Automatic stamp-pad ink device for button cell

A button battery and driving device technology, which is applied in the manufacture of primary batteries, secondary batteries, and battery pack components, etc., can solve the problems of easy drop of button batteries, poor printing ink quality, and low work efficiency, so as to improve production efficiency, The effect of improving printing ink quality and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

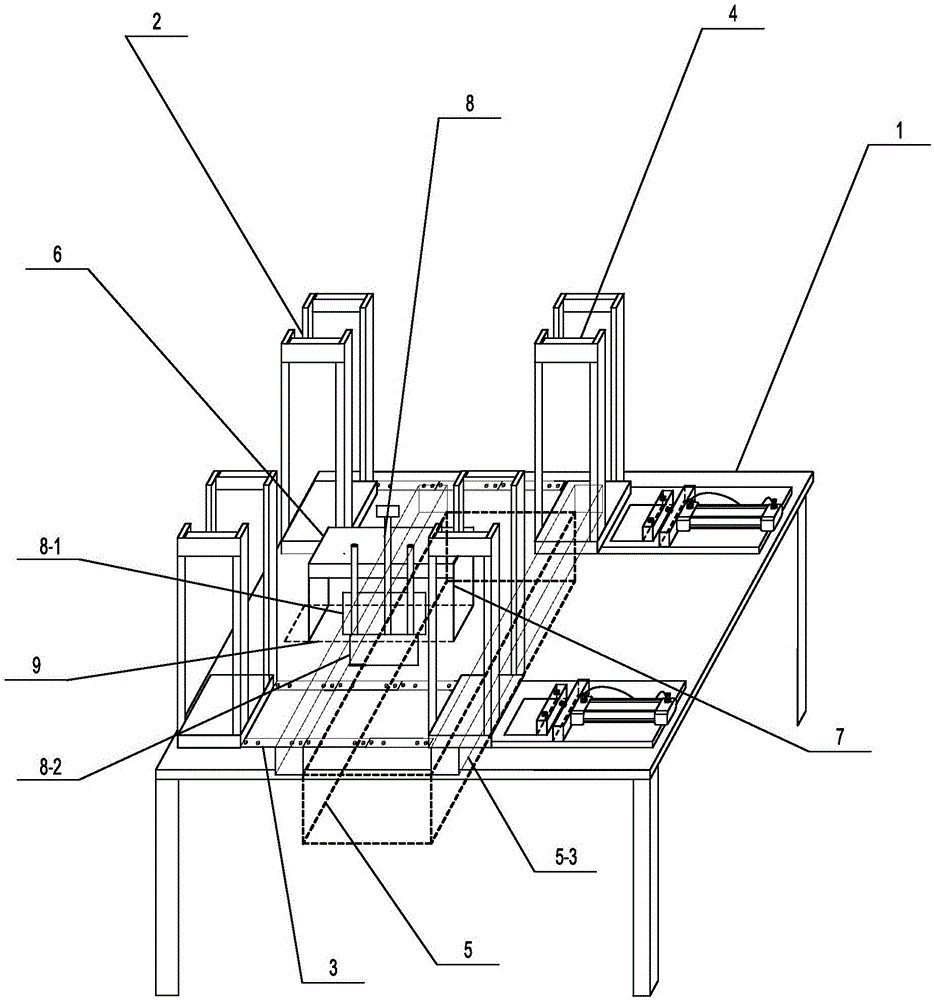

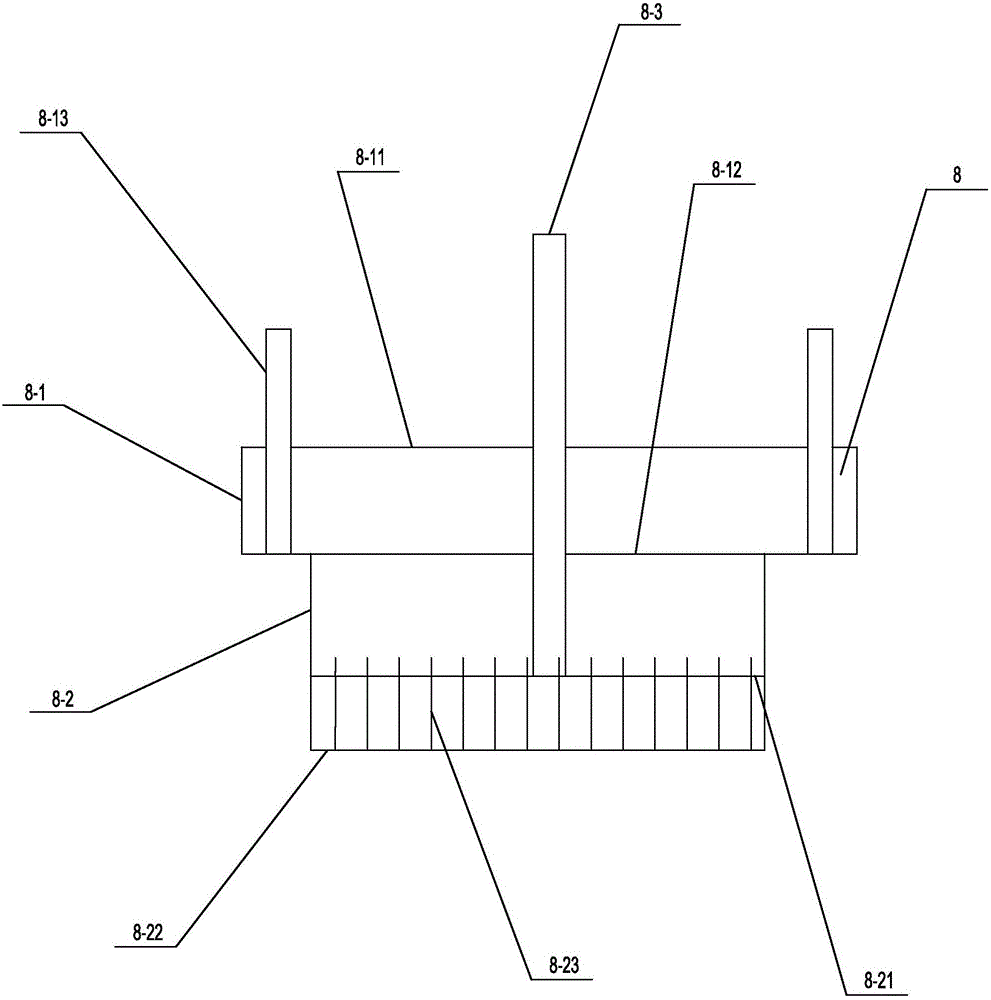

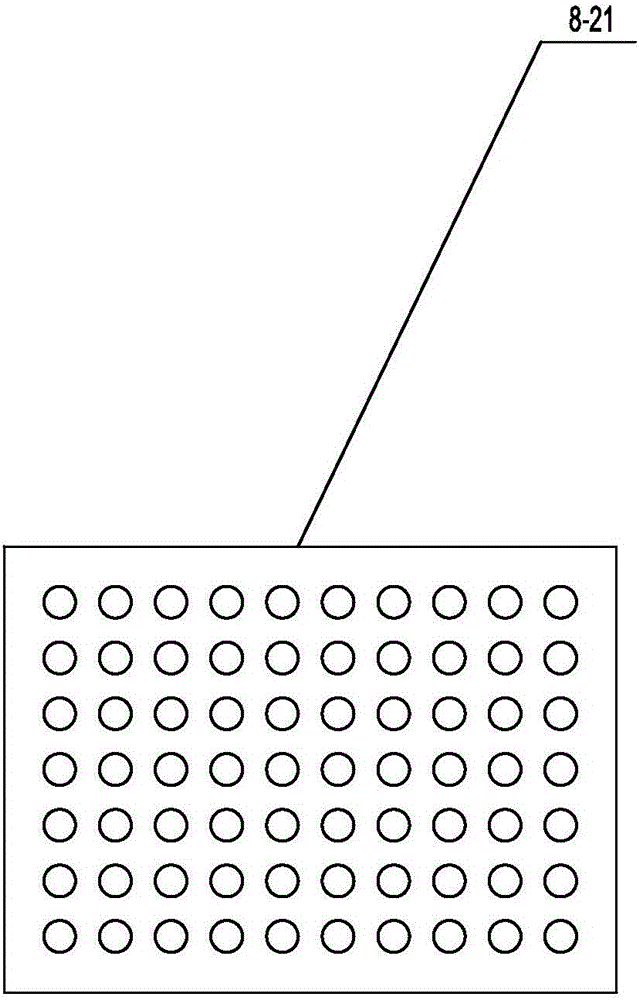

[0026] Such as figure 1 Propose a kind of specific embodiment of the present invention as shown, a kind of button cell automatic ink printing device, comprise frame 1, the front side of described frame 1 is provided with the left side that is connected with the battery disc of drive mechanism that can move up and down successively from left to right. The stacking frame 2, the three-cell battery tray mobile frame 3 connected with the front, rear, left, and right drive mechanisms, the right stack frame 4 of the battery tray connected with the front and rear drive mechanisms, and the rear side of the frame 1 is sequentially provided with connecting bars from left to right. The left stacking frame of the apron plate of the upper and lower drive mechanism 2, the three-section apron plate moving frame connected with the front, rear, left and right drive mechanism 3, the right stacking frame 4 of the apron plate connected with the front and rear drive mechanism, the bottom of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com