Red light-fluorescent light conversion material for plant lamp and preparation method of conversion material

A technology of conversion material and red light fluorescence, which is applied in the field of red light fluorescence conversion materials for plant lamps and its preparation, can solve the problem of low pigment absorption rate, and achieve the effect of convenient use and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

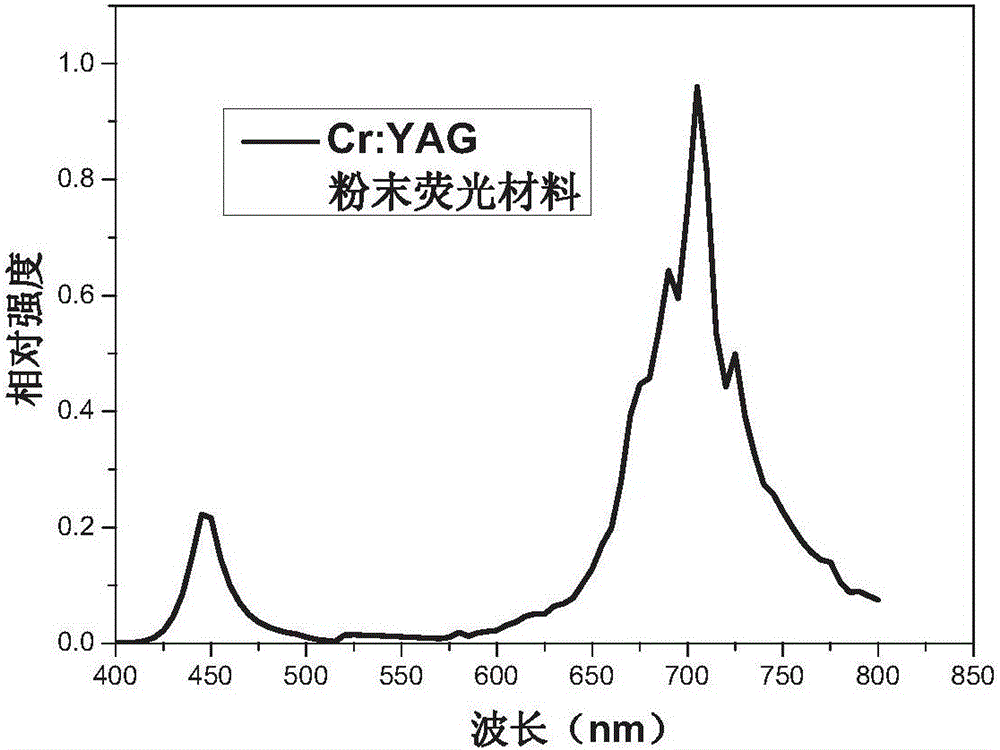

[0050] Embodiment 1: Cr: The preparation method of YAG powder conversion material

[0051] 1) Press Y 3 (Al 0.95 Cr 0.05 ) 5 o 12 Weigh each raw material, mix Cr:YAG powder conversion material, and add a small amount of BaF 2 As a flux, mix the raw materials evenly to obtain the mixed raw materials, and put them into the crucible;

[0052] 2) Burn the mixed raw materials at about 1600°C in an inert atmosphere for 5 hours, and then lower the temperature at a rate of 50°C per hour;

[0053] 3) Take out the powder, pulverize, wash and dry to obtain Cr:YAG powder conversion material, and then test the obtained YAG 3 (Al 0.95 Cr 0.05 ) 5 o 12 The spectrum of the powder sample under the excitation of blue light with a wavelength of 450 nm, the results are as follows figure 1 As shown in the figure, it can be seen from the figure that under the excitation of blue light, Cr:YAG powder has a strong broadband luminescence peak in the red light and near-infrared light bands of...

