Movable upward raise boring machine

A raise drilling rig, mobile technology, applied in the field of mining machinery, can solve the problems of unsatisfactory drilling construction, increase construction difficulty, increase mining cost, etc., and achieve the effect of solving the difficulty of large-scale machinery transportation, reducing construction steps, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

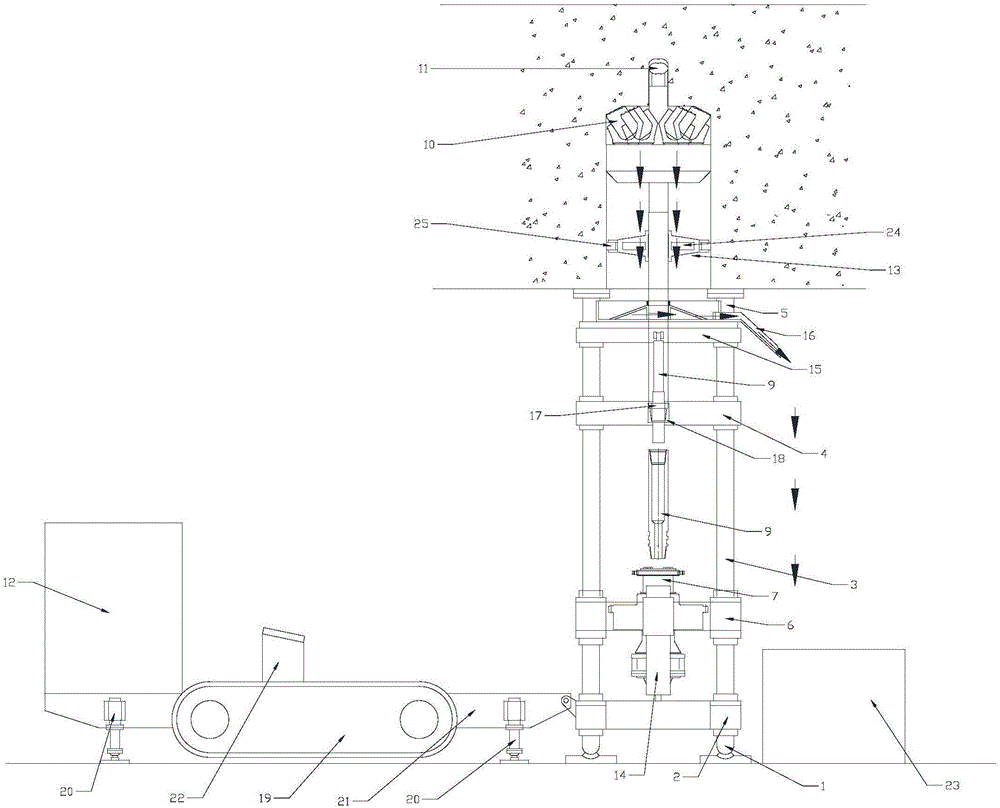

[0032] Such as Figure 1~3 As shown, the mobile upward raising drilling rig of the present invention includes a drilling rig support mechanism, a main thrust cylinder 6, a power head 7 and a drilling tool. The drilling rig support mechanism includes a lower support 1, a base 2, a guide column 3, a top beam 4 and Upper support 5; the upper end of the lower support 1 is fixedly connected to the lower end of the guide column 3, and the upper end of the guide column 3 is fixedly connected to the lower end of the upper support 5; the base 2 is installed near the guide On the guide column 3 at the lower end of the column 3, the top beam 4 is installed on the guide column 3 close to the upper end of the guide column 3, and the main push cylinder 6 is installed between the base 2 and the On the guide column 3 between the top beams 4, the main push cylinder 6 can slide along the guide column 3; the telescopic part 14 of the main push cylinder 6 is fixedly connected with the base 2, and...

