The shank is taken and cut by the horizontal machine and put into the vertical machine for secondary glue injection and packing system

A horizontal machine and vertical machine technology, applied in the direction of coating, etc., can solve the problems of low work efficiency, high efficiency, low cost, high labor cost, etc., so as to improve production efficiency, reduce labor usage, and achieve automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

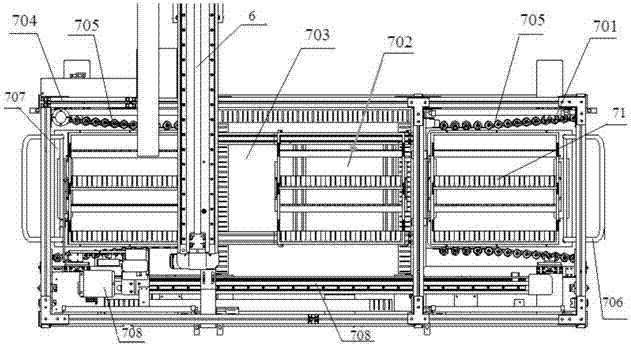

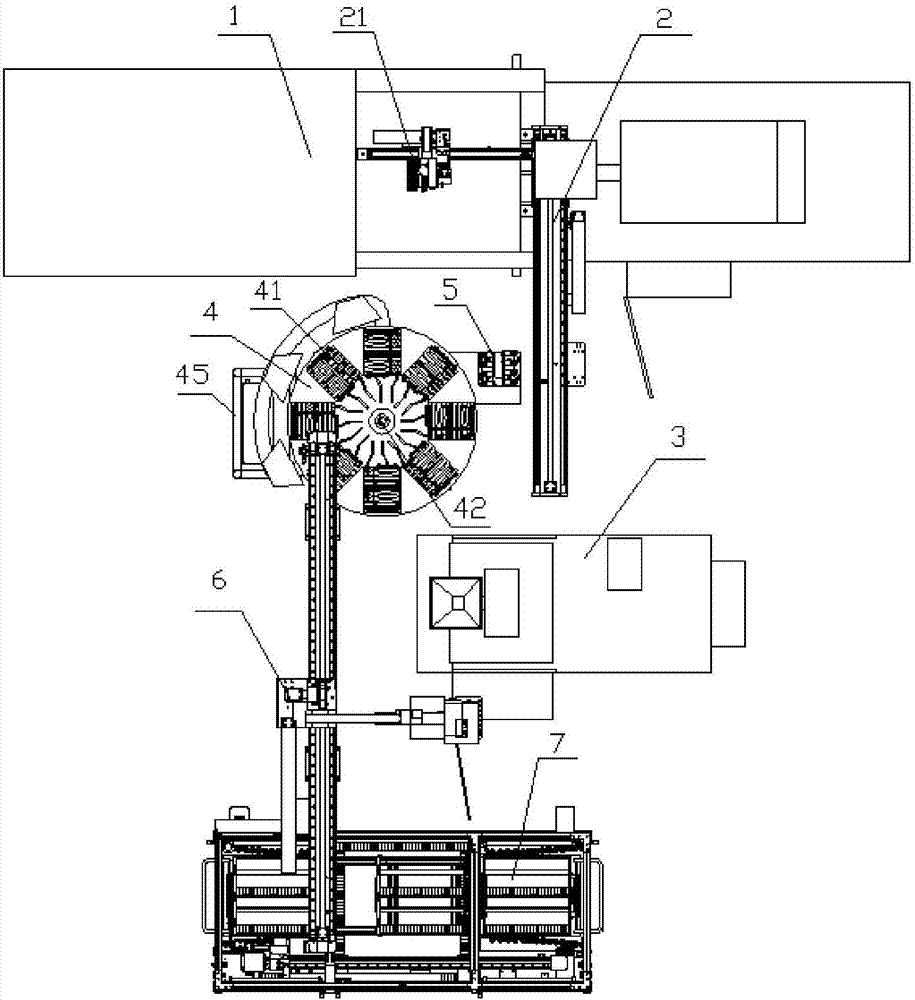

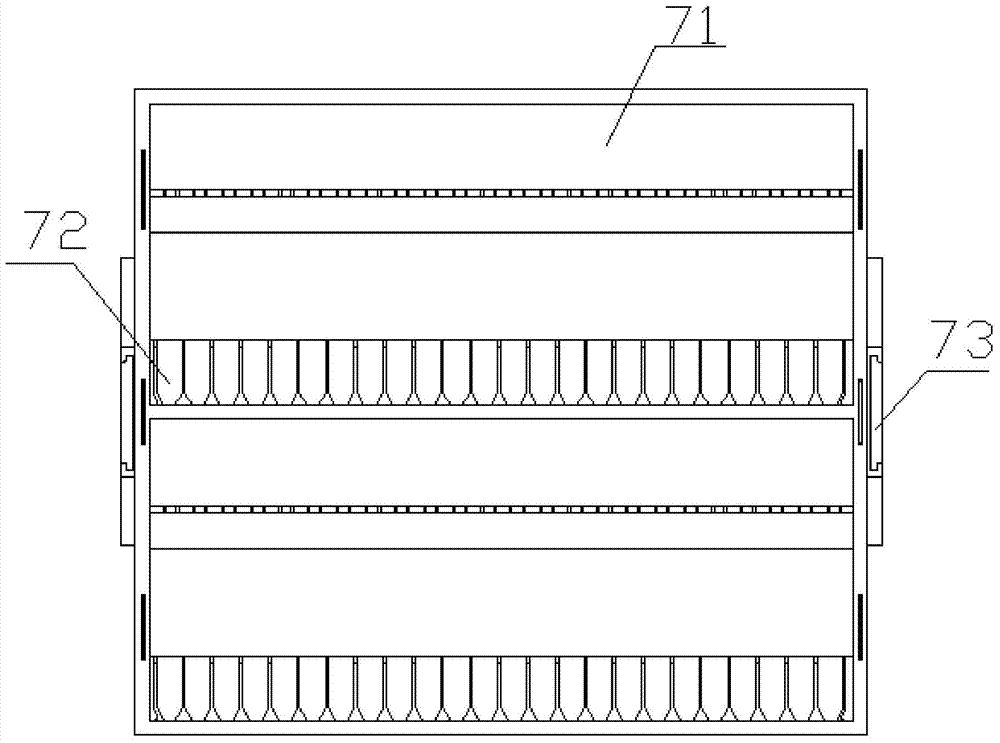

[0028] Such as Figure 1-5 As shown, this embodiment discloses a tooth handle that is taken out by a horizontal machine and put into a vertical machine for secondary glue injection and packing system. According to the process of the system, it includes: three-axis full servo manipulator 2, air shear fixture 5. Rotary conveyor 4, vertical injection molding machine 3, three-axis full-servo truss robot 6 and automatic stacker 7, the above-mentioned three-axis full-servo manipulator 2 grabs several brushes from the inside of the mold opening mold 1 through the grabbing fixture 21 The handle moves to the air shear fixture 5, and the air shear 51 on the above-mentioned air shear fixture 5 cuts off the material head of the brush handle, and then puts the cut brush handle on the above-mentioned rotary conveyor 5, and the rotary conveyor 5 is equipped with There is a cooling fan to cool the sizing brush handle on the above-mentioned rotary conveyor 5, and the above-mentioned three-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com