Multifunctional sludge treatment aeration tank

A sludge treatment and aeration tank technology, applied in the field of sewage and sludge treatment technology, can solve problems such as affecting sewage or sludge treatment efficiency, long overall process operation time, and cumbersome operation, so as to facilitate unified planning and management. , optimize the production line, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

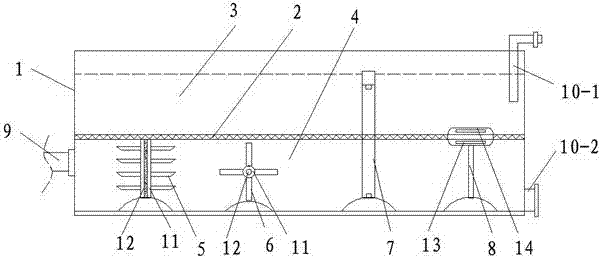

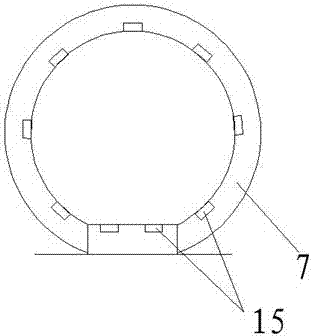

[0017] Embodiment 1: as figure 1 and 2 Shown is a multifunctional sludge treatment aeration tank, the aeration tank is a rectangular tank body 1, the middle part of the tank body 1 is provided with a horizontal separation screen 2, the separation The screen 2 divides the pool body 1 into a sewage area 3 and a sludge area 4, and the two ends of the pool body 1 are respectively provided with a feed port 9 and a discharge port 10-1, 10-2, and the feed port 9 Between the discharge port 10-1 and 10-2, a primary processing device 5, a secondary processing device 6, a tertiary processing device 7 and a fourth processing device 8 are successively arranged, and the primary processing device 5 is a vertical stirring Paddle, the secondary treatment device 6 is a horizontal stirring paddle, the three-stage processing device is a ventilation ring 7, the fourth-stage processing device is a T-type sterilization table 8, and the vertical stirring paddle 5 and horizontal stirring paddles 6 a...

Embodiment 2

[0018] Embodiment 2: as figure 1 and 2 As shown, the discharge port of the present invention includes a sludge discharge port 10-2 and a sewage discharge port 10-1, and the sludge discharge port 10-2 is arranged at the bottom of the sludge area 4, so The above-mentioned sewage discharge port 10-1 is set above the sewage area 3, and the sludge and sewage are respectively discharged through the sludge discharge port 10-2 and the sewage discharge port 10-1, thereby completing the preliminary separation of sludge and sewage Easy to operate and optimize the overall production line.

Embodiment 3

[0019] Embodiment 3: as figure 1 and 2 As shown, the first-level treatment device 5, the second-level treatment device 6, the third-level treatment device 7 and the fourth-level treatment device 8 of the present invention are evenly distributed in the pool body 1, and the distance between two adjacent devices is The same; the four sets of treatment devices 5, 6, 7, and 8 are used to treat sludge and sewage in different ways. In order to avoid the influence of different treatment devices, there is a certain installation distance between the four devices, which is convenient for unification planning and management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com