Low-TVOC thermoplastic elastomer composition for automotive interior trim and preparation method of low-TVOC thermoplastic elastomer composition

A technology for thermoplastic elastomers and automotive interiors, applied in the field of thermoplastic elastomer compositions and their preparation, can solve problems such as difficult detection, inability to enter automotive interior parts, failure to meet use requirements, etc., achieve low specific gravity and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

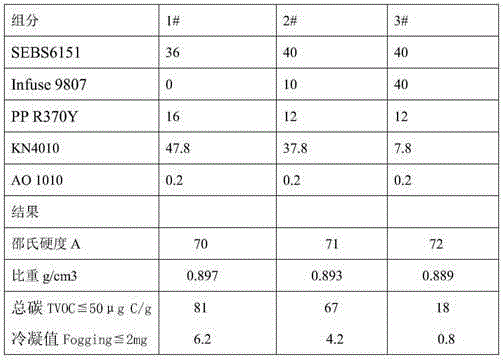

Examples

Embodiment 1~4

[0027] In Examples 1 to 4, the olefin block copolymer was produced by the Dow Chemical Company under the trade name of Infuse9807; the styrene-ethylene-butylene-styrene block copolymer was produced by the US Keteng Company under the trade name of G1651. Styrene-ethylene-butylene-styrene block copolymer; homo-polypropylene is homo-PP produced by SK Petrochemical Company in South Korea, the trade name is PPR370Y; naphthenic oil is naphthenic oil produced in Xinjiang Karamay, the trade name It is KN4010; the antioxidant is a hindered phenolic antioxidant, specifically AO1010 of Ciba Company.

Embodiment 1

[0029] The raw materials used include styrene-ethylene-butene-styrene block copolymer (SEBS6151) 35kg, naphthenic oil (KN4010) 9.9kg, olefin block copolymer (Infuse9807) 40kg, homopolypropylene (PPR370Y) 15kg , Antioxidant (AO1010) 0.1kg.

[0030] The preparation method is as follows:

[0031] (1) Weigh the raw materials according to the components and their weight percentages shown in Table 1;

[0032] (2) Mix the SEBS and naphthenic oil (plasticizer) in the above raw materials in a high-mixer for 20-30 minutes;

[0033] (3) Add other raw materials, mix well, and take out;

[0034] (4) Then put it into a twin-screw machine for extruding and granulating. The screw's main engine speed is 200-300 rpm, and the processing temperature is 180-210°C.

Embodiment 2

[0036] The raw materials used include styrene-ethylene-butene-styrene block copolymer (SEBS6151) 30kg, naphthenic oil (KN4010) 14.8kg, olefin block copolymer (Infuse9807) 45kg, homopolypropylene (PPR370Y) 10kg , Antioxidant (AO1010) 0.2kg.

[0037] The preparation method is as follows:

[0038] (1) Weigh the raw materials according to the components and their weight percentages shown in Table 1;

[0039] (2) Mix the SEBS and naphthenic oil (plasticizer) in the above raw materials in a high-mixer for 20-30 minutes;

[0040] (3) Add other raw materials, mix well, and take out;

[0041] (4) Then put it into a twin-screw machine for extruding and granulating. The screw's main engine speed is 200-300 rpm, and the processing temperature is 180-210°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com