Anti-detonation dual-wedge-surface self-locking cable sealing method

A cable sealing and wedge surface technology, applied in the direction of cable entry sealing device, cable accessories, cable installation, etc., can solve the problem of blasting and leakage of the detonating cable, achieve low cost, simple processing technology, and ensure the effect of tightening and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

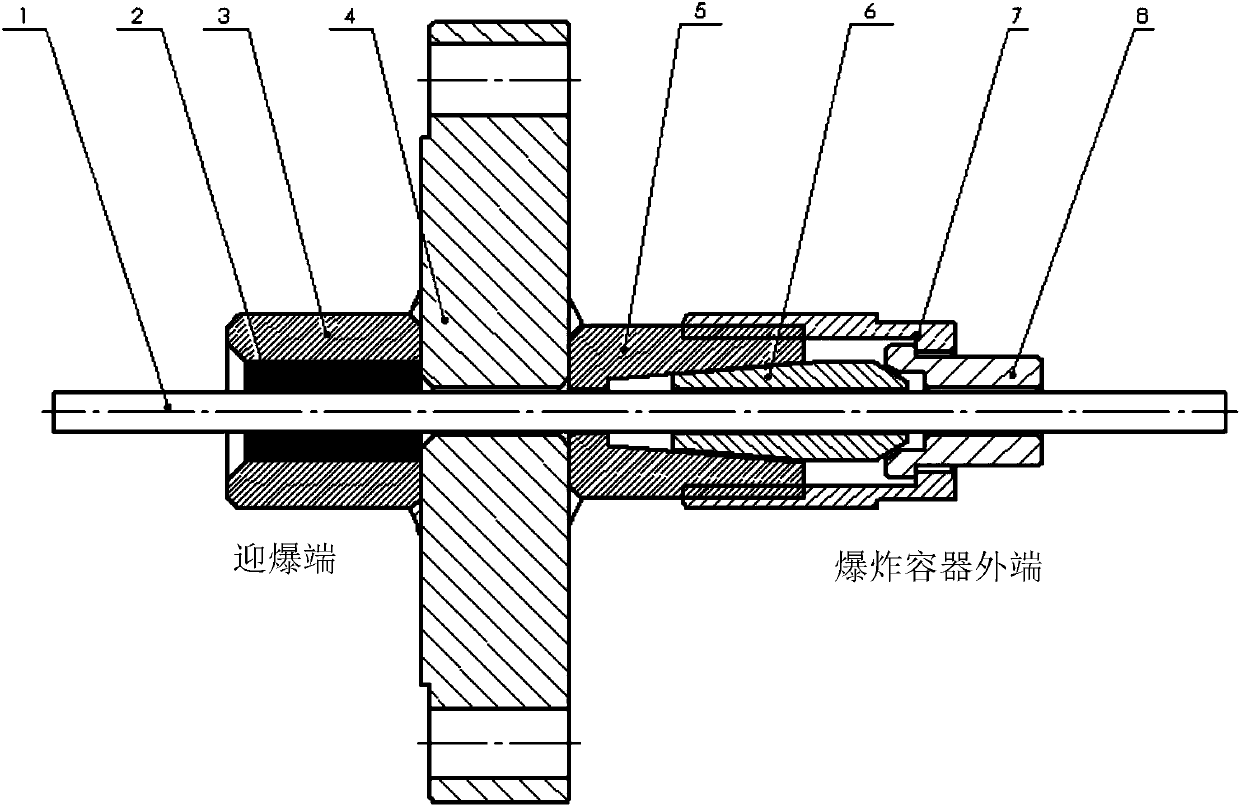

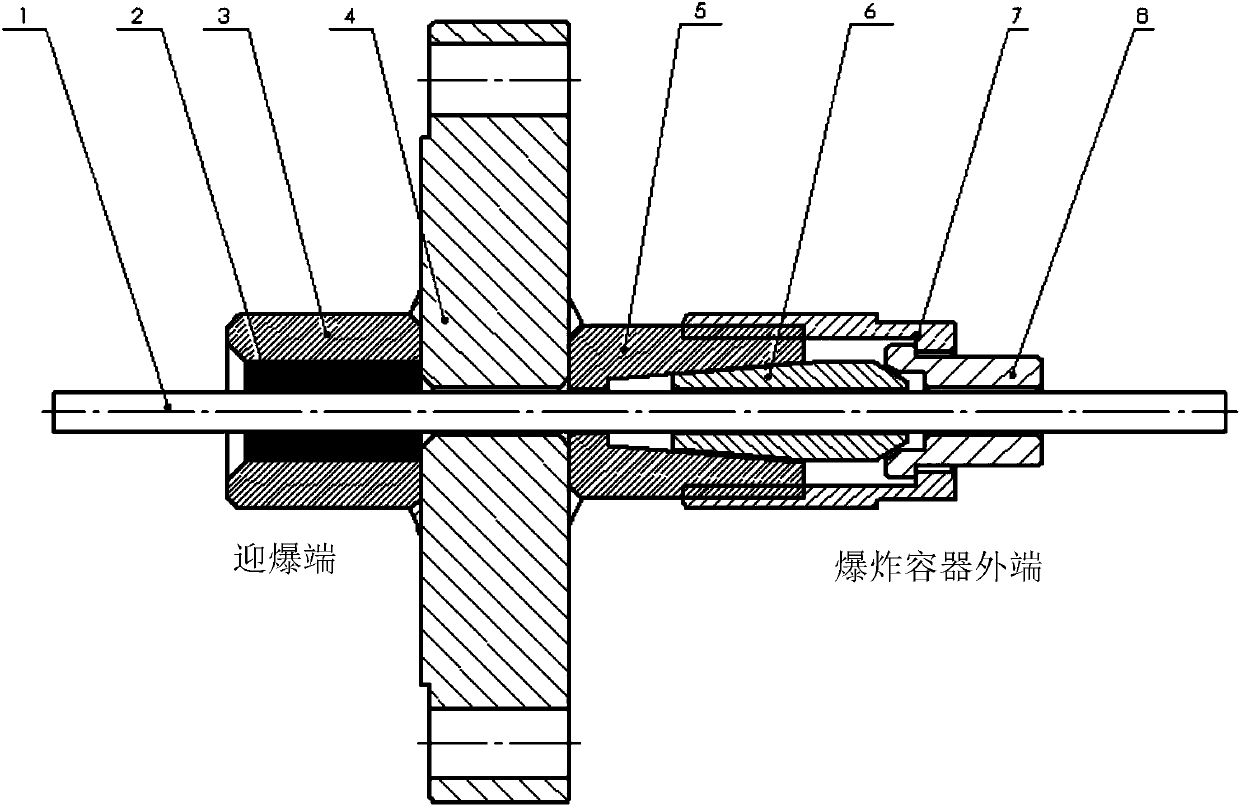

[0009] Such as figure 1 As shown, the self-tightening body is a hollow structure with wedge surfaces at the front and rear ends. When the cable passes through the self-tightening body, the lock nut is tightened and contacts the rear end wedge surface of the self-tightening body through the wedge surface of the spacer, and the The front wedge surface is pressed into the wedge surface cavity of the self-tightening section, and as the self-tightening body is pressed into its two ends, the wedge surface clamps the cable and fills the airtight material filling section with soft clay airtight material. After the explosion, on the one hand, the shock wave presses the airtight material into the inner cavity of the self-tightening section to ensure the sealing; on the other hand, if the cable moves outward under the action of the impact force, it will drive the wedge surface at the other end of the self-tightening body to compress the cable again, A tight seal is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com