Organic modified rectorite/EVA composite foam material and preparation method and application thereof

A technology of composite foam and rectorite, which is applied in the field of organic modified rectorite/EVA composite foam material and its preparation, can solve the problems of large deformation of materials and influence on mechanical properties, etc., and achieves high strength, easy operation and high cost performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

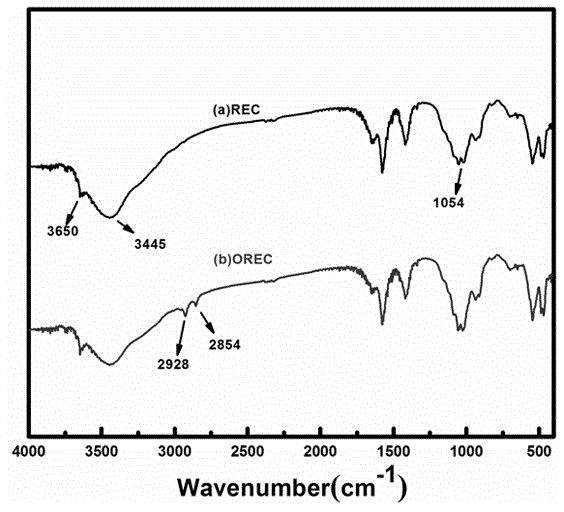

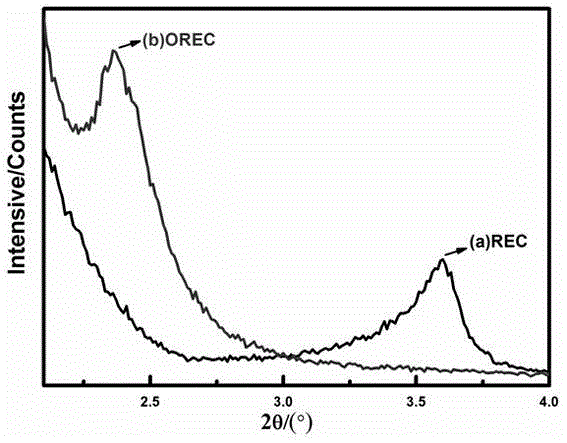

[0032] (1) Add 3 g of rectorite (REC) and 100 mL of deionized water into a round bottom flask, place it in a 100W ultrasonic cleaner for 10 minutes of ultrasonic dispersion to obtain a REC suspension.

[0033] (2) Then add 0.5g didodecyldimethylammonium bromide to the REC suspension and stir the reaction at 80°C for 4h. After the reaction, cool to room temperature and wash with deionized water for several times until silver nitrate Detection of Br-free - exist, vacuum-dried at 80°C for 24 hours to obtain organically modified rectorite (OREC), which was packed into bags for later use.

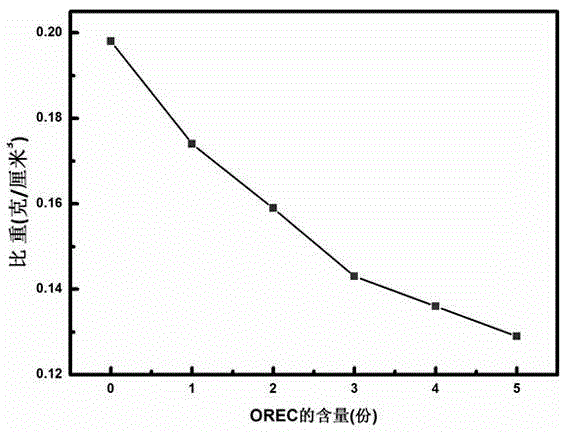

[0034] (3) Mix 3gOREC and 300gEVA uniformly for 5min in an internal mixer at a temperature of 120°C and a speed of 50rpm / min;

[0035] (4) Then add 7.5g foaming agent (AC), 2.7g crosslinking agent (DCP), 1.2g stearic acid (St), 1.8g zinc stearate (ZnSt), 2.1g auxiliary foaming agent (ZnO ) into the internal chamber of the internal mixer at a temperature of 120°C and a rotation speed of 25 rpm / ...

Embodiment 2

[0040] (1) Add 6g of rectorite (REC) and 100mL of deionized water into a round bottom flask, place it in a 100W ultrasonic cleaner for 10 minutes of ultrasonic dispersion to obtain a REC suspension.

[0041] (2) Then add 1g didodecyldimethylammonium bromide to the REC suspension and stir the reaction at 80°C for 4 hours. Br - exist, vacuum-dried at 80°C for 24 hours to obtain organically modified rectorite (OREC), which was packed into bags for later use.

[0042] (3) 6gOREC and 300gEVA were uniformly mixed for 5min in an internal mixer at a temperature of 120°C and a speed of 50rpm / min;

[0043] (4) Then add 7.5g foaming agent (AC), 2.7g crosslinking agent (DCP), 1.2g stearic acid (St), 1.8g zinc stearate (ZnSt), 2.1g auxiliary foaming agent (ZnO ) into the internal chamber of the internal mixer at a temperature of 120°C and a rotation speed of 25 rpm / min and continue mixing for 15 minutes to obtain a mixture;

[0044] (5) The mixture obtained in step (4) is quickly transf...

Embodiment 3

[0048] (1) Add 9 g of rectorite (REC) and 100 mL of deionized water into a round-bottomed flask, place it in a 100W ultrasonic cleaner for 10 minutes of ultrasonic dispersion to obtain a REC suspension.

[0049](2) Then add 1.5g didodecyldimethylammonium bromide to the REC suspension and stir the reaction at 80°C for 4h. After the reaction, cool to room temperature and wash with deionized water for several times until silver nitrate Detection of Br-free - exist, vacuum-dried at 80°C for 24 hours to obtain organically modified rectorite (OREC), which was packed into bags for later use.

[0050] (3) Mix 3gOREC and 300gEVA uniformly for 5min in an internal mixer at a temperature of 120°C and a speed of 50rpm / min;

[0051] (4) Then add 7.5g foaming agent (AC), 2.7g crosslinking agent (DCP), 1.2g stearic acid (St), 1.8g zinc stearate (ZnSt), 2.1g auxiliary foaming agent (ZnO ) into the internal chamber of the internal mixer at a temperature of 120°C and a rotation speed of 25 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com