Preparation method for nafcillin molecular imprinting adsorbent

A technology of nafcillin and molecular imprinting, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of poor thermal stability and easy decomposition of β-lactam rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

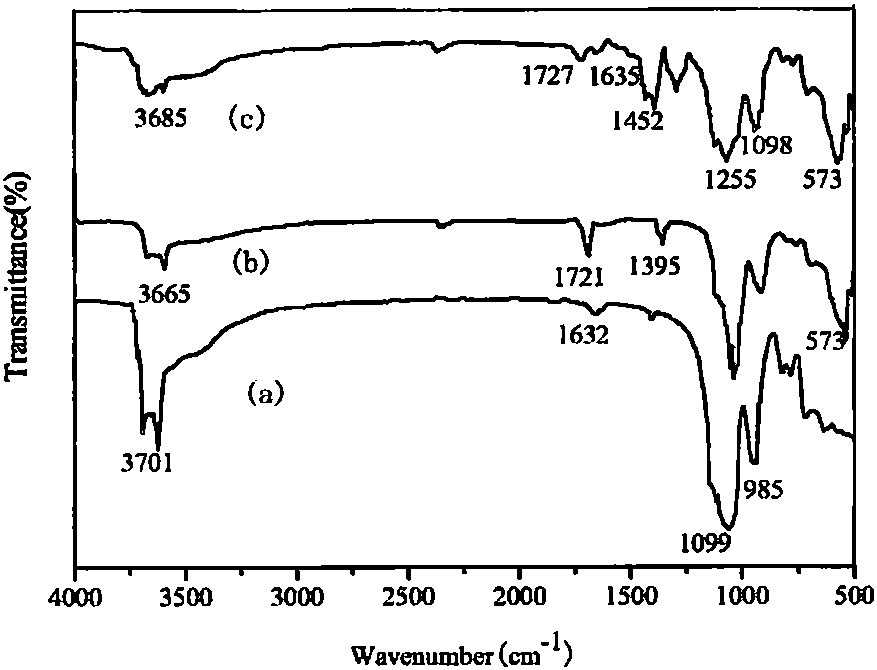

[0023] (1) Activation of illite and vinyl functionalization

[0024] The massive illite is ground by a ball mill, passed through a 100-mesh sieve, calcined at 180°C for 24 hours, and then heated in 3.0mol / L HNO 3 The solution was refluxed at 80°C for 12.0h, the product was washed with distilled water until neutral, and dried at 120°C to obtain acid-activated illite.

[0025] According to the consumption ratio of acid activated illite, 3-(methacryloyloxy)propyltrimethoxysilane and toluene, acid activated illite: 3-(methacryloyloxy)propyltrimethoxysilane: toluene mass The ratio is 1.0:3.0:100 (g / g / g). Add the mixed solution into a three-necked flask, disperse it evenly by ultrasonic, put it in an oil bath at 90°C, and stir it vigorously for 24 hours. After the reaction is completed, cool it to room temperature. After washing with acetone, methanol and deionized water several times, and vacuum drying at 60°C, the vinyl-functionalized illite, illite-MPS, was obtained.

[0026] (2)...

