Method for measuring gas flow of large-diameter pipe

A measurement method and technology for gas flow, which are applied in the fields of fluid mechanics, pipeline internal flow and bluff body flow, which can solve the problems of inconvenient transportation and installation, small pipeline diameter, large permanent pressure loss, etc. Blockage wear, small permanent pressure loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

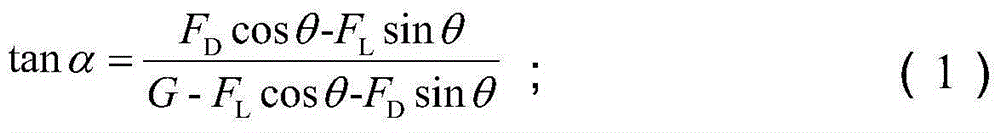

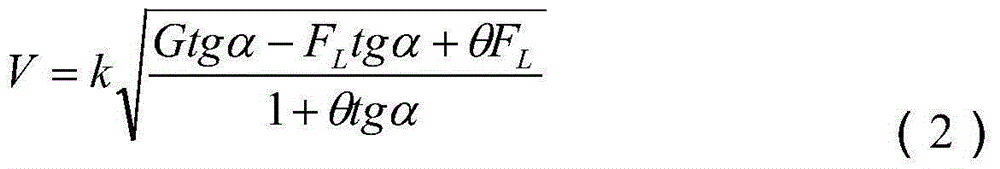

[0038] The method for measuring gas flow in large-diameter pipelines disclosed in the present invention is a method for measuring when the swing structure deflects under the action of fluid load to achieve force balance. The schematic diagram of its layout and principle analysis is as follows figure 1 As shown, the supporting structure in the flow measuring device is suspended on the top of the pipeline; under the action of the average incoming flow in the pipeline, the swinging structure in the measuring device deviates from the initial position, and reaches a force balance at a certain deflection angle; the measuring device The signal sensor and the microelectronic circuit control device in the pipeline are converted to obtain and output the average flow velocity or flow rate of the pipeline under the corresponding deflection.

[0039] The above-mentioned device is used to measure the air under normal temperature and pressure in a wind tunnel with a diameter of 300 mm (the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com