Water-based conductive coating composition

A technology of conductive coatings and compositions, applied in conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of strong substrate corrosion, substrate disturbance or burst, weak corrosion, etc., to reduce corrosion effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

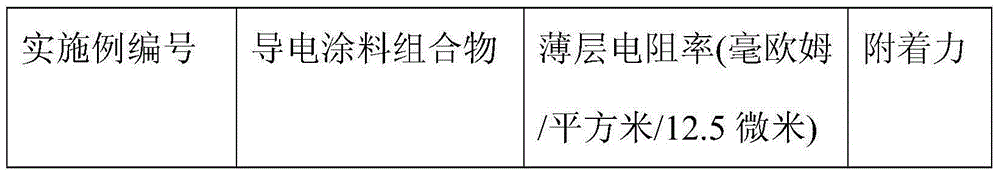

Examples

preparation example Construction

[0018] The preparation method of the conductive coating composition provided by the invention comprises mixing the conductive particles, water-soluble resin, curing agent and water in a formulated amount, and the mixing is carried out in a mixer or under the assistance of ultrasound.

[0019] The preparation method also includes adding auxiliary agents and mixing, and the types of the auxiliary agents include wetting and dispersing agents, anti-sedimentation agents, coupling agents and adhesion promoters. The amount of each auxiliary agent is such that in the prepared conductive coating composition, based on the total weight of the conductive coating composition, the content of the wetting and dispersing agent is preferably 0.1-5% by weight, more preferably 0.5-3% by weight %; the content of anti-settling agent is preferably 0.1-8% by weight, more preferably 0.5-5% by weight; the content of coupling agent is preferably 0.1-8% by weight, more preferably 0.5-5% by weight; adhesio...

Embodiment 1

[0023] This example is used to illustrate the conductive coating composition provided by the present invention.

[0024] 15 parts by weight of epoxy resin, 5 parts by weight of organically modified bentonite anti-settling agent 818 (produced by Elementis Specialties company), 2 parts by weight of wetting and dispersing agent (DP983, produced by Deqian Company), 2 parts by weight of monoalkoxy Titanate coupling agent T204 (manufactured by Nanjing Xiangfei Company) was mixed and stirred at a speed of 3000 rpm for 30 minutes. Add the average particle diameter of 16 weight parts then in the mixture that is obtained and be the spherical conductive silver powder (SA-1 of Kunming Science and Technology Hengda) of 1 micron and the flake conductive silver powder (PA-1) of 10 microns of average particle diameter of 10 weight parts 1D, Kunming Polytechnic Hengda), 2 parts by weight of curing agent Bayhydur2487, and then add 50 parts by weight of water, and stir at a speed of 3000 rpm for...

Embodiment 2

[0026] This example is used to illustrate the conductive coating composition provided by the present invention.

[0027]The water-based polyurethane resin of 25 parts by weight, the average particle diameter of 50 parts by weight are the spherical conductive silver powder (Ningxia Dongfang special material) of 1 micron, the curing agent VestanatB1358 / 100 of 8 parts by weight and the water of 25 parts by weight are mixed, with 2000 Stirring at a speed of rpm for 3.5 hours to obtain conductive coating composition S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com