Silver nanowire/graphene composite elastic aerogel, and preparation method and application thereof

A graphene composite, silver nanowire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of high compressibility, adjustable resistance, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

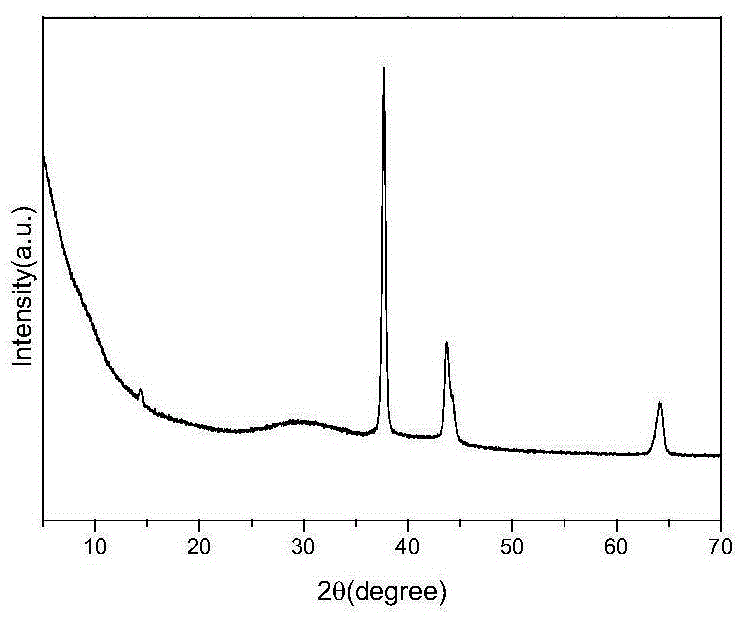

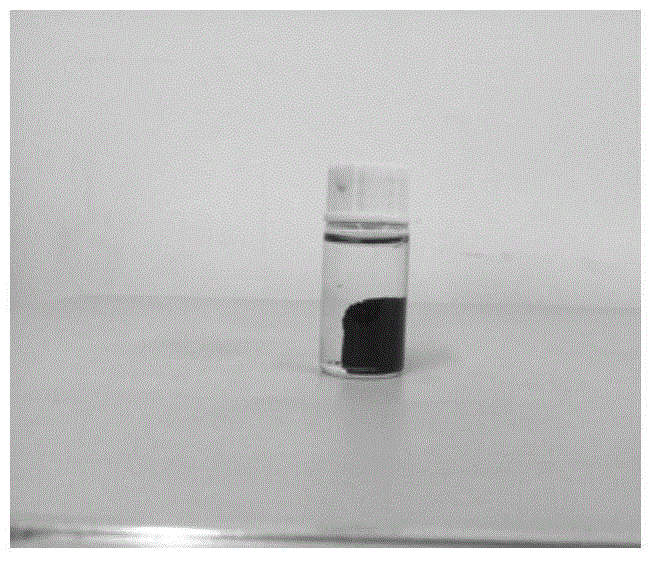

[0029] Silver nanowire / graphene composite elastic airgel of the present invention, its preferred embodiment is:

[0030] A three-dimensional network cross-linked structure built with graphene as the skeleton, silver nanowires distributed on the surface of graphene as elastic support and conductive enhancement unit, airgel density 0.5-300mg / cm 3 , compressibility 20% to 85%, electrical conductivity 10 -2 ~10 3 S / m.

[0031] The gel preparation method of silver nanowire / graphene composite elastic air-gel of the present invention, its preferred embodiment is:

[0032] Include the following steps:

[0033] (1) dispersing graphene oxide in deionized water of different weight parts to form a graphene oxide dispersion with a concentration of 0.1 to 30 mg / mL;

[0034] (2) dispersing the silver nanowires in deionized water with different weight parts to form a silver nanowire dispersion with a concentration of 0.05 to 30 mg / mL;

[0035] (3) mixing the graphene oxide dispersion liq...

Embodiment 1

[0056] A preparation method of silver nanowire / graphene composite elastic airgel, the specific steps are as follows:

[0057] (1) dispersing graphene oxide in deionized water to form a concentration of 2.0mg / mL graphene oxide dispersion;

[0058] (2) dispersing the silver nanowires in deionized water to form a silver nanowire dispersion with a concentration of 1.0 mg / mL;

[0059] (3) Mix the graphene oxide dispersion with the silver nanowire dispersion, and mechanically stir for 0.5h to obtain a silver nanowire-graphene oxide mixed dispersion;

[0060] (4) Add the silver nanowire-graphene oxide mixed dispersion obtained in step (3) into sodium bisulfite (the mass ratio of sodium bisulfite to graphene oxide is 1:30), put it in a water bath, and heat it at 95°C Reduction 8h obtains silver nanowire / graphene hydrogel;

[0061] (5) Put the silver nanowire / graphene composite hydrogel obtained in step (4) into ammonia water with a concentration of 14%, soak for 3 days, and remove t...

Embodiment 2

[0065] (1) dispersing graphene oxide in deionized water to form a concentration of 5.0mg / mL graphene oxide dispersion;

[0066] (2) dispersing the silver nanowires in deionized water to form a silver nanowire dispersion with a concentration of 1.0 mg / mL;

[0067] (3) Mix the graphene oxide dispersion with the silver nanowire dispersion, and magnetically stir for 1.0 h to obtain a silver nanowire-graphene oxide mixed dispersion;

[0068] (4) Add ascorbic acid (the mass ratio of ascorbic acid to graphene oxide is 1:50) to the silver nanowire-graphene oxide mixed dispersion obtained in step (3), put it in a water bath, and reduce it at 95°C for 3 hours to obtain silver nanowires - graphene hydrogel;

[0069] (5) Put the silver nanowire / graphene composite hydrogel obtained in step (4) into ammonia water with a concentration of 10%, soak for 5 days, and remove the residual impurities of the reaction;

[0070] (6) The silver nanowire / graphene composite hydrogel obtained in step (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com