Multi-stage separation sand machining production line

A production line and sand selection technology, used in solid separation, wet separation, sieving and other directions, can solve the problems of excessive ultrafine powder content, over-grinding, affecting the yield of silica sand particles and unit manufacturing costs, and reducing material loss. , reduce over-grinding and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

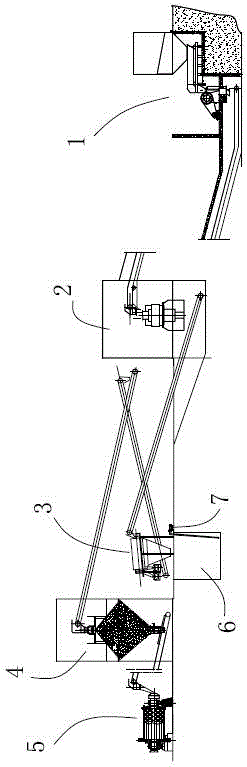

[0023] Embodiment: a kind of multistage sorting sand processing production line (see attached figure 1 ), including primary pre-selection system 1, crusher 2, secondary screening system 3, silo 4, mill 5 and post-grinding pool. The primary pre-selection system is connected to the crusher through the belt, the secondary screening system is connected to the crusher through the large particle return belt, the secondary screening system is connected to the silo through the medium particle front conveyor belt, and the lower part of the secondary screening system is equipped with small particle collection Pond 6, collection pool is connected with the magic back pool by slurry pump 7 and pipeline. The crusher is divided into two stages, the first-stage jaw crusher and the second-stage cone crusher. The two stages are connected by a belt, and the large particle return belt is connected to the second-stage cone crusher. Mills include rod mills or ball mills.

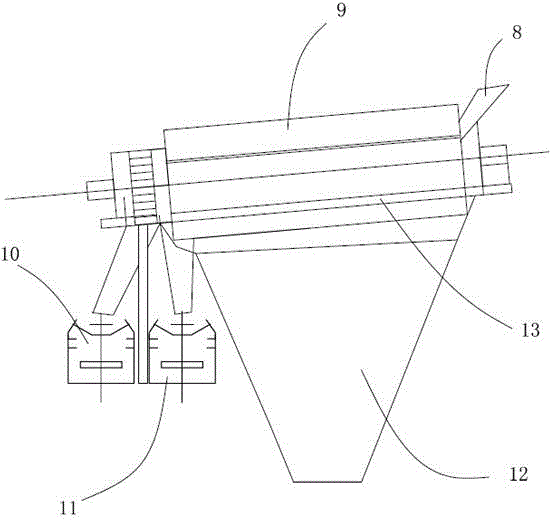

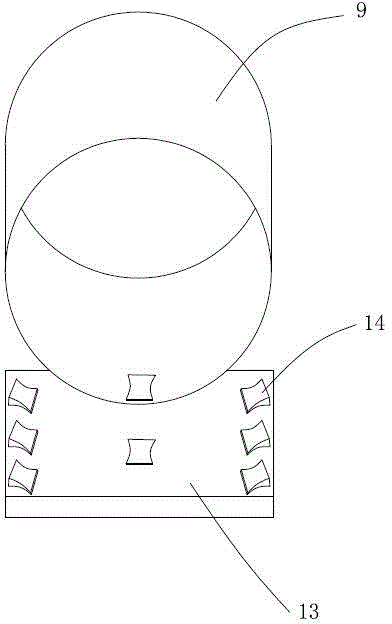

[0024] Secondary screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com