One-piece forming method of ultra-slender thin-walled seamless metal pipe

A technology of seamless metal pipe and forming method, applied in the field of metal pipe preparation, can solve the problems of inability to meet application requirements, decrease in the compactness of welded joints, difficult operation and completion of the welding process, etc., and achieve good mechanical processing strength and smooth transition. , the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034]Step 1. Mix the plasticizer and metal powder A uniformly in a mass ratio of 5:50 to obtain a mixture A, and uniformly mix the plasticizer and metal powder B in a mass ratio of 5:50 to obtain a mixture B, and then partly describe The mixture A and part of the mixture B were uniformly mixed at a mass ratio of 1:2 to obtain a mixture C; the metal powder A and the metal powder B were both 316L stainless steel powders, and the average particle diameter of the metal powder A was 22 μm. The average particle diameter of the metal powder B is 34 μm, the mass of the mixture C is 50% of the mass of the mixture A, and the plasticizer is paraffin;

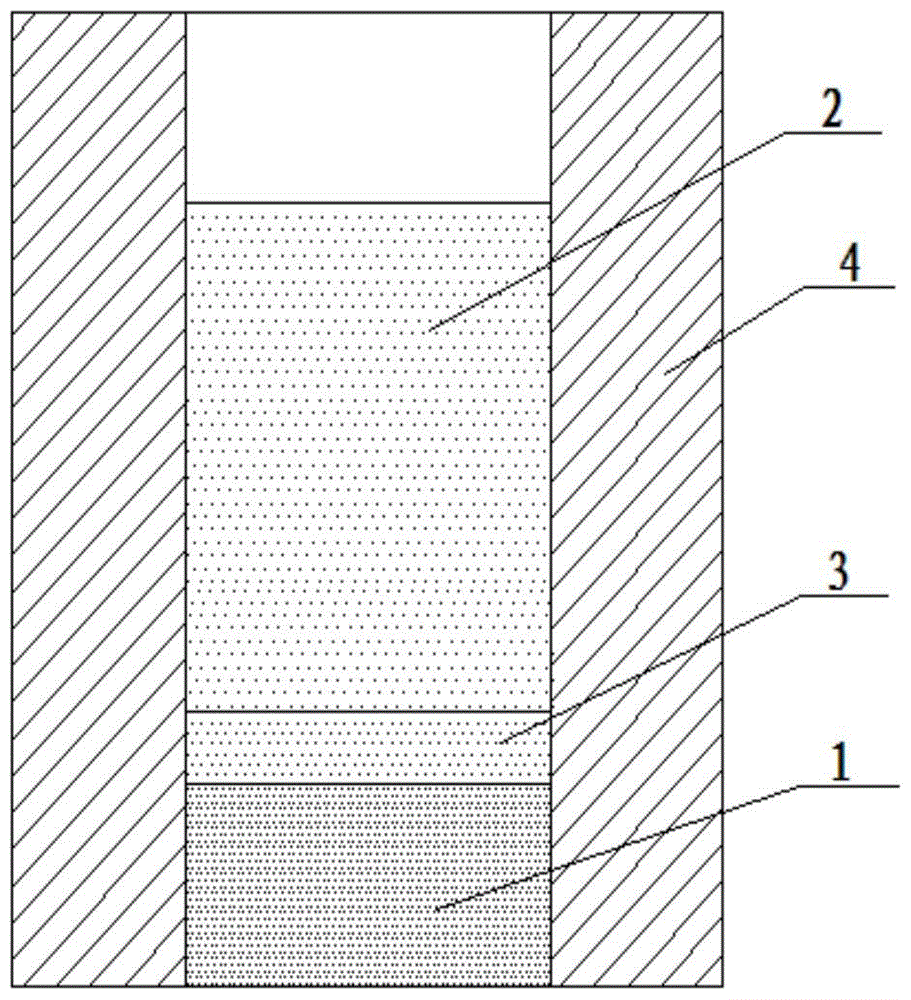

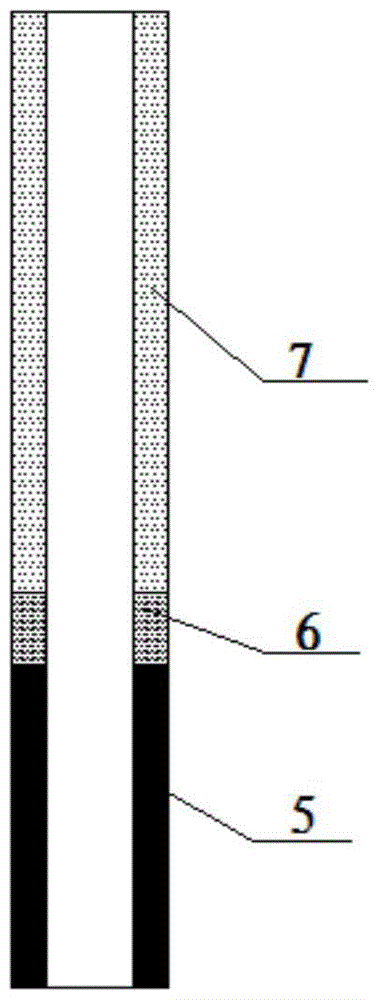

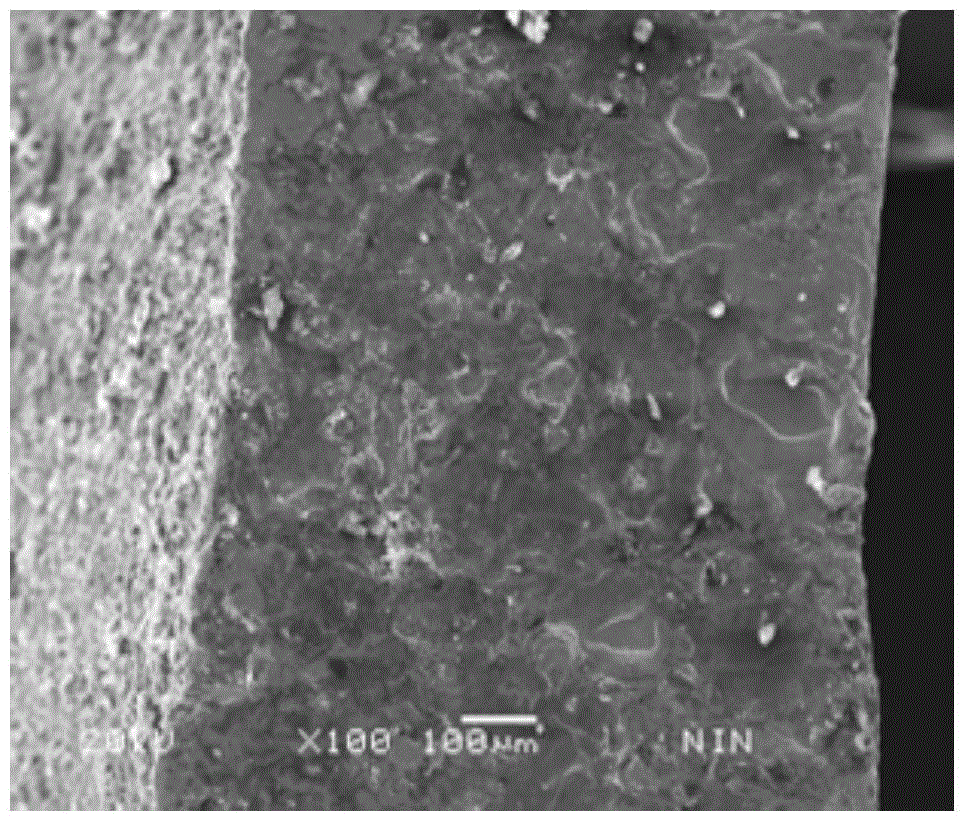

[0035] Step two, such as figure 1 As shown, the remaining mixture A in step 1 is extruded into a billet at a temperature of 40°C to obtain the first billet 1, and the remaining mixture B in step 1 is extruded into a billet at a temperature of 40°C , to obtain the second blank 2, ext...