CNC linkage integrated equipment

A technology of equipment and machine tools, which is applied in the field of CNC linkage integrated equipment, can solve problems such as unfavorable industrial production, cumbersome process, and poor stability, and achieve the effects of improving processing efficiency, saving costs, and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

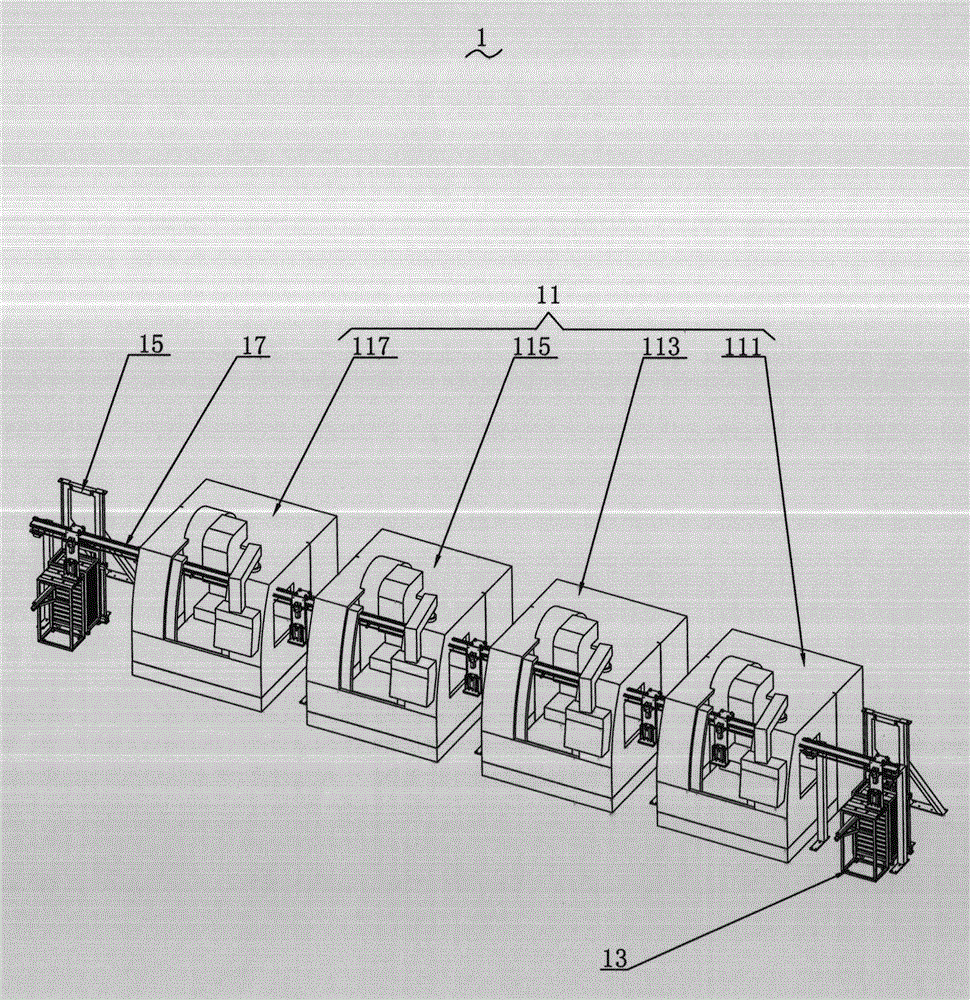

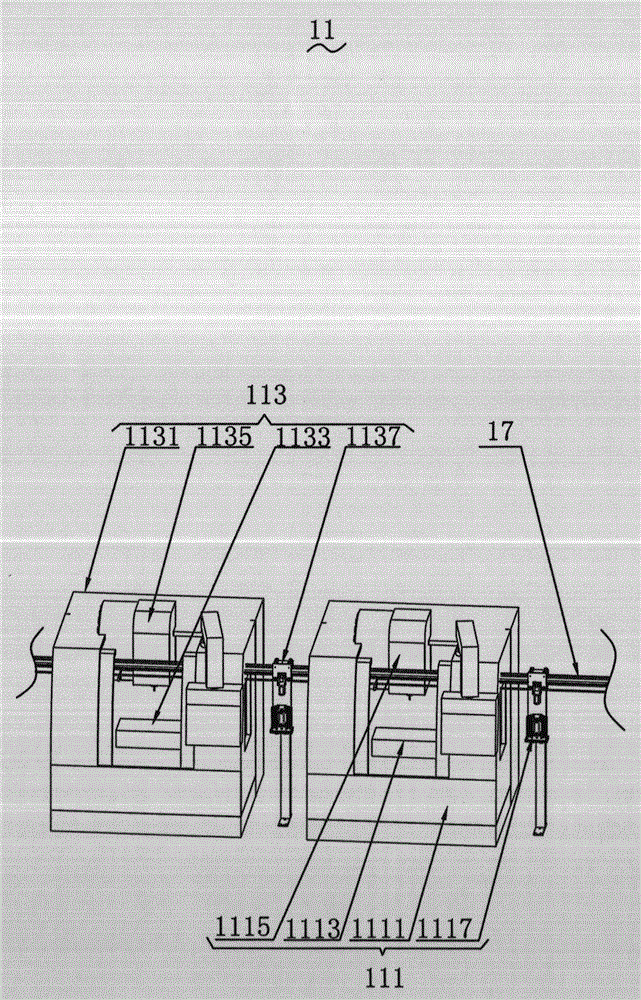

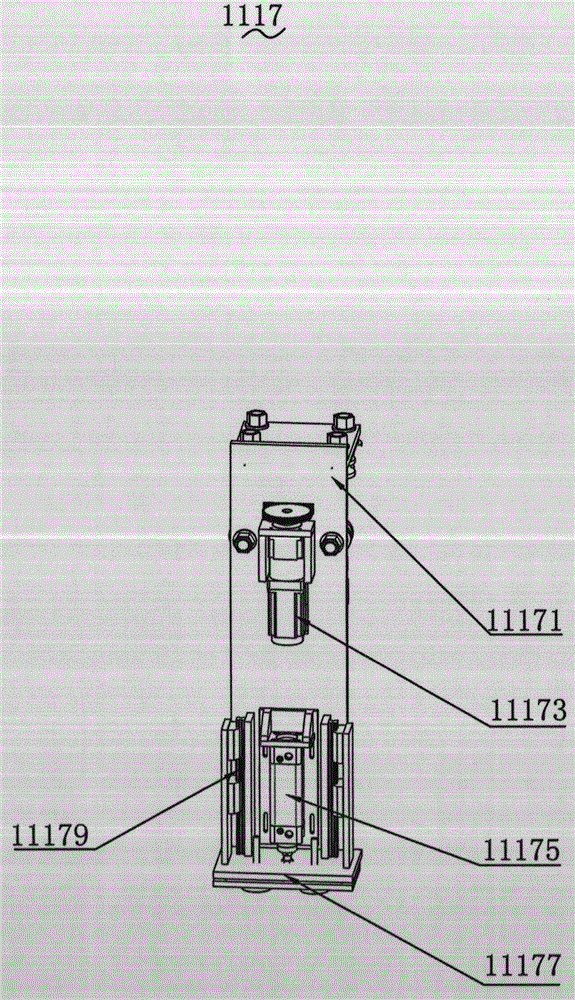

[0027] see figure 1 , CNC linkage integrated equipment 1 of the present invention comprises a feeding device 13, a material receiving device 15, a manipulator rail 17 and a machine tool system 11, the machine tool system 11 is located between the feeding device 13 and the material receiving device 15, and the machine tool system 11 includes No. 1 machine tool 111, No. 2 machine tool 113, No. 3 machine tool 115, and a high-precision machine 117 are evenly arranged side by side. The manipulator track 17 runs through the machine tool system 11, and the two ends are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com