Sandwich structured composite proton exchange membrane, and preparation method and use thereof

A proton exchange membrane, sandwich technology, applied in structural parts, electrical components, circuits, etc., can solve problems such as increasing the proportion of sulfonated GO, hindering proton diffusion, and becoming brittle in composite membranes, achieving low cost, reduced penetration, and thermal stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments and technical effects of the present invention will be more fully described below in conjunction with specific examples and related drawings.

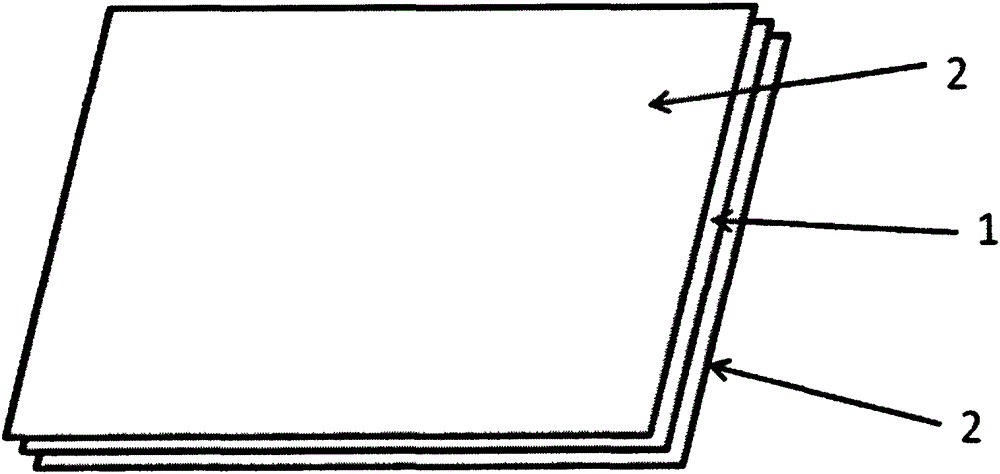

[0029] The present invention is a composite proton exchange membrane with a sandwich structure, and its structure is schematically shown as figure 1 As shown, it includes a base film 1 superimposed on each other and an outer film 2 distributed on both sides of the base film 1. The base film 1 is a self-supporting sulfonated surface with holes in graphene oxide paper, and the outer film 2 is a sulfonated polyether ether. The ketone polymer layer, the outer membrane 2 and the base membrane 1 are connected to each other through hydrogen bonds. Among them, the thickness of the sandwich structure composite proton exchange membrane is preferably 50-110 μm; the thickness of the base membrane 1 is 30-90 μm; the thickness of the outer membrane 2 is 5-30 μm.

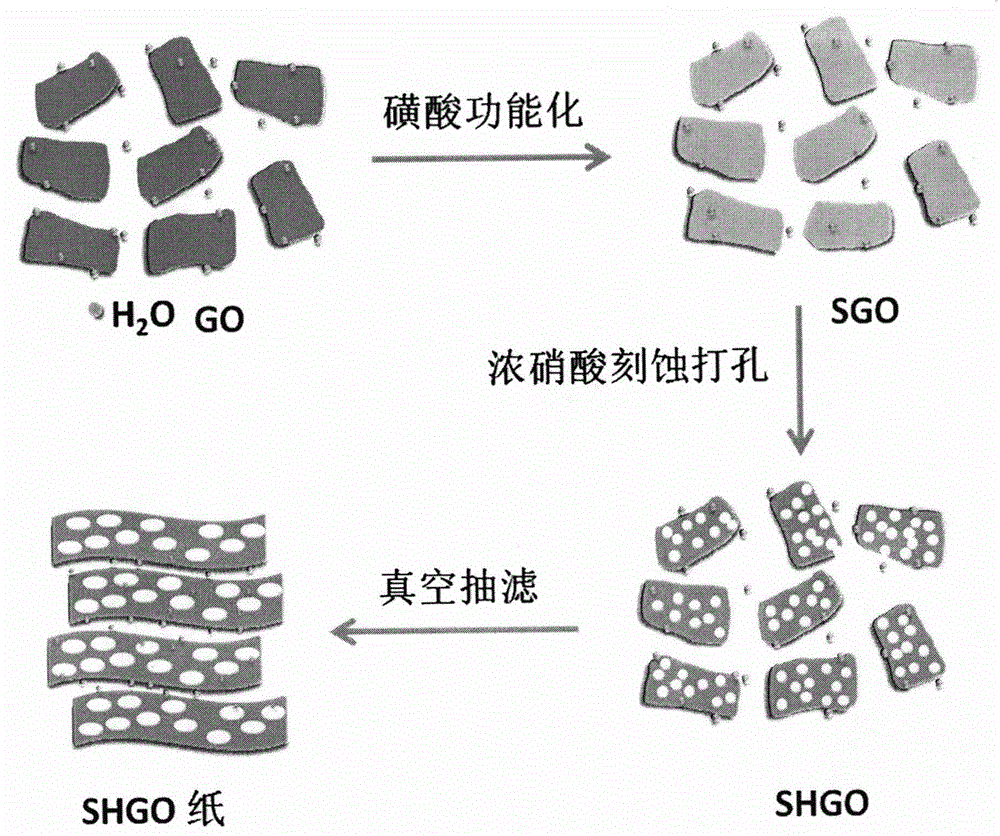

[0030] The preparation of the sandwich structure composite pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ion exchange capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com