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] Step 1. Mix the plasticizer and metal powder A uniformly in a mass ratio of 7:50 to obtain a mixture A, and uniformly mix the plasticizer and metal powder B in a mass ratio of 7:50 to obtain a mixture B, and then partly describe The mixture A and part of the mixture B are uniformly mixed at a mass ratio of 1:1 to obtain a mixture C; the metal powder A and the metal powder B are both nickel powders, and the average particle diameter of the metal powder A is 110 μm, so The average particle diameter of the metal powder B is 150 μm, the mass of the mixture C is 35% of the mass of the mixture A, and the plasticizer is paraffin;

[0044] Step two, such as figure 1 As shown, the remaining mixture A in step 1 is extruded into a billet at a temperature of 45°C to obtain the first billet 1, and the remaining mixture B in step 1 is extruded into a billet at a temperature of 45°C , to obtain the second blank 2, extruding the ...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] Step 1. Mix the plasticizer and metal powder A uniformly in a mass ratio of 6:50 to obtain a mixture A, and uniformly mix the plasticizer and metal powder B in a mass ratio of 6:50 to obtain a mixture B, and then partly describe The mixture A and part of the mixture B are uniformly mixed at a mass ratio of 1:3 to obtain a mixture C; the metal powder A and the metal powder B are both Fe-Al intermetallic compound powders, and the average particle size of the metal powder A is diameter is 80 μm, the average particle diameter of the metal powder B is 130 μm, the mass of the mixture C is 50% of the mass of the mixture A, and the plasticizer is carboxymethyl cellulose;

[0052] Step two, such as figure 1 As shown, the remaining mixture A in step 1 is extruded into a billet at a temperature of 35°C to obtain the first billet 1, and the remaining mixture B in step 1 is extruded into a billet at a temperature of 35°C , to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com