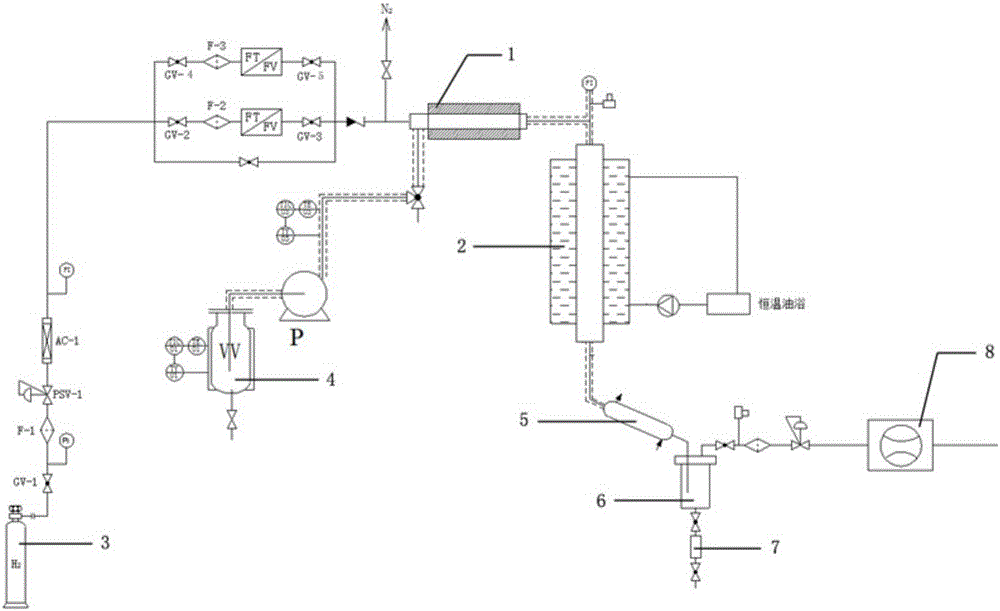

Continuous hydrogenation reaction system for liquid organic hydrogen storage carrier and hydrogenation reaction method

A technology of hydrogenation reaction and hydrogen storage carrier, which is applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of interruption of dehydrogenation reaction and high hydrogen storage system, so as to improve hydrogenation efficiency, improve reaction effect, improve The effect of the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: When 140mL of catalyst is filled in a single-tubular fixed-bed reactor, the space velocity is 0.3, the gas-liquid volume ratio is 2000, the infusion pump flow rate is 0.7mL / min, the hydrogen flow rate is 1.4L / min, and the kettle pressure is 7MPa. The reacted product is shown in Table 1 (mole percent).

[0057] Table 1

[0058] A12 / %

Embodiment 2

[0059] Example 2: When 70 mL of catalyst is filled in a single-tubular fixed-bed reactor, the space velocity is 0.5, the gas-liquid volume ratio is 2000, the infusion pump flow rate is 0.58 mL / min, the hydrogen flow rate is 1.16 L / min, and the kettle pressure is 7 MPa. The products after the reaction are shown in Table 2 (mole percent).

[0060] Table 2

[0061] A12 / %

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com