Air pre-heater

An air preheater, flue gas side technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problems of air leakage of air preheater, accelerated low temperature corrosion, reduction of boiler efficiency, etc., to solve the problem of air leakage problems, increasing economic benefits, and the effect of good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

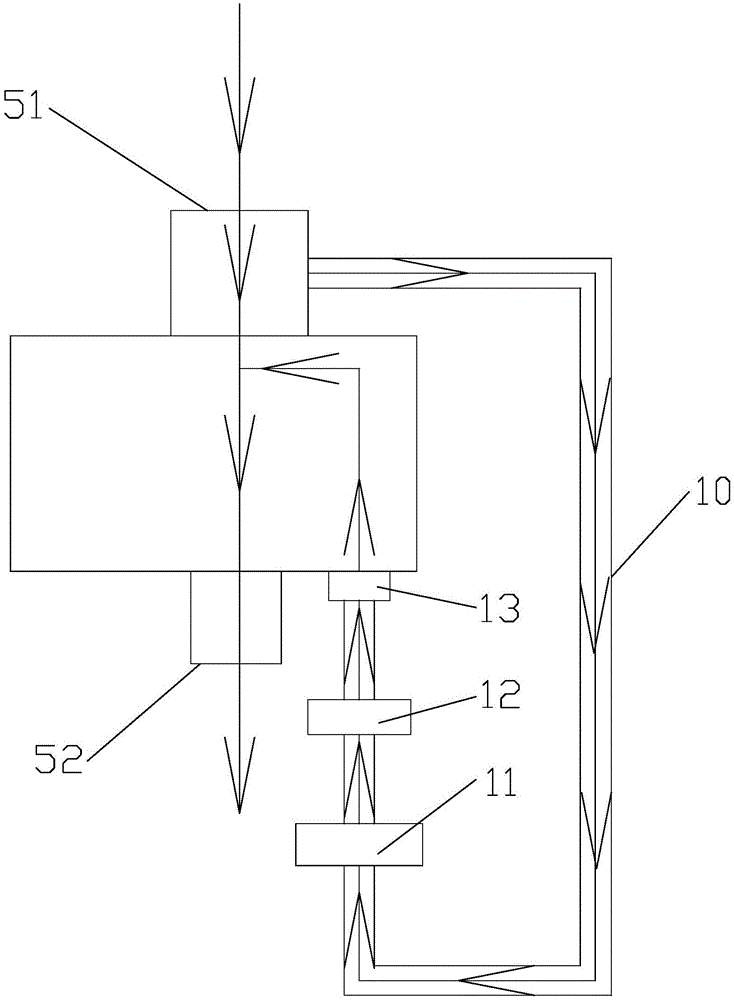

[0023] Embodiment: a kind of air preheater, as Figure 1-2As shown, it includes a rotor 2 with the rotor center tube 1 as the center of the circle. The rotor 2 has a plurality of compartments 3, and heat transfer elements are arranged in the compartments 3. Generally, three pairs of vertically symmetrical sectors are distributed on the upper and lower sides of the compartments 3. Plate 4, wherein two pairs of fan-shaped plates divide the rotor 2 into two semicircles of the same size, thereby dividing the rotor 2 into a smoke side 5 and an air side 6, and the air side 6 is divided into a primary air side by another pair of fan-shaped plates. side 61 and secondary air side 62, there is a casing 7 on the periphery of the rotor 2, and the top of the casing 7 is provided with a flue gas inlet 51 and a primary air outlet corresponding to the flue gas side 5, the primary air side 61, and the secondary air side 62 respectively. 611 and the secondary air outlet 621, the flue gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com