Method for measuring content of stibium in steel

A determination method and content technology, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of environmental and human harm, slow analysis speed, many interference factors, etc., and achieve less interference factors and high accuracy , the effect of low determination limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0023] The method steps of this specific embodiment are as figure 1 as shown,

[0024] Step 1: Prepare sample solution

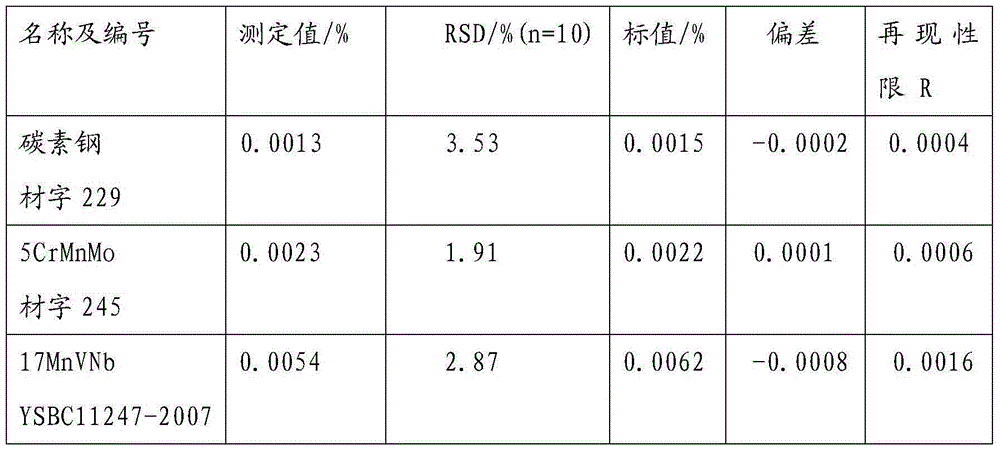

[0025] Take three standard samples, namely, carbon steel material 229, 5CrMnMo material 245, 17MnVNbYSBC11247-2007 standard samples, weigh 0.1000g of each standard sample in a polytetrafluoroethylene beaker, add 15-25mL of salt and nitric acid mixed acid , Salt-nitrate mixed acid is prepared from hydrochloric acid, nitric acid, and pure water at a volume ratio of 1:1:3. Heat and dissolve 2-3mL of hydrofluoric acid, transfer it to a plastic volumetric flask after cooling, and dilute to the 100mL mark with pure water. Shake well, hydrochloric acid is ρ1.19, superior grade pure hydrochloric acid, nitric acid is ρ1.42, superior grade pure nitric acid, hydrofluoric acid is ρ1.13, superior grade pure hydrofluoric acid, add and dilute with 1000μg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com