Method for synthesizing bismuth vanadate photocatalyst through starch self-combustion

A self-propagating combustion and photocatalyst technology, applied in chemical instruments and methods, separation methods, light water/sewage treatment, etc., to achieve the effects of improving photocatalytic activity, broadening the absorption range, and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

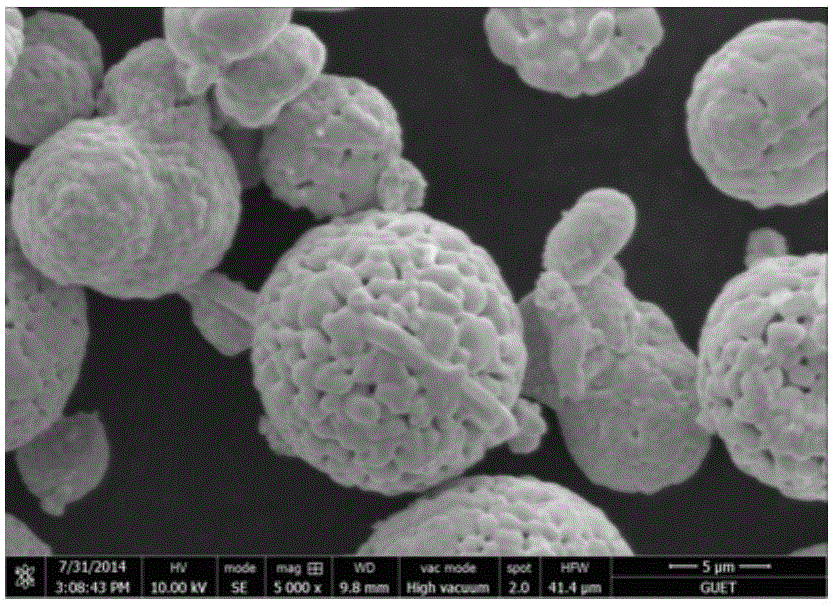

Image

Examples

Embodiment 1

[0036] A kind of method utilizing self-propagating combustion of starch to prepare bismuth spherical vanadate in network shape granules comprises the following process steps:

[0037] (1) Add 0.01mol of BiNO 3 ·5H 2 O (4.8507g) dissolved in 5mL of 4mol / L dilute nitric acid, 0.01mol of NH 4 VO 3 (1.1698g) was dissolved in 30mL of deionized water, and stirred at room temperature at a speed of 150r / min for 15min to obtain a bismuth salt solution and a vanadium salt solution;

[0038] (2) Slowly pour the dissolved vanadium salt solution into the bismuth salt solution, adjust the pH to 0.7 with concentrated ammonia water, and stir the mixed solution at room temperature at a speed of 350r / min for 30min to obtain a mixed solution;

[0039] (3) Add 6g of soluble starch to the mixed solution, and keep stirring at a speed of 200r / min for 1 hour to obtain a paste solution;

[0040] (4) Put the obtained pasty mixed solution into a crucible, put it into a muffle furnace, raise the temp...

Embodiment 2

[0047] A kind of method utilizing self-propagating combustion of starch to prepare bismuth spherical vanadate in network shape granules comprises the following process steps:

[0048] (1) Add 0.01mol of BiNO 3 ·5H 2 O (4.8507g) dissolved in 5mL of 4mol / L dilute nitric acid, 0.01mol of NH 4 VO 3 (1.1698g) was dissolved in 40mL of deionized water, and stirred at room temperature at a speed of 350r / min for 15min to obtain a bismuth salt solution and a vanadium salt solution;

[0049] (2) Slowly pour the above-dissolved vanadium salt solution into the bismuth salt solution, adjust the pH to 0.75 with concentrated ammonia water, and stir the mixed solution at room temperature at a speed of 150r / min for 30min to obtain a mixed solution;

[0050] (3) Add 6g of soluble starch to the mixed solution, and keep stirring at a speed of 200r / min for 1 hour to obtain a paste solution;

[0051] (4) Put the obtained pasty mixed solution into a crucible, put it into a muffle furnace, raise t...

Embodiment 3

[0055] A kind of method utilizing self-propagating combustion of starch to prepare bismuth spherical vanadate in network shape granules comprises the following process steps:

[0056] (1) Add 0.01mol of BiNO 3 ·5H 2 O (4.8507g) dissolved in 5mL of 4mol / L dilute nitric acid, 0.01mol of NH 4 VO 3 (1.1698g) was dissolved in 30mL of deionized water, and stirred at room temperature at a speed of 200r / min for 15min to obtain a bismuth salt solution and a vanadium salt solution;

[0057] (2) Slowly pour the dissolved vanadium salt solution into the bismuth salt solution, adjust the pH to 0.7 with concentrated ammonia water, and stir the mixed solution at room temperature at a speed of 300r / min for 30min to obtain a mixed solution;

[0058] (3) Add 6g of soluble starch to the mixed solution, and keep stirring at a speed of 200r / min for 1h to obtain a paste solution;

[0059] (4) Put the obtained pasty mixed solution into a crucible, put it into a muffle furnace, raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com