruded and then dried to obtain the Biomass green carbon, after drying, the moisture of the green carbon is less than 2%.

[0037] In step (2), a screw extrusion molding machine is used to process the mixture of charcoal particles, biomass particles, binding agent, and water. The main performance parameters of the screw extrusion molding machine are: the axial compression force is 600kN, and the briquette The moving speed is 2500mm / min. The ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com