Aluminum electrolysis anode steel jaw graphite spraying system and spraying method utilizing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

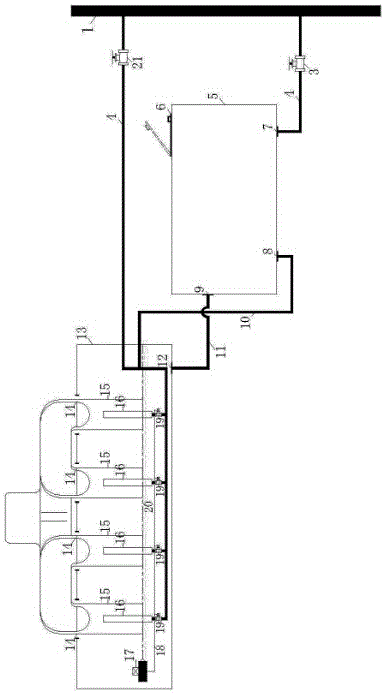

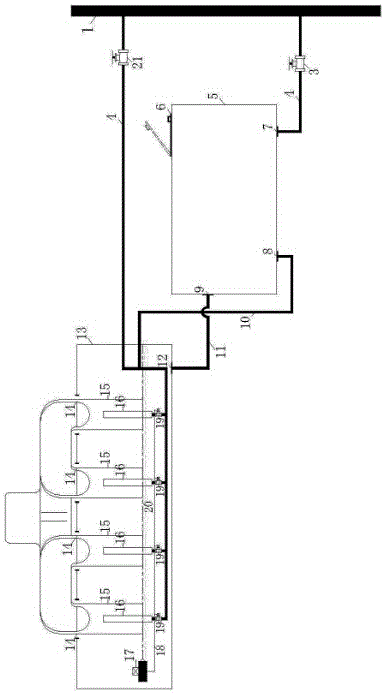

[0034] Reference attached figure 1 , an aluminum electrolysis anode steel claw automatic graphite spraying system, including a compressed air pipe network 1, a storage box 5, a working box 13, a first compressed air pipeline 21, a second compressed air pipeline 4, a feeding pipe 10 and multiple An electromagnetic control valve 19. Among them, the compressed air pipe network 1 is used to provide gas source; the top of the storage box 5 has a feeding port 6, the upper part of the side wall is provided with an inflow port 9, and the bottom is provided with a material outlet 8 and a compressed gas inlet 7 for placing graphite and solvent; working The upper surface of the box 13 is provided with a plurality of steel claw inlets 14 with a circular cross-section, an inductor 17 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com