Embodiment 2

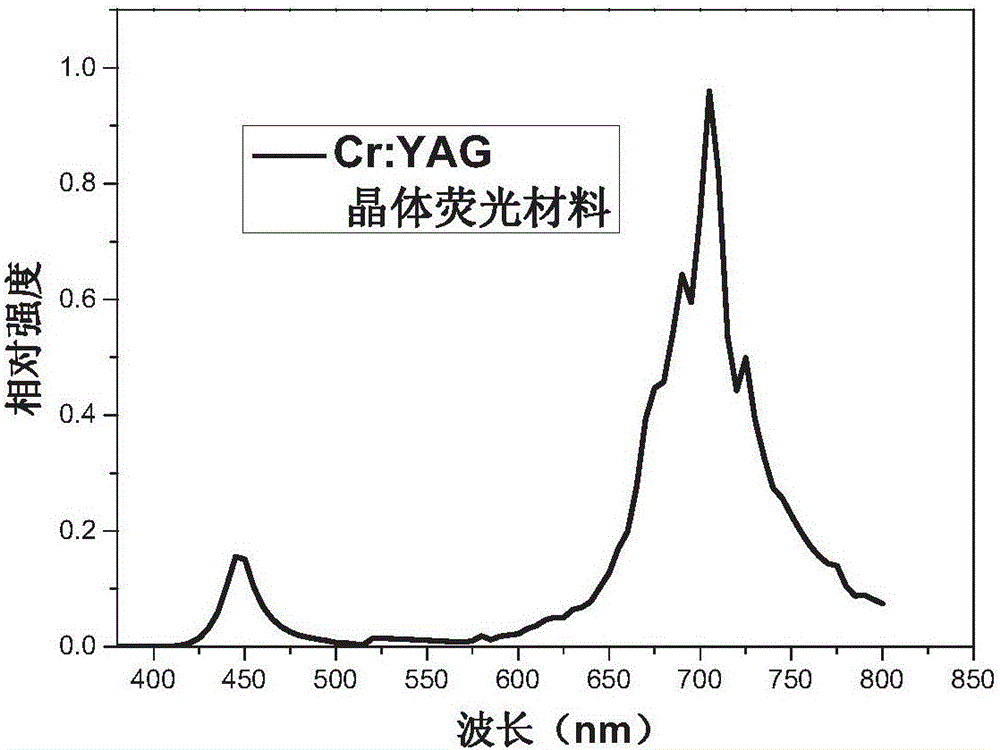

[0054] Embodiment 2: Cr: The preparation method of YAG crystal conversion material

[0055] 1) Press Y 3 (Al 0.98 Cr 0.02 ) 5 o 12 Weigh each raw material, mix Cr:YAG crystal powder, and then mix the weighed raw materials evenly to obtain mixed raw materials, and press them into cakes;

[0056]2) Fire the cake-shaped mixed raw materials at 1200°C under air for 20 hours;

[0057] 3) Finally, use the pulling method to heat to 1970°C in an inert atmosphere to melt the raw material, and then raise the temperature to 30°C on this basis, keep the melt at a constant temperature for 5 hours in an overheated state, and then start to grow, with a growth rate of 1.2mm / h , the speed is 10r / h.

[0058] 4) After the growth is completed, the temperature is lowered at a rate of 30° C. / h to obtain a crystal conversion material.

[0059] After the obtained crystal conversion material was cut, ground and polished, it was uniformly processed into a thickness of 0.3 mm, and then its lumines...

Embodiment 3

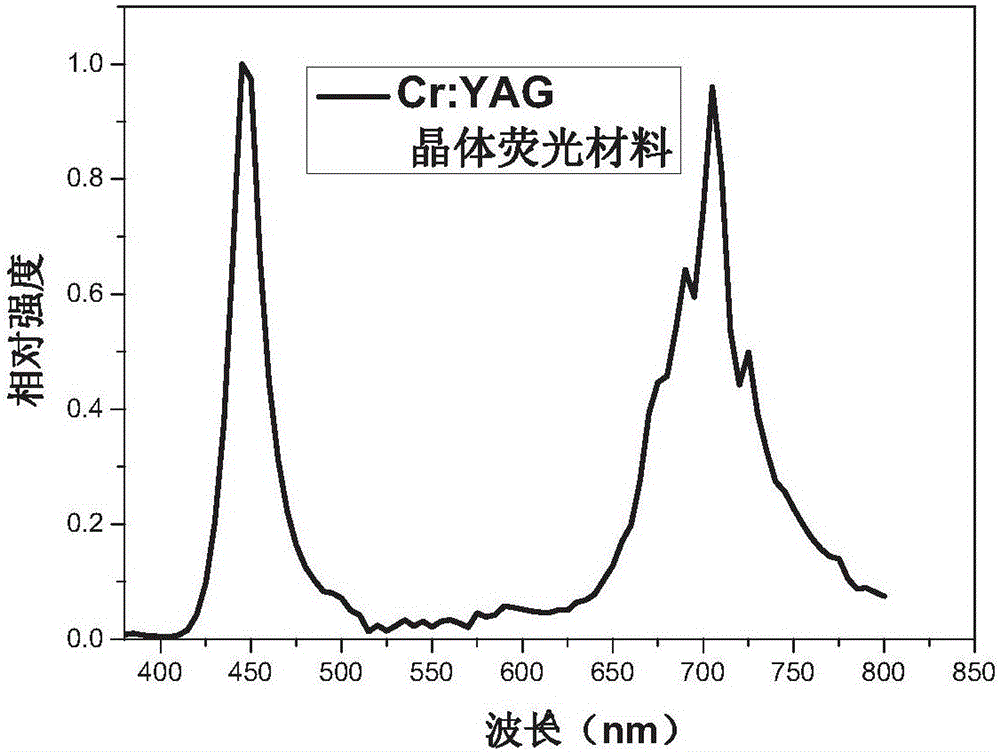

[0060] Embodiment 3: Cr: The preparation method of YAG crystal conversion material

[0061] 1) Press Y 3 (Al 0.999 Cr 0.001 ) 5 o 12 Weigh each raw material, mix Cr:YAG crystal powder, and then mix the weighed raw materials evenly to obtain mixed raw materials, and press them into cakes;

[0062] 2) Fire the cake-shaped mixed raw materials at 1300°C under air for 15 hours;

[0063] 3) Finally, use the pulling method to heat to 1970°C in an inert atmosphere to melt the raw material, and then raise the temperature to 30°C on this basis, keep the melt at a constant temperature for 5 hours in an overheated state, and then start to grow, with a growth rate of 0.8mm / h , the speed is 20r / h.

[0064] 4) After the growth is completed, the temperature is lowered at a rate of 40° C. / h to obtain a crystal conversion material.

[0065] After the obtained crystal conversion material was cut, ground and polished, it was uniformly processed into a thickness of 0.3 mm, and then its lumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com