Pressure-infiltration coating device and method applicable to porous ceramic matrix photocatalytic filler block

A technology of porous ceramics and coating devices, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Problems such as the inability of the precursor plating solution to penetrate into the pores of the core to achieve the effects of high coverage of the loaded film, simple structure, and improved penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

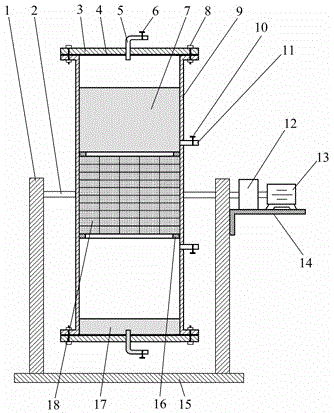

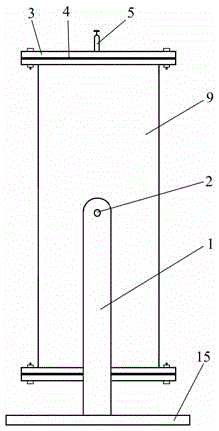

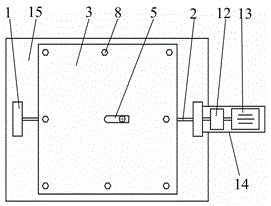

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

[0019] Such as Figure 1~Figure 4 As shown, a piezo-infiltration coating device suitable for porous ceramic-based photocatalytic packing block, its structure includes a reaction tank device, a rotating shaft 2, an air intake pipe 5, an exhaust pipe 11, a support frame 1, a base 15, a motor 13 and a reduction box 12; wherein the reaction tank body 9 in the reaction tank device is a cuboid hollow tank body, and end caps 3 are installed at both ends of the reaction tank body 9 to seal the tank body; Fixed on the support frame 1, the support frame 1 is fixed on the base 15, and the reaction tank device can be rotated on the base 15; the lining plate 16 is installed inside the reaction tank body 9, and the porous ceramic block 18 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com