PE foaming once-molded large rotational molding packaging box and manufacturing process thereof

A packaging box and rotomolding technology, applied in the field of rotomolding, can solve the problems of cumbersome operation, low work efficiency, stacking (dynamic flow, etc.), and achieve the effects of simplifying the process, ensuring productivity, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

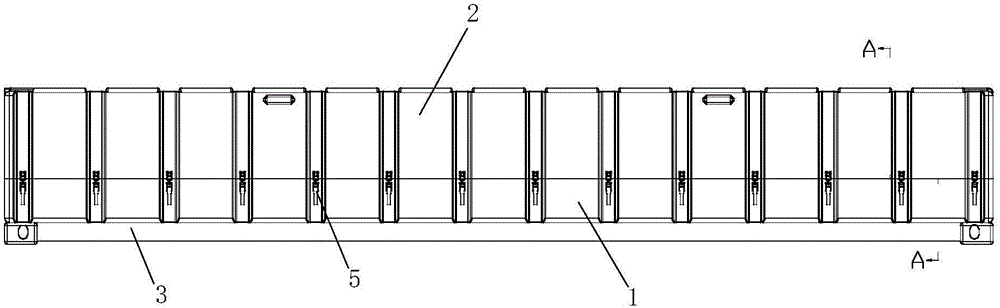

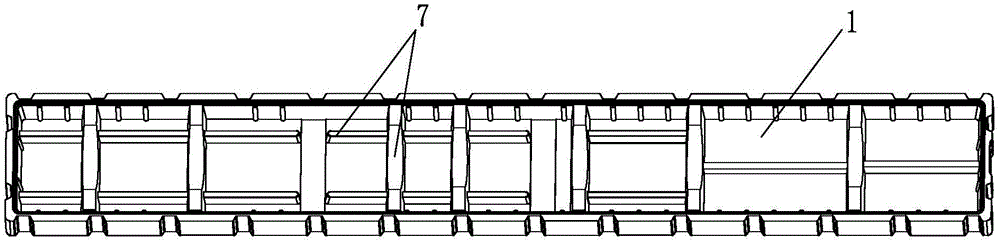

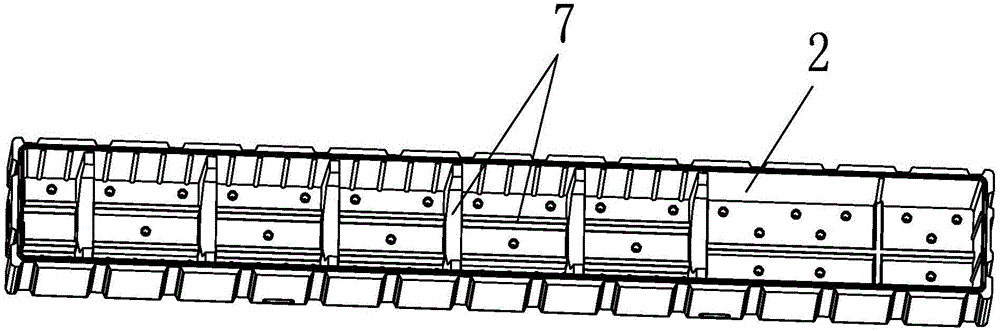

[0027] Such as Figure 1~4 The large-scale rotomolded packaging box is molded by PE foaming as shown, which includes a rotomolded packaging box body 1, a rotomolded packaging box cover 2 that matches the rotomolded packaging box body 1, and is arranged on the rotomolded packaging box body. 1 the bottom bracket 3 at the bottom, the sealing rubber strip 4 arranged between the rotomolding packaging box body 1 and the rotomolding packaging box cover 2 connection (the sealing rubber strip 4 is used to realize the sealing function of the rotomolding packaging box, Watertight or airtight), is arranged between the rotomolding box body 1 and the rotomolding box cover 2 connection and can fix the rotomolding box body 1 and the rotomolding box cover 2 Lock 5, the shells of the rotomolding box body 1 and the rotomolding box cover 2 are polyethylene shells,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com