Gas flow measuring device for large-diameter pipes

A technology of gas flow and measuring device, which is applied in the field of pipeline internal flow and bluff body flow, and fluid mechanics, and can solve the problems of high performance requirements of differential pressure sensors, unsuitable for long-term online measurement, and inability to measure gas drainage pipelines. , to achieve the effect of easy production scale, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following examples are only used to illustrate the present invention, but are not used to limit the scope of the present invention. Unless otherwise specified, the methods used are commonly used methods in the art.

[0043] The device for measuring gas flow in large-diameter pipelines disclosed in the present invention will be described below with reference to the accompanying drawings and embodiments.

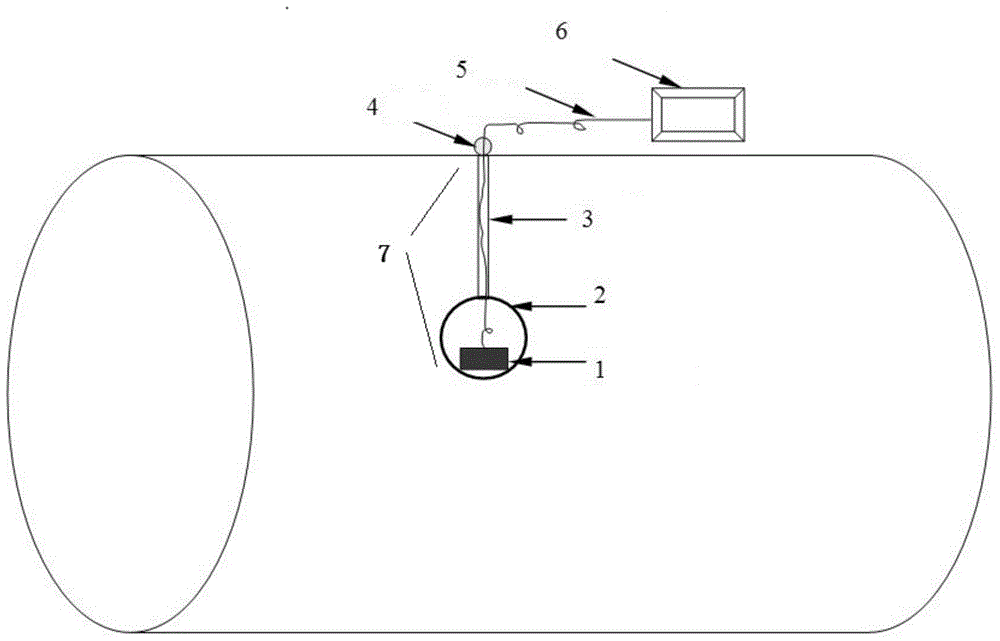

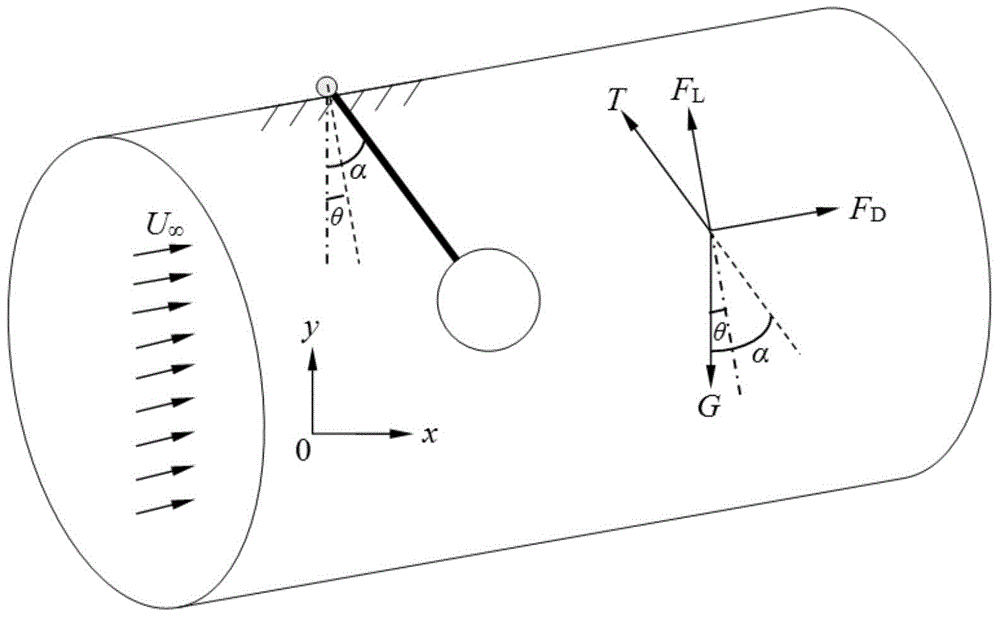

[0044] figure 1 It is a specific embodiment of the gas flow measuring device described in the present invention, which includes a swinging part 7 arranged in the gas pipeline fluid and a device for measuring the swinging angle of the swinging part.

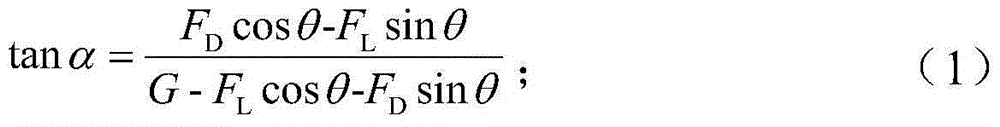

[0045] The swing part 7 of the present invention may include a fixed end 4 and a swing ball 2, the swing ball 2 can freely swing relative to the fixed end 4 under the action of an external force, the swing ball 2 is exposed to the fluid passing through the pipeline, The fixed end 4 is arranged outside the pipe; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com