Aerobic denitrifying bacillus subtilis preparation and preparation method thereof

A Bacillus subtilis, aerobic denitrification technology, applied in biochemical equipment and methods, chemical instruments and methods, microorganism-based methods, etc., can solve problems such as poor biological denitrification technology, and achieve healthy and sustainable development. , the effect of easy cultivation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pick a loop of bacteria from the freeze-dried seeds of Bacillus subtilis GIM1.7152 and inoculate it into LB agar test tube slant medium, and cultivate at 37°C for 16 hours; transfer the test tube slant seeds to LB liquid medium at 37°C Shake culture for 20 hours to form a seed culture solution with a concentration of 2.0×10 8 cfu / mL.

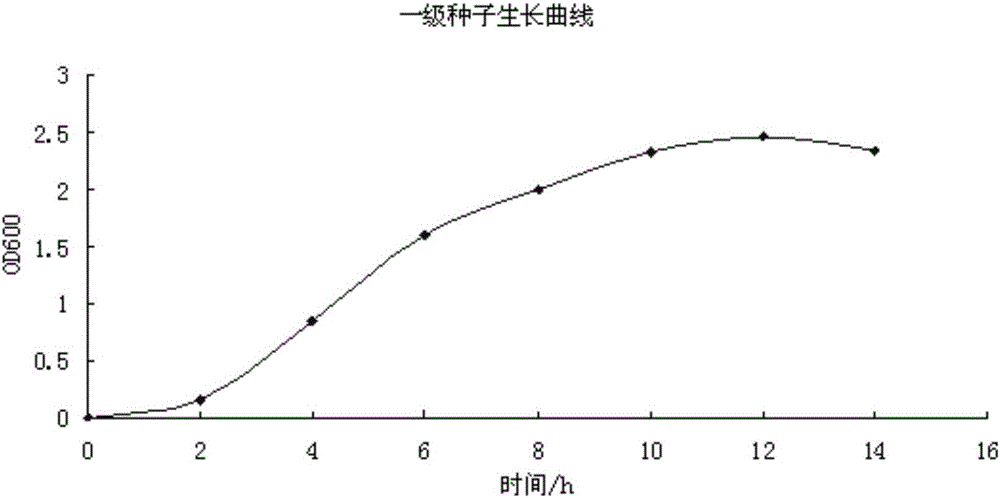

[0028] The seed culture solution was transferred to a 30L seed tank equipped with a primary fermentation medium at an inoculum of 3% (volume ratio) for fermentation culture, the filling volume was 70%, the fermentation temperature was 37±1℃, the stirring rate was 200rpm, and the aeration rate 0.8~0.9V / V·min, dissolved oxygen concentration 80~90%, take samples every 2h after inoculation to measure the absorbance at 600nm, use the uninoculated medium as a blank control to make the growth curve of Bacillus subtilis, such as figure 1 As shown, it can be seen from the curve that the number of Bacillus subtilis increases sharply in 8-12 hours, indi...

Embodiment 2

[0058] Pick a loop of bacteria from the freeze-dried seeds of Bacillus subtilis GIM1.7152 and inoculate it into LB agar test tube slant medium, and cultivate at 37°C for 20 hours; transfer the slant seeds of the test tube to LB liquid medium at 37°C Shake culture for about 25 hours to form a seed culture solution with a concentration of 1.1×10 9 cfu / mL.

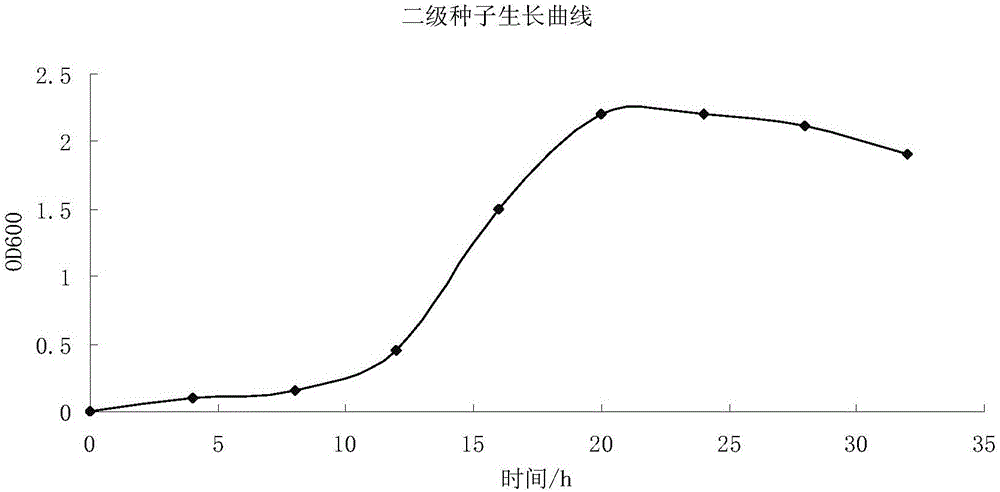

[0059] The seed culture solution was transferred to a 30L seed tank with a primary fermentation medium at an inoculum of 4% (volume ratio) for fermentation culture, the filling volume was 70%, the fermentation temperature was 37±1°C, the stirring rate was 300rpm, and the aeration rate 0.8-0.9V / V·min, dissolved oxygen concentration of 80-90%, fermentation time of 10h, made into first-class seed liquid. Transfer the first-level seed liquid to a 300L fermentor equipped with a second-level fermentation medium at an inoculum of 6% (volume ratio) for further expansion. The filling amount is 70%, the fermentation temperature is 37±1°C,...

Embodiment 3

[0066] Pick a loop of bacteria from the freeze-dried seeds of Bacillus subtilis GIM1.7152 and inoculate it into LB agar test tube slant medium, and culture at 37°C for 24 hours; transfer the test tube slant seeds to LB liquid medium at 37°C Shake culture for about 30 hours to form a seed culture solution with a concentration of 2.0×10 9 cfu / mL.

[0067] The seed culture solution was transferred to a 30L seed tank equipped with a first-level fermentation medium at a 5% (volume ratio) inoculum for fermentation culture, the filling volume was 70%, the fermentation temperature was 37±1℃, the stirring rate was 350rpm, and the aeration rate 0.8-0.9V / V·min, dissolved oxygen concentration 80-90%, fermentation time is 14h, the bacteria have reached the logarithmic growth phase after testing, and the first-level seed liquid is made. Transfer the first-level seed liquid to a 300L fermentor equipped with a second-level fermentation medium at an inoculum of 10% (volume ratio) to further expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com