Material defect infrared thermal imaging detection and targeted elimination method in laser metal forming

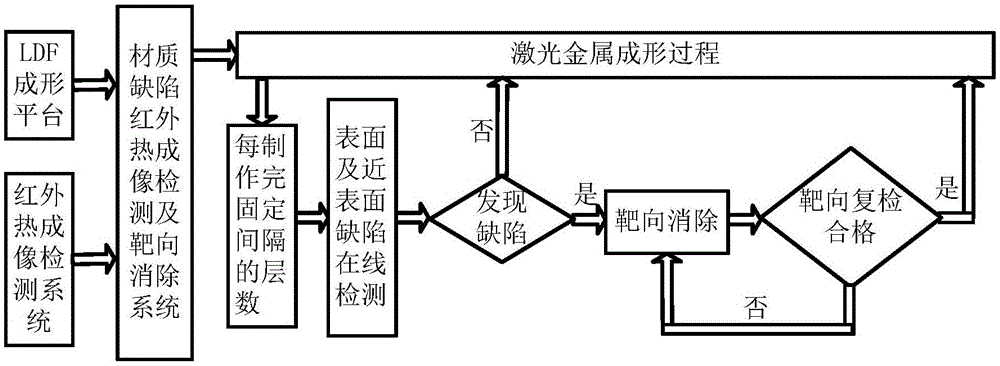

An infrared thermal imaging and metal forming technology, applied in material defect testing and other directions, can solve the problem of inability to detect and eliminate small material defects online, and achieve the effect of improving performance and service safety, reducing risks and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

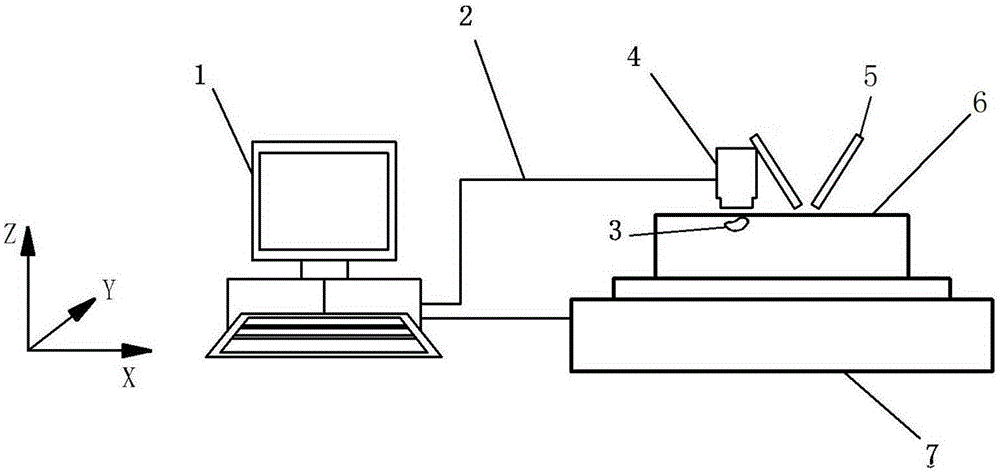

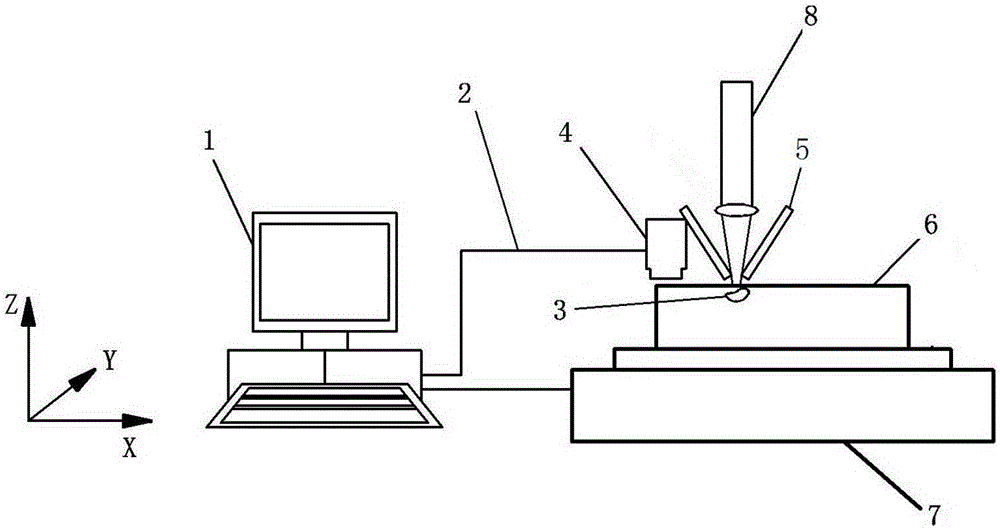

[0035] A TA15 titanium alloy cuboid with a length, width, and height of 100×30×50mm is produced by laser melting deposition forming technology, and the (x, y) coordinate orientation of the lower left corner of the workpiece in the forming plane is (100mm, 100mm). The forming process parameters used are: laser power 300W, scanning speed 10mm / s, powder feeding rate 4.9g / min, laser spot diameter 0.5mm, layer thickness 0.1mm, overlapping rate 40%, scanning method is reciprocating scanning . When making the material, the method of the present invention is used for online detection and targeted elimination of material defects, and the specific steps are as follows:

[0036]Step 1, every time 5 layers are finished, the production is suspended, and the computer 1 controls the workbench 7 to move at a constant speed in the horizontal direction at a speed of 20 mm / s, so that the lens of the infrared thermal imaging detector 4 fixed next to the powder feeding nozzle 5 is formed Non-cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com