2, 4-diaminotoluene purification system

A diaminotoluene and crystallizer technology, which is applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of secondary pollution, cannot meet the needs of industrial production, and the yield of molecular sieve method is small, so as to achieve convenient purification and compact structure , the overall effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

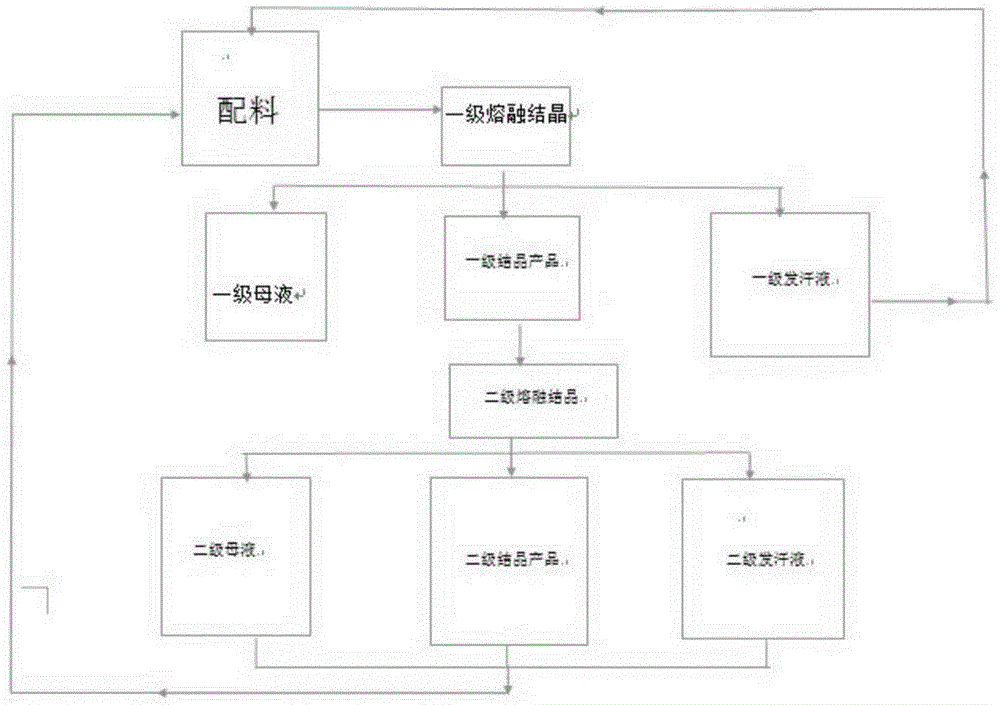

Image

Examples

example 1

[0063] Melt 500kg of 2,4 and 2,6-diaminotoluene mixture (isomerization ratio: 2,4:2,6=80:20) at a temperature of 90°C and pump it into a crystallizer that is also preheated at 90°C Medium; adjust the temperature of the circulating water in the thermostat sleeve, slowly reduce (cooling rate 2°C / h) the temperature of the crystallizer to 65°C, and keep the temperature at this temperature for half an hour, then release the raffinate; adjust the temperature in the thermostat sleeve The circulating water temperature rises slowly (heating rate 4°C / h), and then keeps the temperature for half an hour after reaching 86°C. The sweating liquid collected during the heating process is stored separately from the residual liquid; raise the temperature of the crystallizer to 100°C to melt all the internal materials After that, release the product. 250 kg of a mixture of 2,4-diaminotoluene and 2,6-diaminotoluene (isomerization ratio 95:5) was obtained.

Embodiment 2

[0065] Melt 250kg of the product in Example 1 at a temperature of 100°C, and pump it into a crystallizer at 95°C; adjust the temperature of the circulating water in the thermostat sleeve, and slowly reduce the temperature of the crystallizer (1.5°C / h) to 75°C, And keep the temperature at this temperature for half an hour, then release the residual liquid; adjust the temperature of the circulating water in the thermostat sleeve to increase slowly (2°C / h), and keep the temperature at 98°C for half an hour. Store the residual liquid separately; raise the temperature of the crystallizer to 100°C to melt all the internal materials, and release the product. 200 kg of 2,4-diaminotoluene was obtained, and the purity (GC method) of the product was 99.1%.

Embodiment 3

[0067] Mix 400kg of 2,4 and 2,6-diaminotoluene mixture (isomer ratio: 2,4:2,6=80:20) with 100kg of sweating liquid in Example 1, melt at a temperature of 90°C, Pump into the crystallizer at 90°C; adjust the temperature of the circulating water in the thermostat sleeve, slowly lower the temperature of the crystallizer (1.5°C / h) to 75°C, and keep the temperature at this temperature for half an hour to release the raffinate; Adjust the temperature of the circulating water in the thermostat sleeve to increase slowly (2°C / h), keep the temperature at 98°C for half an hour, store the sweating liquid collected during the temperature rise and the residual liquid separately; raise the temperature of the crystallizer to 100°C, so that After all the internal materials are melted, the product is released. 280 kg of a mixture of 2,4-diaminotoluene and 2,6-diaminotoluene (isomerization ratio 95:5) was obtained.

[0068] In a word, the present invention also has the following advantages at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com