Method for preparing graphene/basic carbonate nanocomposite material

A nanocomposite material and graphene technology are applied in the field of preparation of graphene/basic carbonate nanocomposite materials to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation method of nanoscale graphene / basic carbonate composite material of the present invention, specific content is as follows:

[0021] (1) Disperse 0.05g functionalized graphene into 10mL0.0192mol / L Bi(NO 3 ) 3 ethylene glycol solution, then put the dispersion into a 20mL beaker, and then move the beaker to a 100mL hydrothermal reactor liner filled with 10mL ammonia water, seal it and keep it warm at 185°C for 12h; the functionalized graphene is Graphite oxide was prepared by the Hummes method, and then the prepared graphite oxide was flushed with nitrogen for 3 hours, then rapidly heated to 1050°C for thermal exfoliation;

[0022] (2) The product obtained from the solvothermal reaction was cooled, centrifuged, washed with absolute ethanol, and then vacuum-dried at 60°C for 12 hours, and the finally obtained powder was the graphene / bismuth subcarbonate nanocomposite material.

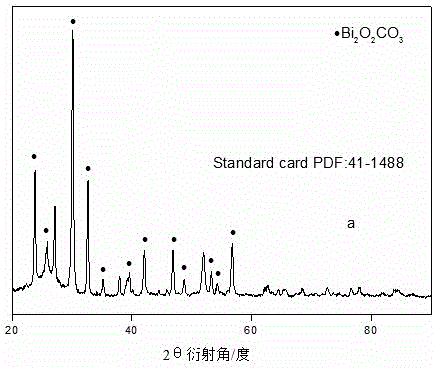

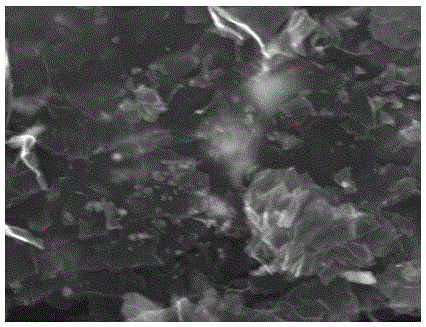

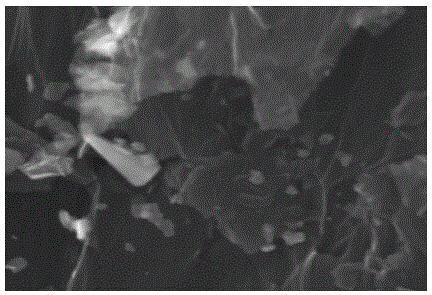

[0023] The X-ray diffraction figure and the scanning electron mic...

Embodiment 2

[0024] Embodiment 2: the preparation method of nanoscale graphene / basic carbonate composite material of the present invention, specific content is as follows:

[0025] (1) Ultrasonically disperse 0.05g of functionalized graphene into 5ml of 0.03mol / L magnesium nitrate solution in glycerol for 1h, then put the dispersion into a 20mL beaker, and then move the beaker to a place containing the graphene suspension A 100mL hydrothermal reactor liner with an equal volume of ammonia water was sealed and kept at 100°C for 24 hours; the functionalized graphene was prepared from graphite oxide by the Hummes method, and then the prepared graphite oxide was flushed with nitrogen for 3 hours and then heated rapidly to Obtained by thermal exfoliation at 1050°C;

[0026] (2) The product obtained from the solvothermal reaction was separated by vacuum filtration, washed with acetone, and then freeze-dried at ?45°C for 12 hours. The final powder obtained was the graphene / basic magnesium carbonat...

Embodiment 3

[0027] Embodiment 3: the preparation method of nanoscale graphene / basic carbonate composite material of the present invention, specific content is as follows:

[0028] (1) Ultrasonically disperse 0.05g of functionalized graphene into 50ml of 0.04mol / L copper nitrate polyethylene glycol solution for 6h, then put the dispersion into a 20mL beaker, and then move the beaker to a place containing the graphene solution A 100mL hydrothermal reactor liner with an equal volume of ammonia water was sealed and kept at 190°C for 1h; the functionalized graphene was prepared from graphite oxide by the Hummes method, and then the prepared graphite oxide was flushed with nitrogen for 3h, then rapidly heated to Obtained by thermal exfoliation at 1050°C;

[0029] (2) The product obtained from the solvothermal reaction was centrifuged, washed with absolute ethanol, and then supercritically extracted and dried for 6 hours; the final powder obtained was the graphene / basic copper carbonate nanocomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com