Preparation method for polyvinyl alcohol/attapulgite-polyion liquid catalytic esterification composite membrane

A technology of polyionic liquid and polymeric ionic liquid, which is applied in the field of membrane materials, can solve the problems of being easily corroded by alcohol, reducing the swelling of the membrane to oil and methanol, and being easily damaged, and achieves the effect of low price and reduced material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

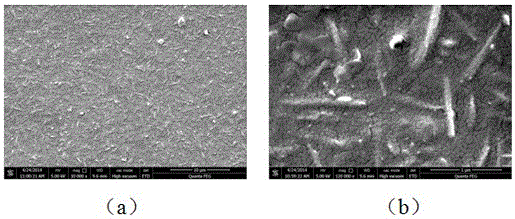

Image

Examples

Embodiment 1

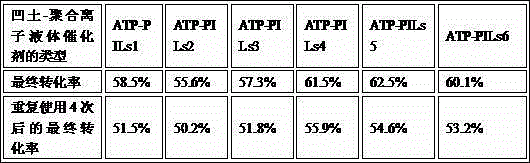

[0025] Example 1: Add 1 g of attapulgite-polymeric ionic liquid catalyst (ATP-PILs) to 99 mL of distilled water, stir at room temperature for 2 h to prepare a 1 wt.% ATP-PILs1 suspension; put 5 g of PVA into a beaker filled with 95 mL of deionized water, and use Stir the glass rod for 10 minutes, seal it, stir at 80°C for 2.5 hours, then cool to room temperature, vacuum defoam for 4 hours, and make a 7wt.% PVA solution; each take 25mL of ATP-PILs1 suspension and PVA solution and mix them at 1:1, seal , stirring at room temperature for 2 hours at 1200r / min, ultrasonic degassing for 30 minutes, vacuum degassing for 4 hours, and standing for 24 hours to obtain the casting solution; scrape the casting solution on a smooth and clean glass plate to form a wet film of a certain thickness, and then Dry at room temperature in an ultra-clean bench for 24 hours, then peel off the dry film from the glass plate and sandwich it between two glass plates covered with non-woven fabrics, place...

Embodiment 2

[0028] Example 2: The difference from Example 1 is that ATP-PILs1 is selected as the model catalyst, and 100g of ATP-PILs1 suspension with a mass fraction of 1wt.%-10wt.% is configured. Other preparation and analysis methods are the same as in Example 1. The prepared composite membrane catalyzes The performance is as follows:

[0029] Mass fraction of ATP-PILs1 suspension 1% 5% 10% final conversion rate 58.5% 90.1% 91.8% The final conversion rate after repeating 4 times 51.5% 87.6% 85.8%

Embodiment 3

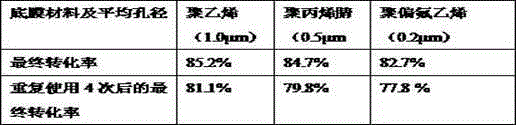

[0030] Example 3: Take 5g of ATP-PILs1 and add it to 95mL of distilled water, stir at room temperature for 2h to prepare a 5wt.% ATP-PILs1 suspension; put PVA into a beaker filled with deionized water, stir with a glass rod for 10 minutes, and seal it with a glass rod at 80°C Stir at constant temperature for 2.5 hours, then cool to room temperature, vacuum defoam for 4 hours, and make 100g of 5wt.%-10wt.% PVA solution; each take 25mL of ATP-PILs1 suspension and PVA solution and mix at 1:1, seal, and stir at room temperature at 1200r / min After 2 hours, ultrasonic degassing for 30 minutes, and then vacuum degassing for 4 hours, then let it stand for 24 hours to obtain the casting solution; scrape the casting solution on a smooth and clean glass plate to form a wet film of a certain thickness, and then place it in the ultra-clean bench at room temperature Dry for 24 hours, then remove the dry film from the glass plate and sandwich it between two glass plates covered with non-wov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com