Aspergillus oryzae fermentation liquid, liquid glucose prepared therewith through degradation of straw powder, and preparation method and application of the liquid glucose

A technology of Aspergillus oryzae and fermentation liquid, which is applied in the fields of fermentation engineering and enzyme engineering, and can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

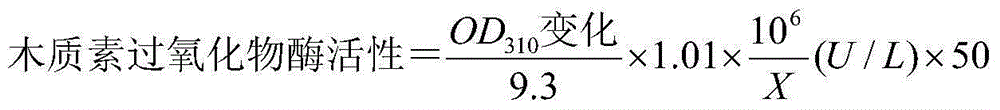

[0075] Embodiment 1 Aspergillus oryzae fermented liquid

[0076] Aspergillus oryzae fermented liquid contains lignin peroxidase enzyme activity 1000U / L and exocellulase enzyme activity 100U / L; Said aspergillus oryzae fermented liquid is raw material with rice straw powder, aspergillus oryzae is bacterial strain, expands successively through test tube Culture, liquid shake flask culture, seed tank seed culture and liquid fermentation culture process.

Embodiment 2

[0077] Embodiment 2 Aspergillus oryzae fermented liquid

[0078] Aspergillus oryzae fermentation broth contains lignin peroxidase enzyme activity 100U / L and exo-cellulase enzyme activity 300U / L; said Aspergillus oryzae fermentation broth is made of rice straw powder, and Aspergillus oryzae is a bacterial strain prepared according to the following steps :

[0079] a. test tube expansion culture: inoculate Aspergillus oryzae strains in potato glucose medium, and cultivate them at 35°C for 5 days to obtain Aspergillus oryzae test tube slant spores;

[0080] b. Liquid shake flask culture: Inoculate the slanted spores of Aspergillus oryzae test tubes into the shake flasks equipped with liquid shake flask culture medium, and cultivate them for 30 hours on a shaking table with a rotation speed of 110 rpm and a temperature of 30° C. to obtain liquid shake flask bacteria kind;

[0081] c. Seed culture in first-level seed tanks: inoculate the strains in liquid shake flasks into the me...

Embodiment 3

[0083] Embodiment 3 Aspergillus oryzae fermented liquid

[0084] The Aspergillus oryzae fermentation broth contains lignin peroxidase enzyme activity 500U / L and exocellulase enzyme activity 130U / L; the Aspergillus oryzae fermentation broth is prepared according to the following method:

[0085] a. test tube expansion culture: inoculate Aspergillus oryzae strains in potato glucose medium, cultivate 3d at a temperature of 25°C, and then preserve at 10°C to obtain Aspergillus oryzae test tube slant spores;

[0086] b. Liquid shake flask culture: Inoculate a ring of Aspergillus oryzae test tube slant spores into a 250mL Erlenmeyer flask containing 100mL of liquid shaker flask culture medium, and culture it on a shaker at a temperature of 38°C for 40 hours at a rotating speed of 50 rpm. , to prepare liquid shake flask strains;

[0087] C. First-class seed tank seed culture: by inoculum size is 12%, inoculate liquid shaking flask bacterial classification in the seed tank culture me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com