Embodiment 2

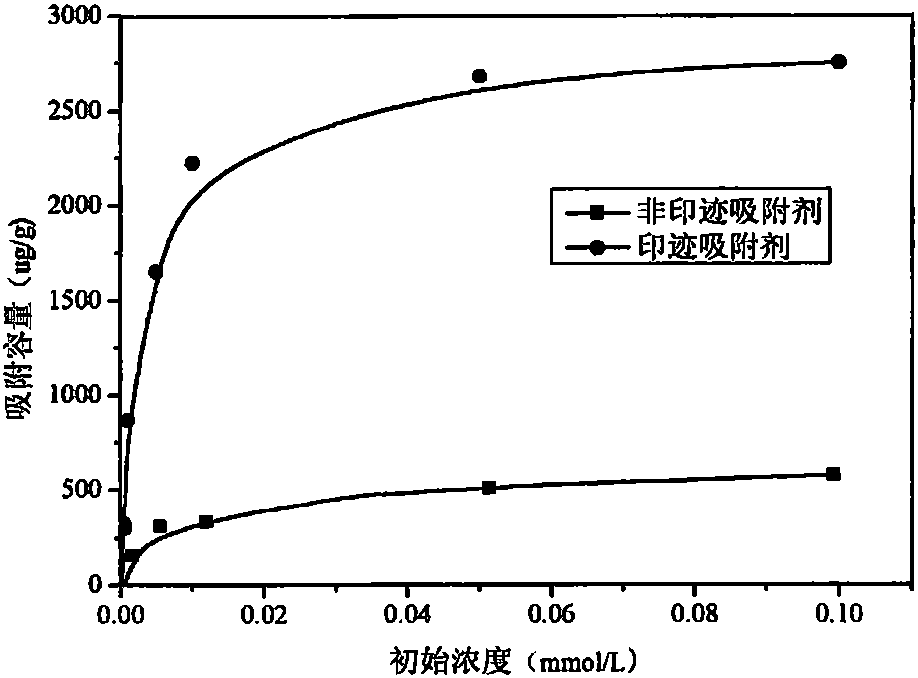

[0034] Take 10 mL of nafcillin solution with an initial concentration of 0.0005 mmol / L to 0.1 mmol / L and add it to a centrifuge tube, add 5.0 mg of nafcillin molecularly imprinted adsorbent and non-imprinted adsorbent respectively, and place the test solution in a 25°C water bath Leave standstill in the pot for 24h, utilize the ultraviolet-visible spectrophotometer to measure the concentration of nafcillin in the solution after adsorption, calculate the adsorption capacity, figure 2 The results show that the saturated adsorption capacity of nafcillin by molecularly imprinted adsorbent and non-imprinted adsorbent is 2750 μg / g and 512 μg / g, respectively, indicating that molecularly imprinted adsorbent has larger adsorption capacity than non-imprinted adsorbent, It indicated that more specific binding sites were formed on the surface of nafcillin molecularly imprinted adsorbent during the imprinting process.

Embodiment 3

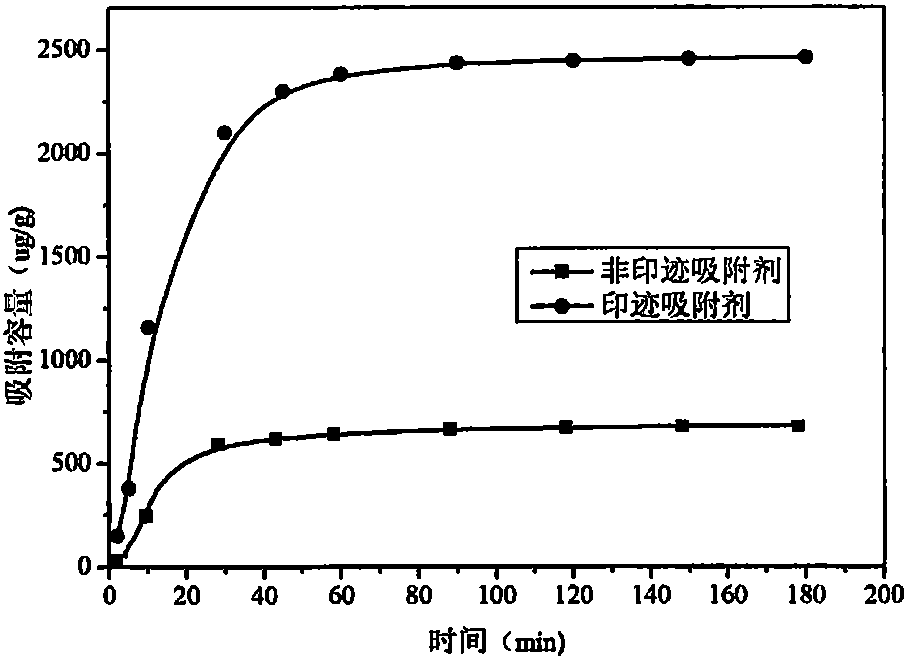

[0036] Take 10 mL of nafcillin solution with an initial concentration of 0.05 mmol / L and add it to a centrifuge tube, add 5.0 mg of nafcillin molecularly imprinted adsorbent and non-imprinted adsorbent, and place the test solution in a water bath at 25°C for 2 . image 3 It can be seen that, at the beginning, with the increase of adsorption time, the adsorption capacity increased rapidly, and the adsorption reached equilibrium after 60 min. In the whole range of adsorption time, the adsorption capacity of nafcillin molecularly imprinted adsorbent to nafcillin was greater than that of non-imprinted adsorbent to The adsorption capacity of nafcillin, the results showed that the imprinted sorbent exhibited higher adsorption capacity and faster mass transfer than the non-imprinted sorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com