Axial locking device applied to processing course of engine crankshaft

A crankshaft processing and axial locking technology, applied in the direction of clamping device, positioning device, metal processing equipment, etc., can solve the problems of axial movement, increased production cost, large dynamic balance value, etc. The effect of fluctuating, reducing scrap rate and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

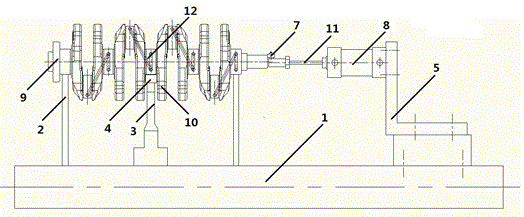

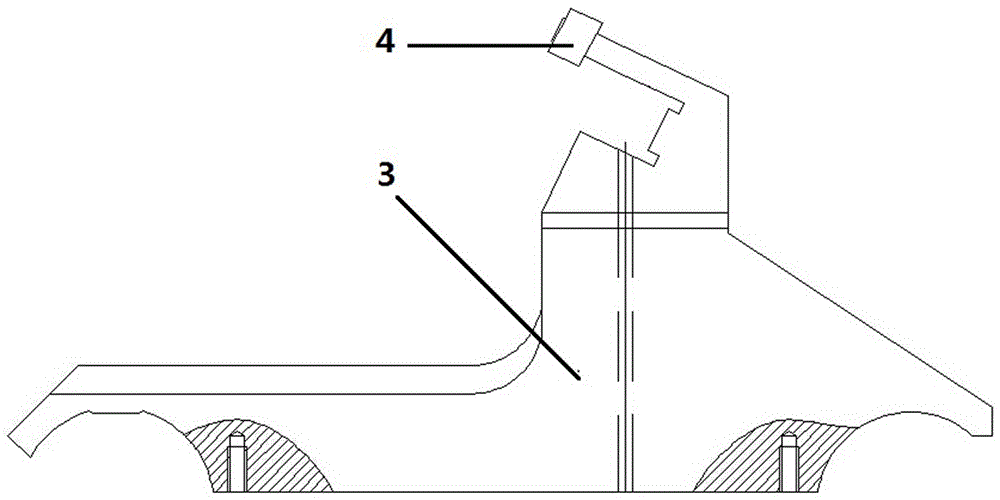

[0016] Such as figure 1 As shown, 1 is the base, 2 is the support frame, 3 is the bracket, 4 is the bearing I, 5 is the tailstock, 6 is the telescopic assembly, 7 is the bearing II, 8 is the cylinder (hydraulic or pneumatic), 9 is the crankshaft, The 10th is a fan plate, the 11th is a push rod, and the 12th is a journal.

[0017] The processing method of the original equipment: put the two ends of the crankshaft 9 on the support frame, start the machine button, the claws clamp the crankshaft 9, and drive the crankshaft 9 to rotate. move. The automatic sensing device of the machine tool automatically calculates the unbalanced value, and the external tool drills the fan plate 10 to achieve the purpose of removing the weight of the fan plate 10, so as to ensure that the unbalanced value of the crankshaft is within the specified range.

[0018] During the above-mentioned processing, due to the limited solid capacity of the top, the crankshaft 9 is prone to movement.

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com