Embodiment 2

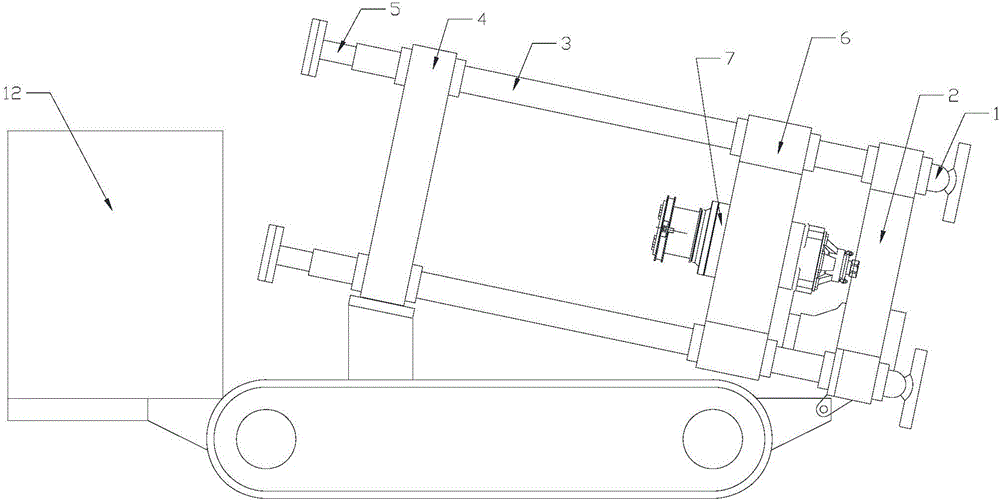

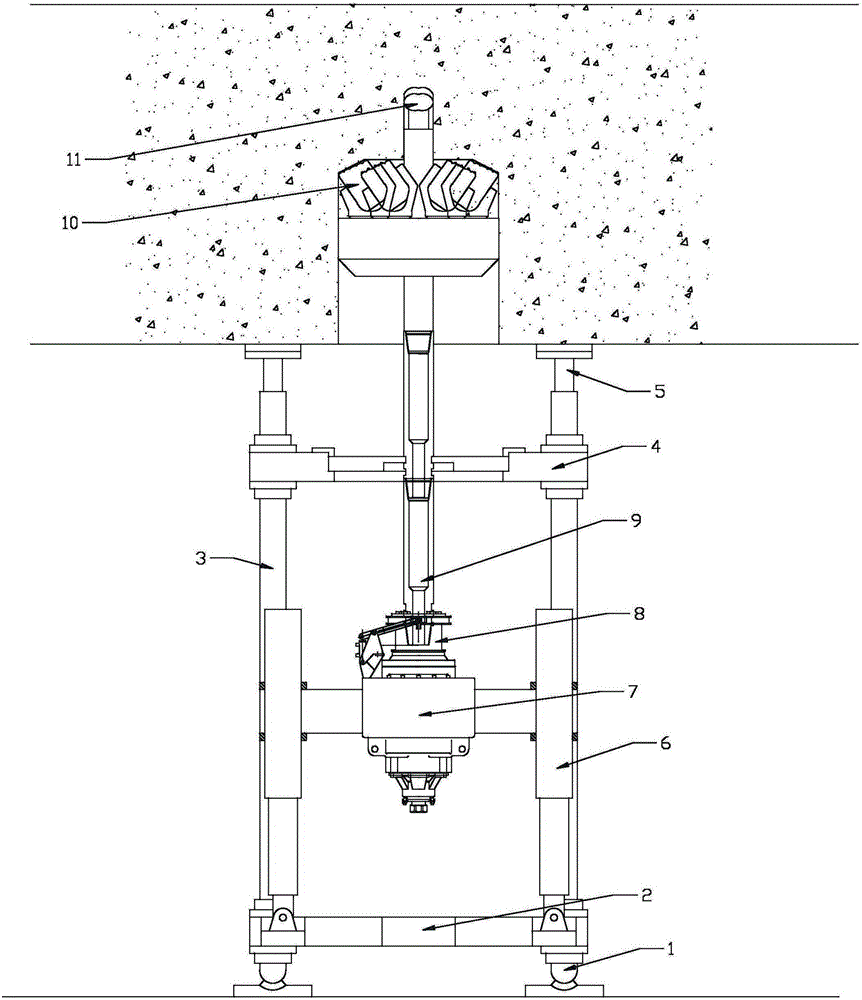

[0038] Such as Figure 4-9 As shown, the mobile upward drilling rig of the present invention includes a drilling device and a moving device.

[0039] Wherein, the drilling device includes a drilling rig support mechanism, a main thrust cylinder 6, a power head 7 and a drilling tool, and the drilling rig support mechanism includes a lower support 1, a base 2, a guide column 3, a top beam 4 and an upper support 5; The upper end of the support 1 is fixedly connected with the lower end of the guide column 3, and the upper end of the guide column 3 is fixedly connected with the lower end of the upper support 5; On the guide column 3, the top beam 4 is installed on the guide column 3 adjacent to the upper end of the guide column 3, and the main push cylinder 6 is installed on the top beam 4 between the base 2 and the top beam 4. On the guide column 3, the main thrust cylinder 6 can slide along the guide column 3; the telescopic part 14 of the main thrust cylinder 6 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com