Visible grinding machine with automatic fine correction function

A micro-correction, grinding machine technology, applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding machine parts, etc. The effect of deviation and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

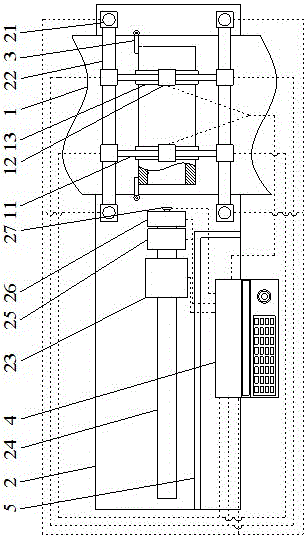

[0015] Such as figure 1 As shown, a visual automatic micro-calibration grinder includes an operating table 1, a grinder table 2 arranged under the operating table 1, and a control system 4 arranged on the grinder table 2; the operating table 1 is an assembly line; both sides of the operation table 1 are provided with rotatable stop bars 3; on both sides of the operation table 1 are installed two Z-axis numerical control slide rails 21 on the grinder table 2; operation table 1 Between the two Z-axis numerical control slide rails 21 corresponding to both sides, an X-axis numerical control slide rail 22 is arranged across the operating table 1; two Y-axis numerical control slide rails 11 are erected between the two X-axis numerical control slide rails 22 The Y-axis numerical control slide rail 11 is provided with a clamping jaw slider 12; the clamping jaw slider 12 is fixed with a clamping jaw 13 for fixing the workpiece; the grinding wheel machine 2 is also fixed with a grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com