Powder-spraying and paint-spraying single-line spray system and process

A technology of powder spraying and collinearity, which is applied in the direction of spraying booths, coatings, spraying devices, etc., can solve the problems of not being able to spray powder lines, long color change time, and affecting production tempo, so as to reduce investment costs, improve production tempo, Improve the effect of spraying quality and production beat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

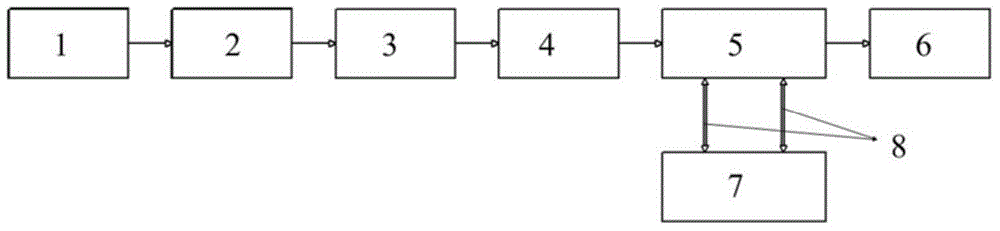

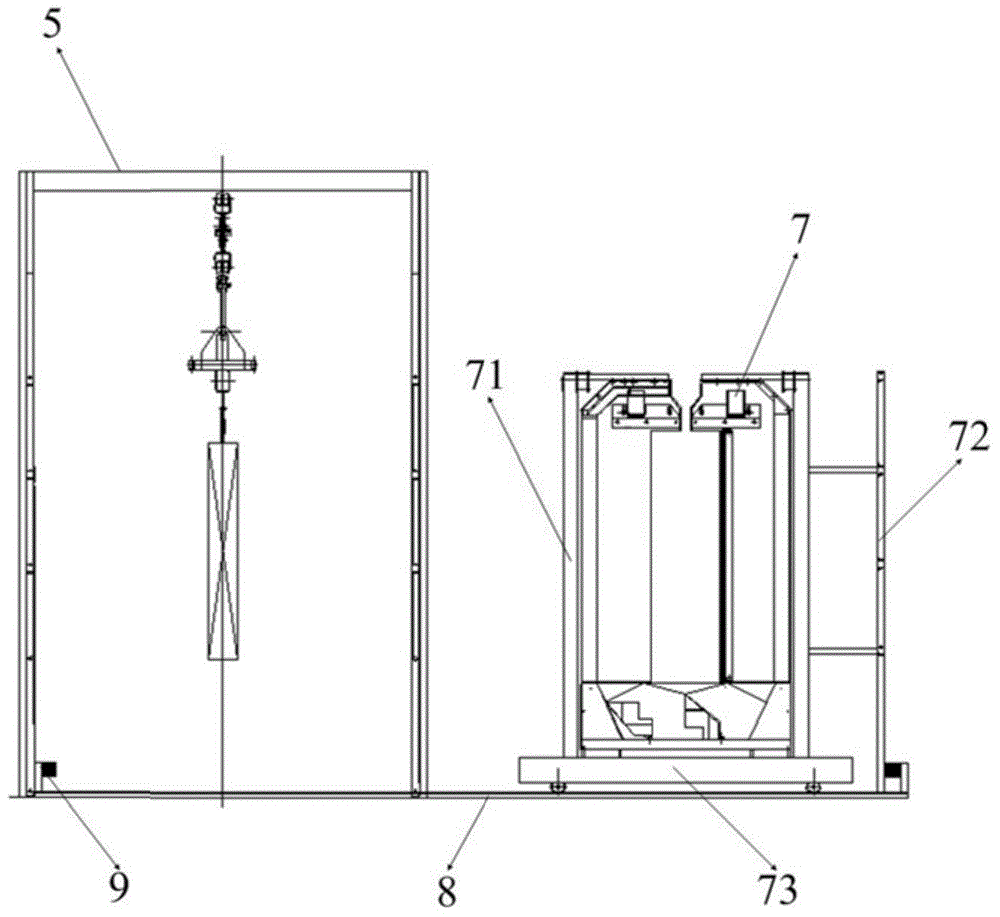

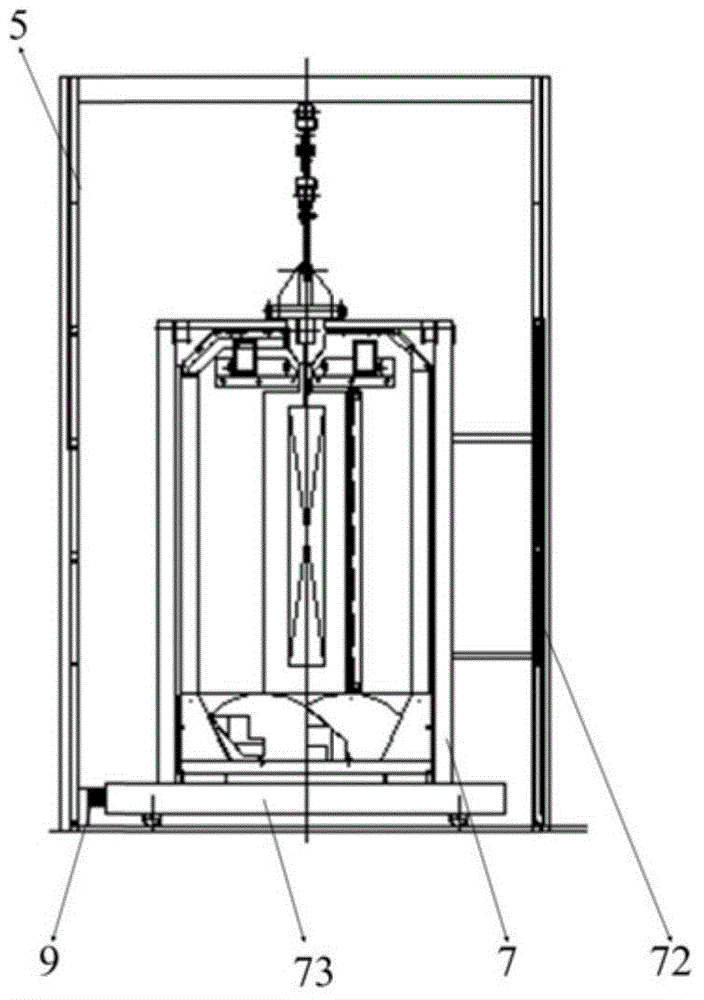

[0041] refer to figure 1 , the co-linear spraying system of powder spraying and spray paint provided by the embodiment of the present invention includes a glue coating room 1, a color spraying paint room 2, a leveling room 3, a varnish spraying room 4, a leveling room 5 and a drying room arranged in sequence 6. It also includes a mobile powder room 7; the second leveling chamber 5 is provided with an opening for the entry and exit of the mobile powder room 7, and the opening corresponds to an opening and closing device.

[0042] The main line in this system is the paint spraying line. When spraying paint, the mobile powder room 7 is located outside the second leveling chamber 5, and the opening is closed, so that the second leveling chamber 5 is a closed space,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com